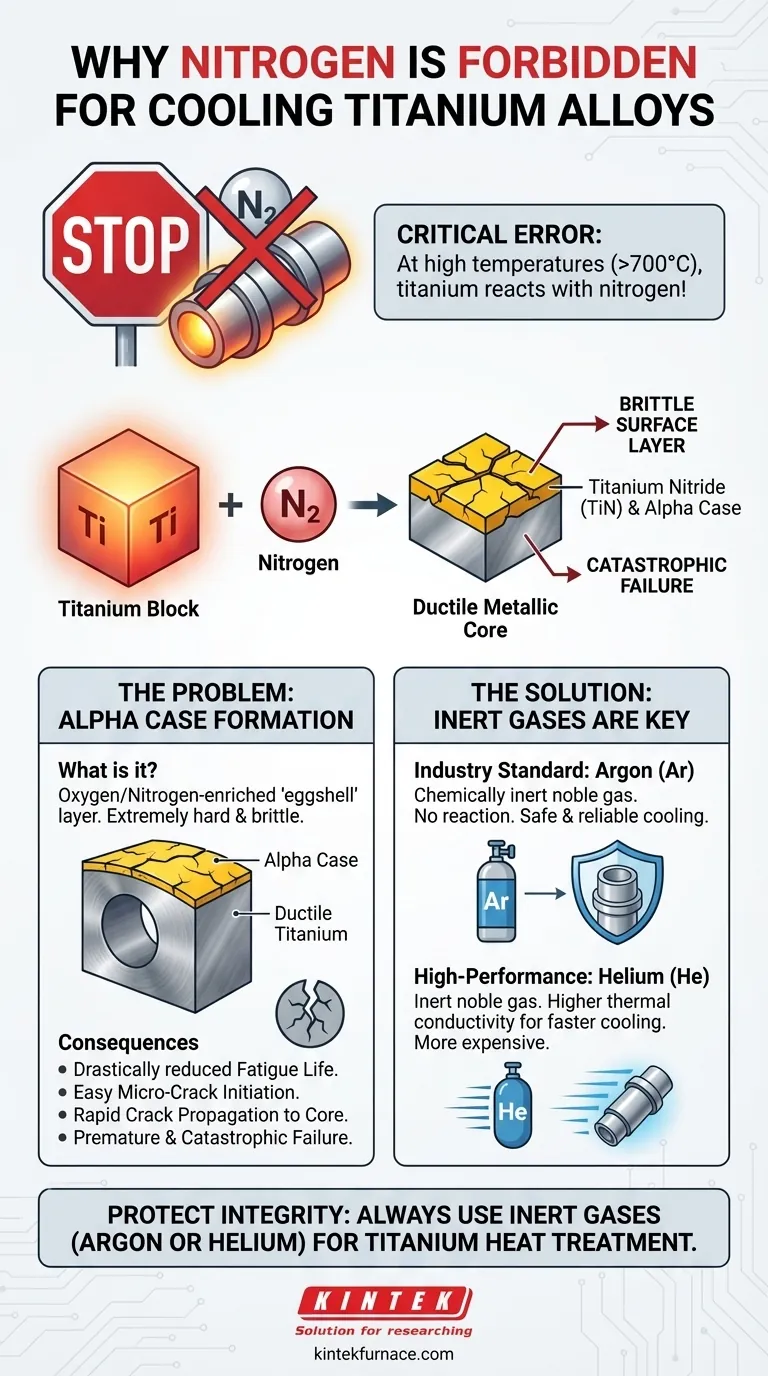

Under no circumstances should nitrogen be used as a cooling gas for titanium alloys following high-temperature vacuum heat treatment. At the elevated temperatures involved in these processes, titanium has a high affinity for nitrogen and reacts directly with it. This chemical reaction forms a hard, brittle surface layer that fundamentally compromises the integrity of the component.

While nitrogen is a common and cost-effective gas in many heat-treating applications, its use with titanium is a critical error. The reaction creates a failure-prone surface layer known as "alpha case," which negates the very benefits the heat treatment process is meant to impart.

The Fundamental Chemical Conflict

The issue with using nitrogen is not one of contamination in the traditional sense, but of a direct, detrimental chemical reaction. Titanium's reactivity at high temperatures is the core of the problem.

The Formation of Titanium Nitride (TiN)

At temperatures typically exceeding 700°C (1300°F), titanium readily reacts with any available nitrogen. This forms a distinct, golden-yellow compound on the surface of the part called titanium nitride (TiN).

