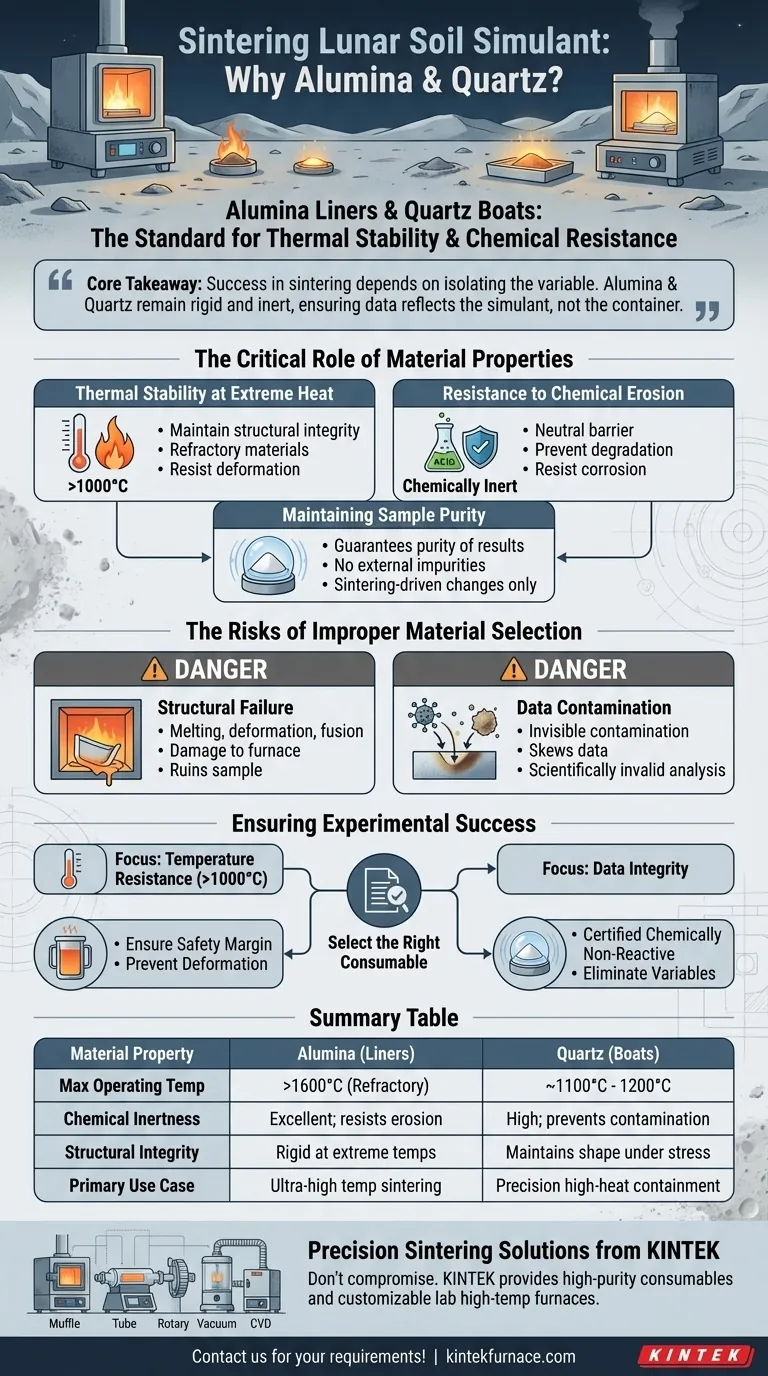

Alumina liners and quartz boats are the standard choice for sintering lunar soil simulant because they provide essential thermal stability and chemical resistance. These materials are specifically selected to withstand temperatures exceeding 1000°C without structurally failing, while simultaneously preventing chemical reactions that would contaminate the sample.

Core Takeaway: Success in sintering experiments depends on isolating the variable being tested. Alumina and quartz are utilized because they remain physically rigid and chemically inert at extreme heat, ensuring that experimental data reflects the true properties of the lunar simulant rather than interactions with the container.

