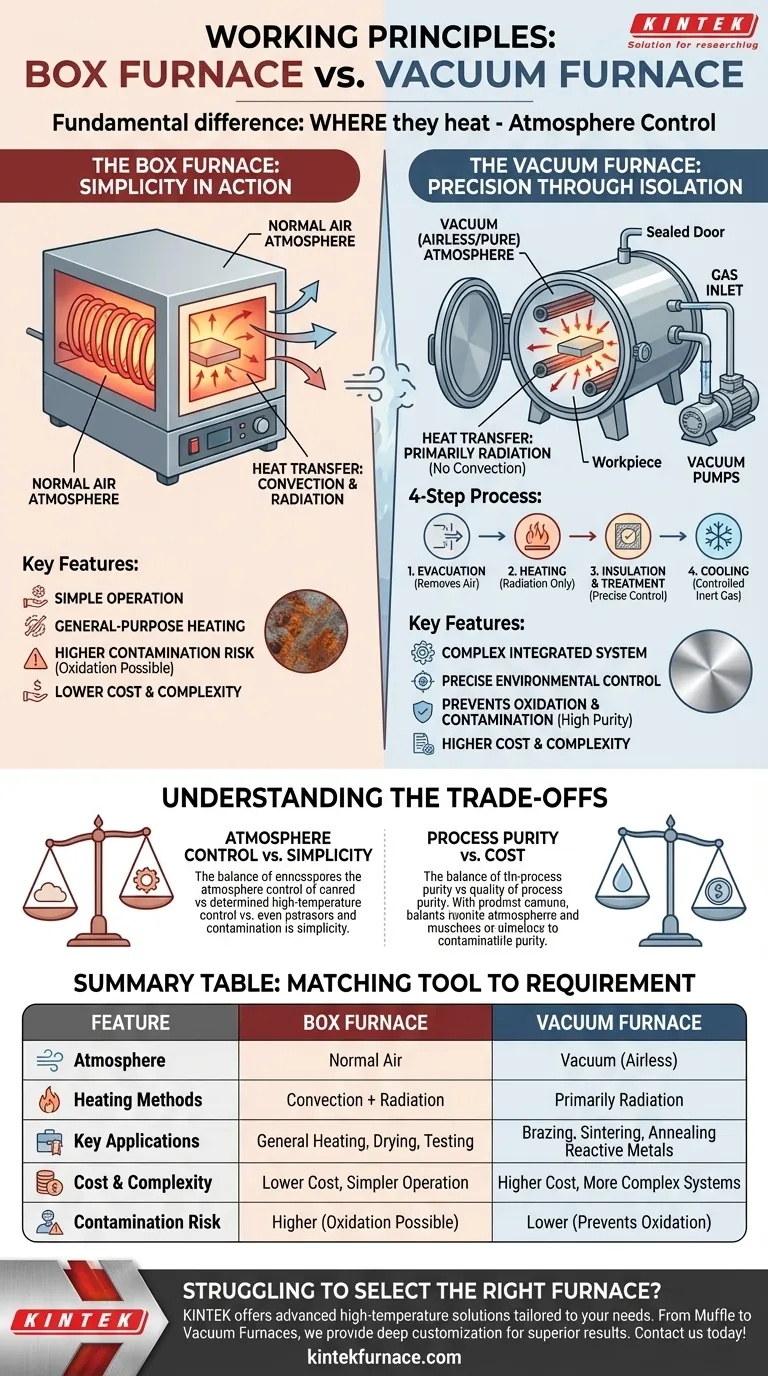

At its core, a box furnace heats materials in a normal air atmosphere, while a vacuum furnace first removes the air to create a controlled, pure environment before heating. The box furnace operates much like a conventional oven, using both hot air (convection) and direct heat (radiation). In contrast, a vacuum furnace isolates the material from oxygen and other atmospheric gases, which is critical for preventing oxidation and contamination during high-temperature processes.

The fundamental difference is not just how they heat, but where they heat. A box furnace works in the open atmosphere, making it simple and versatile. A vacuum furnace creates an artificial, airless environment, enabling high-purity processes that are impossible in the presence of air.

The Box Furnace: Simplicity in Action

A box furnace is the workhorse for general-purpose thermal processing. Its design prioritizes ease of use, reliability, and operational simplicity for applications where atmospheric exposure is not a concern.

How It Heats: Convection and Radiation

A box furnace heats its chamber using electric heating elements. Heat is transferred to the workpiece through two primary methods working together.

Radiation is the direct transfer of heat from the hot elements to the material. Convection is the transfer of heat through the movement of the hot air inside the chamber. A controllable chimney often helps manage airflow and exhaust.

Key Structural Components

The design is straightforward and robust. It typically consists of a simple box-shaped chamber, often made of stainless steel, containing the heating elements and insulation.

The furnace and its control system are often separate units, simplifying maintenance and operation. An intelligent temperature controller manages the heating cycle.