While TiN is used beneficially as a hard coating in other applications (like on cutting tools), its uncontrolled formation during heat treatment is highly undesirable.

Creating the "Alpha Case"

This nitrogen-rich surface layer is known as alpha case. It is an oxygen- and/or nitrogen-enriched layer that is extremely hard and brittle compared to the ductile titanium alloy substrate beneath it.

The depth of this alpha case depends on the temperature, time, and partial pressure of the nitrogen, but even a thin layer can be catastrophic for the component's performance.

Why Alpha Case is Detrimental to Performance

The formation of an alpha case is one of the most severe defects in titanium metallurgy. It creates a composite material where a brittle "eggshell" is bonded to a tough core, a combination primed for failure.

Reduced Fatigue Life

The primary danger of alpha case is its drastic reduction of fatigue life. The brittle surface cannot handle cyclic loading. Micro-cracks initiate easily within the alpha case and act as sharp stress risers.

Initiation Point for Catastrophic Failure

Once a crack forms in the brittle alpha case, it can quickly propagate into the tough, ductile parent metal underneath. This can lead to premature and often catastrophic failure of the component, even under loads it was designed to withstand.

Negating the Heat Treatment's Purpose

The entire goal of heat treating titanium is to produce a specific microstructure that delivers optimal properties like strength, ductility, and fatigue resistance. Allowing alpha case to form works directly against this goal, ruining the component's surface integrity and rendering the heat treatment ineffective, or worse, harmful.

Understanding the Correct Alternatives

Protecting titanium during the critical cooling phase requires a gas that is truly inert and will not react with the alloy at any temperature.

The Industry Standard: Argon (Ar)

Argon is the most widely used and recommended gas for quenching titanium in a vacuum furnace. It is a noble gas, meaning it is chemically inert and will not react with titanium. It provides a safe and reliable method for cooling parts without forming an alpha case.

The High-Performance Option: Helium (He)

Helium is also a completely inert noble gas. Its primary advantage over argon is its much higher thermal conductivity, which allows for faster cooling rates. This rapid quench can be critical for developing desired properties in certain thick-sectioned or high-strength titanium alloys. However, helium is significantly more expensive and less common.

Making the Right Choice for Your Process

Selecting the correct backfill gas is not a matter of preference but a critical process parameter for ensuring part quality and safety.

- If your primary focus is safety and reliability: Always use Argon. It is the inert, industry-standard gas that guarantees no adverse surface reactions with titanium alloys.

- If your primary focus is achieving maximum cooling rates for specific properties: Use Helium. Its superior thermal conductivity provides a faster quench, but be prepared for significantly higher operational costs.

- If you are ever considering nitrogen to save costs: Do not. The risk of creating a brittle alpha case and causing catastrophic component failure far outweighs any potential savings on gas.

Protecting the metallurgical integrity of your titanium components begins with selecting a truly inert gas for all high-temperature operations.

Summary Table:

| Aspect | Description |

|---|---|

| Issue with Nitrogen | Reacts with titanium at high temperatures, forming a brittle alpha case layer. |

| Consequences | Reduced fatigue life, crack initiation, and catastrophic failure of components. |

| Safe Alternatives | Argon (inert, reliable) and Helium (faster cooling, higher cost). |

| Key Takeaway | Always use inert gases to prevent surface reactions and ensure part integrity. |

Ensure your titanium heat treatments are safe and effective with KINTEK's advanced solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs. Contact us today to discuss how we can enhance your process reliability and performance!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the main applications of multi-chamber continuous vacuum furnaces? Boost High-Volume Industrial Efficiency

- What densification mechanism does oscillatory pressure sintering introduce? Harness Shear Forces for h-BN Ceramics

- What types of materials and processes are compatible with vacuum furnaces? Achieve Purity and Precision in Heat Treatment

- How does the vacuum environment benefit material processing? Achieve Superior Purity and Control

- Why is vacuum brazing considered a clean process? Achieve Oxide-Free, Flux-Free Metal Joining

- What advantages does a laboratory vacuum oven offer over a conventional oven for Pb SA/OSC catalyst drying?

- How does a vacuum heat treatment furnace improve thermal spray coatings? Enhance Bond Strength & Surface Purity.

- What is the classification of a vacuum furnace? Match Performance, Process & Temperature to Your Needs