The Critical Role of Material Properties

Thermal Stability at Extreme Heat

Sintering processes for lunar soil simulants often require temperatures exceeding 1000°C.

At these elevated temperatures, many standard laboratory materials would soften, melt, or deform. Alumina and quartz are refractory materials, meaning they maintain their structural integrity and shape even under intense thermal stress.

Resistance to Chemical Erosion

High temperatures often accelerate chemical reactions between contact materials.

Alumina liners and quartz boats possess superior resistance to chemical erosion. They act as a neutral barrier, ensuring that the container itself does not degrade or corrode when in contact with the hot, potentially reactive simulant.

Maintaining Sample Purity

The primary goal of using these specific consumables is to guarantee the purity of experimental results.

Because these materials do not react chemically with the lunar soil simulant, they prevent external impurities from leaching into the sample. This ensures that any observed changes in the simulant are due to the sintering process itself, free from interference caused by the container.

The Risks of Improper Material Selection

Structural Failure

Using materials with lower thermal thresholds creates a significant risk of containment failure.

If a boat or liner loses its structural integrity during the heating phase, it may collapse or fuse with the heating elements. This not only ruins the sample but can cause catastrophic damage to the furnace equipment.

Data Contamination

The most subtle but dangerous risk in sintering experiments is invisible contamination.

If a container reacts even slightly with the simulant, it introduces foreign chemical elements into the soil matrix. This interference skews the data, rendering the analysis of the sintered lunar soil simulant scientifically invalid.

Ensuring Experimental Success

To obtain accurate data from your high-temperature experiments, selecting the right consumable is a foundational step.

- If your primary focus is Temperature Resistance (>1000°C): Ensure your chosen vessel allows for a safety margin above your target temperature to prevent structural deformation.

- If your primary focus is Data Integrity: Prioritize materials like alumina and quartz that are certified to be chemically non-reactive with your specific soil simulant composition.

By using high-grade alumina and quartz, you eliminate variables and ensure the fidelity of your research.

Summary Table:

| Material Property | Alumina (Liners) | Quartz (Boats) |

|---|---|---|

| Max Operating Temp | >1600°C (Refractory) | ~1100°C - 1200°C |

| Chemical Inertness | Excellent; resists erosion | High; prevents sample contamination |

| Structural Integrity | Rigid at extreme temperatures | Maintains shape under thermal stress |

| Primary Use Case | Ultra-high temp sintering | Precision high-heat containment |

Precision Sintering Solutions from KINTEK

Don't compromise your research with substandard consumables. KINTEK provides high-purity alumina liners and quartz boats specifically designed for the rigorous demands of lunar soil simulant research.

Backed by expert R&D and manufacturing, KINTEK offers a full suite of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other lab high-temp furnaces—all fully customizable to your unique experimental needs.

Ready to ensure the purity and integrity of your data? Contact us today to discuss your custom furnace and consumable requirements!

Visual Guide

References

- Junhao Chen, Xiao Zong. Effect of TiO2 on the Microstructure and Flexural Strength of Lunar Regolith Simulant. DOI: 10.3390/cryst14020110

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the purpose of a laboratory vacuum system in photocatalytic hydrogen evolution? Ensure Accurate Data Results

- What is the role of a high-temperature ceramic boat during phosphidation? Ensure Pure and Stable Chemical Synthesis

- Which industries commonly use graphite crucible furnaces? Essential for High-Temp, High-Purity Processes

- What functions do high-strength graphite molds serve in FAST? Optimize Titanium Alloy Consolidation Today

- What role do high-strength graphite molds play during SnSe consolidation? Essential for High-Performance Densification

- How does Energy Dispersive X-ray Spectroscopy (EDX) assist in adjusting furnace parameters? Biochar Quality Control

- What are the common uses for Alumina ceramic tubes? Ideal for High-Temp, Insulation, and Corrosion Resistance

- What is the function of graphite stirring rods in aluminum casting? Achieve Perfect Alloy Homogenization