The Role of the Atmosphere

Operating in ambient air is the defining characteristic of a box furnace. This makes it ideal for processes like chemical analysis, basic heat treatments, and drying, where reactions with oxygen or nitrogen are either desired or inconsequential.

The Vacuum Furnace: Precision Through Isolation

A vacuum furnace is a highly specialized tool designed for processes that demand absolute environmental control. By removing the atmosphere, it prevents unwanted chemical reactions at elevated temperatures.

The Four-Step Working Principle

The operation of a vacuum furnace is a precise, multi-stage process.

- Evacuation: The vacuum system, using a series of pumps, removes air and other gases from the sealed chamber to achieve the desired sub-atmospheric pressure.

- Heating: Once the vacuum is established, electric heating elements (often made of graphite or specialized metals) raise the temperature.

- Insulation & Treatment: The material is held at a specific temperature for a set duration to complete the process, such as annealing or brazing.

- Cooling: The material is cooled in a controlled manner, often by introducing an inert gas like nitrogen or argon back into the chamber to speed up the process.

Why a Vacuum Is Necessary

Air contains approximately 21% oxygen, which is highly reactive at high temperatures. This reactivity causes oxidation (like rust on steel), which can ruin sensitive materials and components.

By removing the air, a vacuum furnace eliminates the risk of oxidation and other forms of contamination, ensuring the material's surface finish and structural integrity remain pristine.

Core Systems: A Complex Integration

A vacuum furnace is not a single component but an integrated system.

- The Vacuum System: Uses multiple pumps (e.g., mechanical, diffusion) to create and maintain the vacuum.

- The Heating System: Employs high-performance resistance elements to generate heat efficiently in a vacuum.

- The Control System: Precisely regulates temperature, pressure, and process timing for repeatable, high-quality results.

Understanding the Trade-offs

Choosing between these furnaces means weighing the need for environmental control against the need for simplicity and cost-effectiveness.

Atmosphere Control vs. Simplicity

A vacuum furnace offers unparalleled control over the processing environment, preventing oxidation and contamination. This control comes at the cost of increased complexity in both equipment and operation.

A box furnace is far simpler to operate and maintain but offers no protection from the surrounding atmosphere.

Process Purity vs. Cost

The sophisticated systems required for a vacuum furnace—including vacuum pumps, sealed chambers, and advanced controls—make it significantly more expensive than a box furnace.

This higher cost is justified only when process purity is a critical requirement that cannot be achieved in a standard atmosphere.

Heat Transfer Differences

In a box furnace, both convection (air movement) and radiation contribute to heating. In a vacuum furnace, the near-total lack of air means convection is eliminated.

Heating occurs almost exclusively through radiation. This can affect how uniformly an object heats, especially complex shapes, and must be accounted for in process design.

Making the Right Choice for Your Process

Your choice depends entirely on the material you are processing and the outcome you need to achieve.

- If your primary focus is general-purpose heating, drying, or material testing where air exposure is acceptable: The simplicity and low cost of a box furnace make it the ideal choice.

- If your primary focus is brazing, sintering, annealing, or heat-treating reactive metals that must be protected from oxidation: The environmental control of a vacuum furnace is non-negotiable.

- If your primary focus is budget and operational ease for non-sensitive materials: A box furnace provides the most direct path to your goal.

- If your primary focus is achieving the highest purity, best surface finish, and maximum process repeatability for sensitive applications: A vacuum furnace offers the necessary precision.

Ultimately, selecting the correct furnace is about matching the tool's environment to your material's specific processing requirements.

Summary Table:

| Feature | Box Furnace | Vacuum Furnace |

|---|---|---|

| Atmosphere | Normal air | Vacuum (airless) |

| Heating Methods | Convection and radiation | Primarily radiation |

| Key Applications | General heating, drying, material testing | Brazing, sintering, annealing reactive metals |

| Cost and Complexity | Lower cost, simpler operation | Higher cost, more complex systems |

| Contamination Risk | Higher (oxidation possible) | Lower (prevents oxidation and contamination) |

Struggling to select the right furnace for your lab's thermal processes? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're working with general materials or sensitive applications requiring high purity, we can help you achieve superior results. Contact us today to discuss how our furnaces can enhance your lab's efficiency and performance!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- Why is a high-vacuum system required for PVD of doped hydroxyapatite? Achieve High-Purity Biomedical Coatings

- What is the regulatory function of a vacuum drying oven? Master Catalyst Preparation and Distribution Control

- How does industrial thermal analysis simulation software optimize directional solidification? Elevate Casting Precision

- What key process conditions do high-temperature vacuum furnaces provide for the thermal hydrogen treatment of Ti–6Al–4V?

- How is vacuum brazing applied in the medical field? Achieve Superior Biocompatibility and Strength for Devices

- What are the technical advantages of vacuum Spark Plasma Sintering (SPS) systems? Advanced SiC Ceramic Densification

- What role does an automated hardness tester play in evaluating steel component gas quenching processes? Verify Quality

- How are vacuum furnaces applied in semiconductor manufacturing? Essential for Purity and Precision in Chip Fabrication