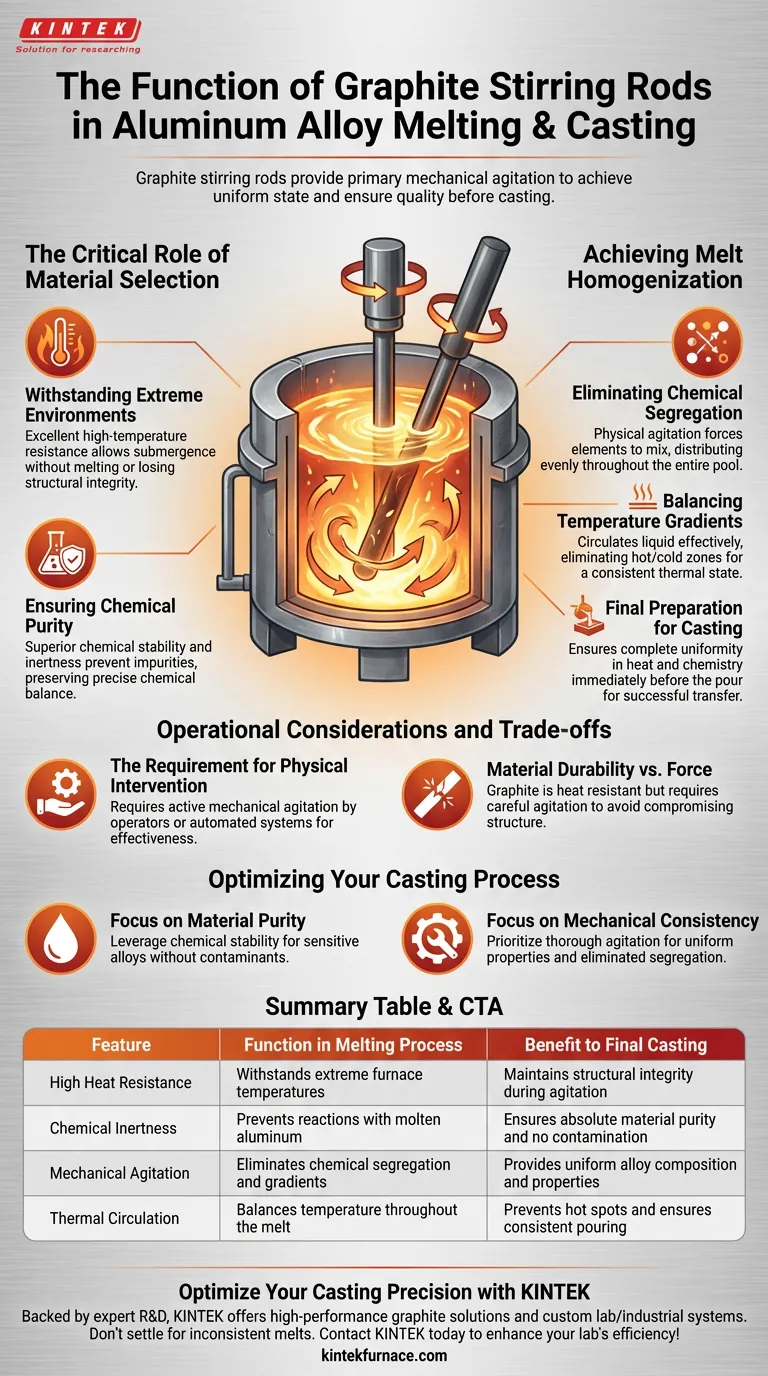

Graphite stirring rods serve as the primary mechanism for mechanical agitation within the melt pool of aluminum-based alloys. Their function is to physically mix the molten liquid to achieve a uniform state immediately prior to casting, ensuring the final product meets strict quality standards regarding composition and structure.

Achieving a high-quality cast requires more than just melting metal; it requires stability and uniformity. Graphite stirring rods provide the necessary physical agitation to homogenize the alloy's temperature and chemical composition while ensuring absolute purity through their chemical inertness.

The Critical Role of Material Selection

Withstanding Extreme Environments

The environment inside a melting furnace is hostile. Graphite is specifically employed because of its excellent high-temperature resistance.

