At its core, a vacuum chamber is a tool for achieving absolute control. Its purpose is to create a sealed, low-pressure space by removing air and other gaseous matter. This "empty" environment is not the goal itself, but rather a necessary condition for carrying out highly sensitive manufacturing or research processes that would otherwise be impossible in a normal atmosphere.

The true value of a vacuum chamber is not in creating an empty space, but in eliminating the reactive and contaminating particles present in the air. This allows processes involving extreme heat or molecular-level precision to occur without interference from the surrounding environment.

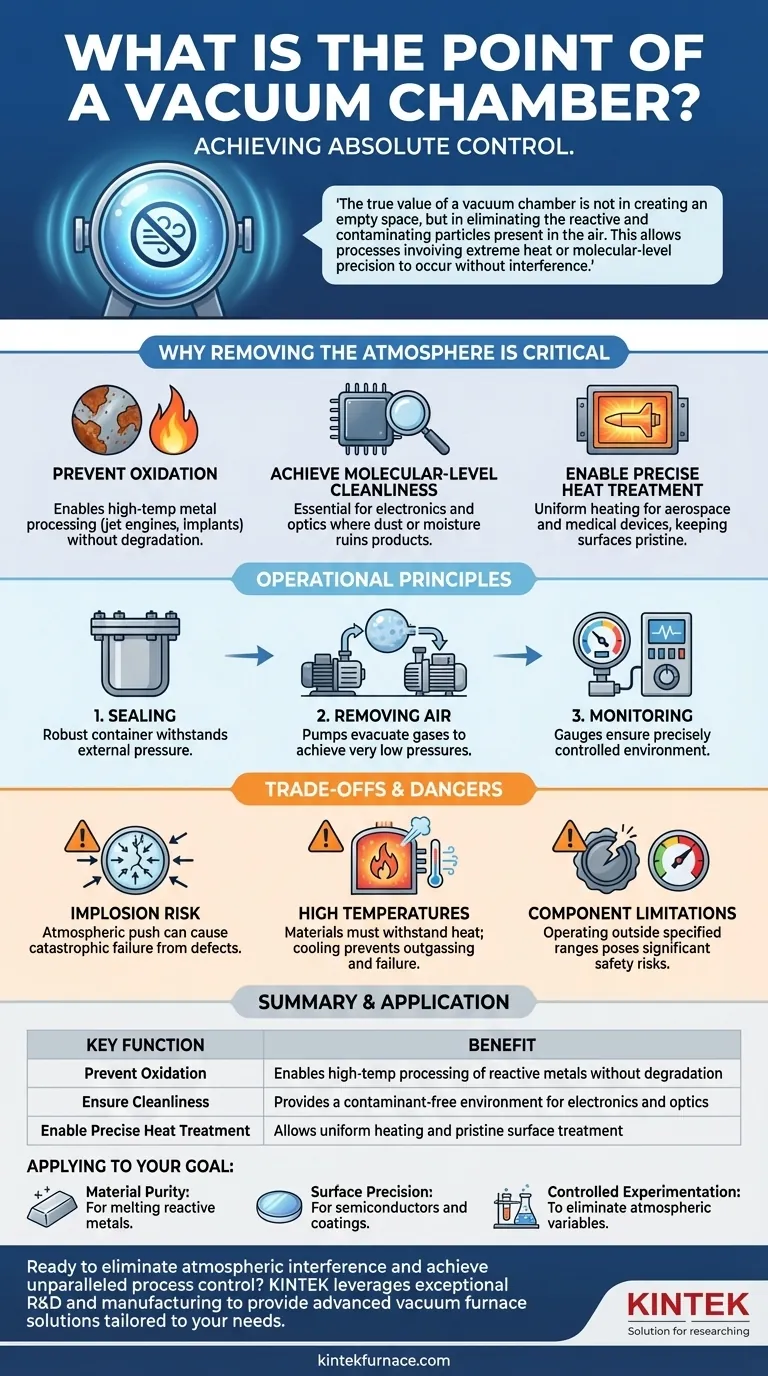

Why Removing the Atmosphere is Critical

The air around us seems harmless, but for many advanced technical processes, it is a significant contaminant. A vacuum chamber's primary function is to remove this contamination.

To Prevent Unwanted Chemical Reactions

Many materials, especially metals, react aggressively with oxygen and other gases at high temperatures. This process, known as oxidation, can degrade material properties, cause surface contamination, and lead to component failure.