This property allows the rod to remain submerged in the molten aluminum for the duration of the agitation process without melting or losing structural integrity.

Ensuring Chemical Purity

In alloy casting, introducing foreign elements can ruin the material properties. Graphite offers superior chemical stability.

This inertness ensures that no impurities are introduced into the melt. The rod does not react with the aluminum, preserving the precise chemical balance of the alloy.

Achieving Melt Homogenization

Eliminating Chemical Segregation

Left undisturbed, the different elements within an alloy can separate based on density. This creates a chemically uneven product.

The physical agitation provided by the graphite rod forces these elements to mix. This eliminates chemical segregation, ensuring the alloying elements are distributed evenly throughout the entire pool.

Balancing Temperature Gradients

Molten metal does not naturally maintain a uniform temperature; it develops hot spots and cooler zones.

Stirring the pool circulates the liquid effectively. This movement eliminates temperature gradients, bringing the entire volume of liquid to a consistent thermal state.

Final Preparation for Casting

The ultimate function of the rod is to bring the liquid to a state of complete homogenization.

This must occur right before the pour. By ensuring the liquid is uniform in both heat and chemistry, the rod prepares the alloy for a successful transfer into the mold.

Operational Considerations and Trade-offs

The Requirement for Physical Intervention

While graphite rods are effective, they require active mechanical agitation.

This implies that the melting process cannot be entirely passive. Operators or automated systems must actively engage the melt pool to derive the benefits of the rod; simply placing it in the melt is insufficient.

Material Durability vs. Force

Graphite is highly heat resistant but can be mechanically sensitive depending on the grade.

While the reference highlights high-temperature resistance, the physical act of agitation requires care. The goal is to move the heavy liquid without subjecting the rod to forces that might compromise its structure during the stir.

Optimizing Your Casting Process

To ensure the highest quality aluminum castings, apply these principles based on your specific production goals:

- If your primary focus is material purity: Leverage the chemical stability of graphite to mix sensitive alloys without the risk of introducing contaminants.

- If your primary focus is mechanical consistency: Prioritize thorough agitation to eliminate chemical segregation and thermal gradients, ensuring the final part has uniform properties.

By utilizing graphite stirring rods effectively, you ensure the melt is chemically precise and thermally stable before it ever reaches the mold.

Summary Table:

| Feature | Function in Melting Process | Benefit to Final Casting |

|---|---|---|

| High Heat Resistance | Withstands extreme furnace temperatures | Maintains structural integrity during agitation |

| Chemical Inertness | Prevents reactions with molten aluminum | Ensures absolute material purity and no contamination |

| Mechanical Agitation | Eliminates chemical segregation and gradients | Provides uniform alloy composition and properties |

| Thermal Circulation | Balances temperature throughout the melt | Prevents hot spots and ensures consistent pouring |

Optimize Your Casting Precision with KINTEK

Achieving superior material properties requires equipment that performs under pressure. Backed by expert R&D and manufacturing, KINTEK offers high-performance graphite solutions along with Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable for your unique lab or industrial high-temperature needs.

Don't settle for inconsistent melts. Let our experts help you select the right tools to ensure chemical stability and thermal homogenization in your production.

Contact KINTEK today to enhance your lab's efficiency!

Visual Guide

References

- Compositional Design, Microstructure, and Thermal Processing of Aluminum-Based Complex Concentrated Alloys. DOI: 10.3390/cryst15010088

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

People Also Ask

- How does an infrared (IR) pyrometer improve thermal control? Direct Precision for MBE Growth and Annealing

- Why use high-purity graphite for β-Ga2O3 annealing? Key to Thermal Precision & Safety

- What is the point of a vacuum chamber? Achieve Absolute Control in Your Processes

- What is the tank capacity of the water circulating vacuum pump? Find the Perfect Fit for Your Lab

- What is the primary role of laboratory furnaces in manufacturing and scientific processes? Unlock Precision Thermal Control

- Where are water circulating vacuum pumps commonly used? Essential for Lab and Industrial Vapor Handling

- Why is a BN coating used in Mg3Sb2 melting? Essential Purity and Protection Guide

- How can the temperature resistance of alumina ceramic furnace tubes be assessed? Ensure Long-Term Reliability in Your Lab