By removing the atmosphere, a vacuum chamber furnace allows metals to be heated, melted, and treated without these destructive chemical reactions. This is essential for creating the high-strength, pure alloys used in jet engines and medical implants.

To Achieve Molecular-Level Cleanliness

In fields like electronics and optics, even microscopic dust particles or thin films of atmospheric moisture can ruin a product. Processes like sintering electronic components or applying thin-film coatings require an environment free of any foreign matter.

A vacuum chamber provides this ultra-clean setting, ensuring that the only materials present are the ones intended for the process. This guarantees the purity and structural integrity of the final product.

To Enable Precise Heat Treatment

Combining a vacuum with a furnace unlocks advanced heat treatment capabilities. This is critical for shaping and strengthening materials used in aerospace, medical devices, and even art preservation.

The vacuum ensures the heat is applied uniformly and that the material's surface remains pristine, without the discoloration or degradation that would occur if heated in open air.

The Operational Principles of a Vacuum System

Creating and maintaining a vacuum is a multi-stage process that requires precise engineering and constant monitoring.

1. Sealing the Environment

The process begins with a robust, sealed container, typically made of durable materials like stainless steel. This chamber must be strong enough to withstand the immense external atmospheric pressure pushing against its walls once the interior is evacuated.

2. Removing Air and Lowering Pressure

One or more vacuum pumps are used to remove air and other gases from the chamber. Different types of pumps are often used in sequence to first remove the bulk of the air (roughing pumps) and then achieve very low pressures (high-vacuum pumps).

3. Monitoring and Control

Throughout the process, pressure gauges monitor the level of vacuum inside the chamber. This allows operators to ensure the desired pressure has been reached and is maintained, providing the precise control needed for the experiment or manufacturing task.

Understanding the Trade-offs and Dangers

While powerful, vacuum chambers are complex systems with significant operational challenges and safety considerations, especially when combined with high heat.

The Implosion Risk

A vacuum does not "pull," but rather the external atmosphere "pushes" on the chamber walls. For a large chamber at sea level, this force can be equivalent to several tons. Any defect in the chamber's structure, viewports, or seals can lead to a catastrophic failure known as an implosion, where the walls collapse inward violently.

The Challenge of High Temperatures

Introducing high heat multiplies the complexity. The chamber materials must be able to withstand extreme temperatures without warping, cracking, or releasing trapped gases, a phenomenon called outgassing which can spoil the vacuum.

Many high-temperature chambers include integral cooling channels to protect seals and maintain the structural integrity of the chamber itself, preventing a thermal runaway that could lead to failure.

Component and Material Limitations

Every component—from the chamber body to the seals and power feedthroughs—must be rated for the intended pressure and temperature. Using a chamber or component outside of its specified operational range, such as heating a chamber not rated for high temperatures, poses a significant safety risk.

Applying This to Your Goal

A vacuum chamber is the correct tool when atmospheric interference is the primary obstacle to achieving your objective.

- If your primary focus is material purity: A vacuum furnace is essential for melting, brazing, or treating reactive metals to create clean, strong parts for aerospace or metal injection molding.

- If your primary focus is surface precision: A vacuum system is non-negotiable for manufacturing semiconductors, applying optical coatings, or conducting surface science research where molecular contamination would invalidate the results.

- If your primary focus is controlled experimentation: A vacuum chamber allows you to eliminate atmospheric variables, ensuring that your test results are a direct consequence of the parameters you are studying.

Ultimately, a vacuum chamber provides the power to define the environment, not just work within it.

Summary Table:

| Key Function | Benefit |

|---|---|

| Prevent Oxidation | Enables high-temperature processing of reactive metals without degradation |

| Ensure Cleanliness | Provides a contaminant-free environment for electronics and optics manufacturing |

| Enable Precise Heat Treatment | Allows uniform heating and pristine surface treatment for aerospace and medical components |

Ready to eliminate atmospheric interference and achieve unparalleled process control? At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced vacuum furnace solutions tailored to your unique needs. Whether you require a standard Muffle or Tube Furnace, or a highly customized Vacuum & Atmosphere Furnace or CVD/PECVD System, our deep customization capability ensures your process runs with precision and purity. Contact us today to discuss how our vacuum solutions can enhance your lab's capabilities and drive your research or production forward.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- How does a vacuum heat treatment furnace prevent contamination? Ensure Purity in High-Temperature Processes

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- Why should nitrogen not be used as a cooling gas for titanium alloys in vacuum heat treatment? Avoid Catastrophic Failures

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment