At their core, water circulating vacuum pumps are workhorses for laboratories and small-scale industrial processes that require a modest vacuum. They are most commonly found in academic, chemical, pharmaceutical, biological, and foodstuff industries for applications like vacuum distillation, evaporation, filtration, and degassing where solvent vapors are present.

These pumps are not chosen for creating the deepest vacuum. Instead, their value lies in their remarkable simplicity, reliability, and their inherent ability to handle condensable vapors and corrosive gases that would damage or contaminate more sensitive, oil-sealed pump systems.

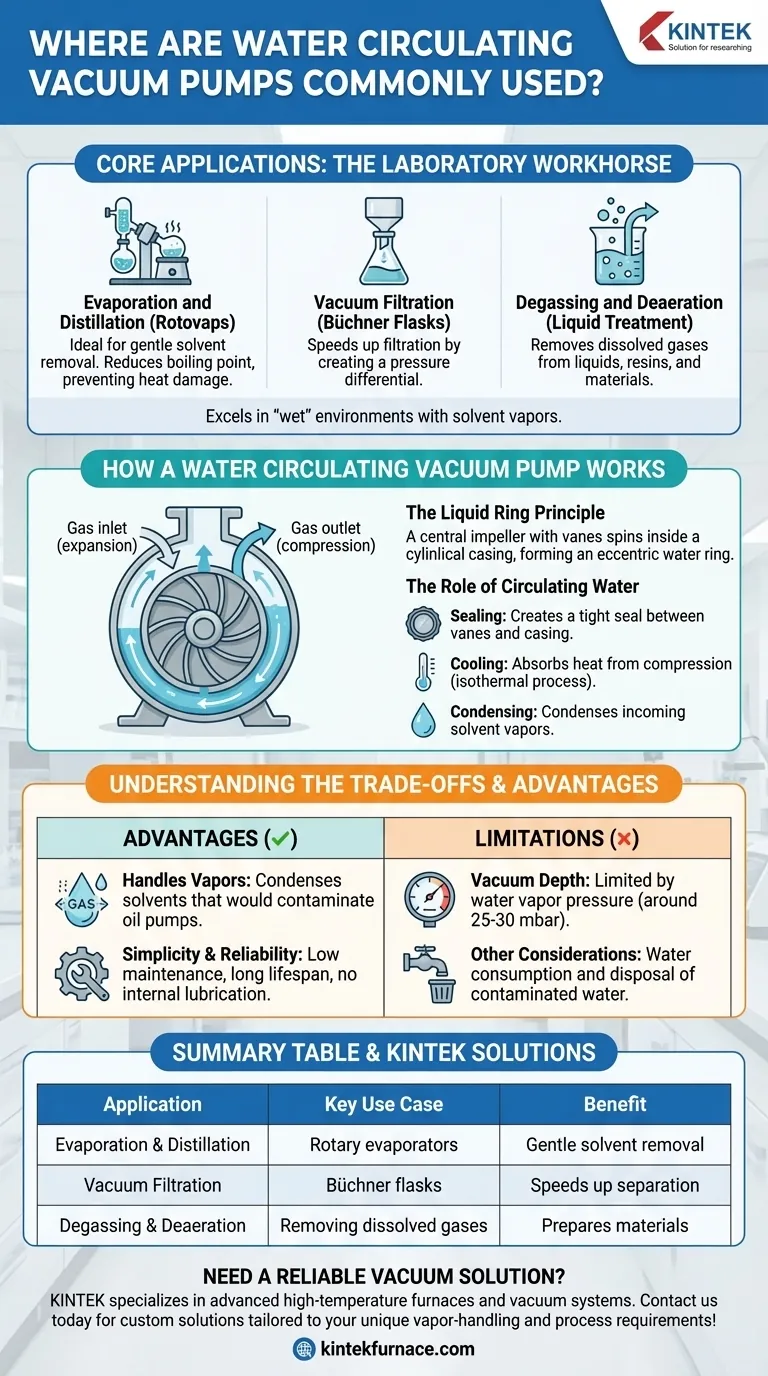

Core Applications: The Laboratory Workhorse

Water circulating vacuum pumps, also known as liquid ring vacuum pumps, excel in environments where the gas being removed is "wet"—meaning it's mixed with vapors, often from solvents or water itself.

Evaporation and Distillation

In chemistry and pharmaceutical production, reducing pressure lowers the boiling point of liquids. These pumps are ideal for rotary evaporators ("rotovaps") and distillation setups, allowing for the gentle removal of solvents without excessive heat that could damage the product.

Vacuum Filtration

These pumps are frequently connected to Büchner flasks to speed up filtration. By creating a pressure differential across the filter paper, the pump pulls the liquid through quickly, leaving the solid residue behind.

Degassing and Deaeration

Removing dissolved gases from liquids is a common requirement before analysis or further processing. These pumps are used to "pull" dissolved air out of solvents, polymer resins, and other materials.

How a Water Circulating Vacuum Pump Works

Understanding their function clarifies why they are suited for these specific tasks and not others. It's a simple, elegant design that uses a liquid (usually water) to create the vacuum.

The Liquid Ring Principle

Inside the pump, an impeller with vanes spins eccentrically within a cylindrical casing. As it spins, centrifugal force throws the circulating water against the outer wall, forming a stable "liquid ring."

Because the impeller is off-center, the space between the impeller hub and the liquid ring continuously expands and contracts. Gas is drawn in on the expanding side (creating the vacuum) and compressed and pushed out on the contracting side.

The Role of the Circulating Water

The water is the key to the entire operation. It performs three critical functions:

- Sealing: It creates a tight seal between the impeller vanes and the casing.

- Cooling: It absorbs the heat generated from compressing the gas (an isothermal process), keeping the pump cool.

- Condensing: It condenses vapors from the incoming gas stream, which is a major advantage when working with solvents.

Distinguishing from Standard Water Circulators

It is crucial to understand that these are not the same as the circulating pumps used in HVAC or domestic hot water systems. Those pumps simply move liquid within a closed loop to transfer heat. A water circulating vacuum pump uses the moving liquid to actively trap and remove gas from a system.

Understanding the Trade-offs and Advantages

No technology is perfect for every situation. The strengths of a water circulating vacuum pump in one context become its limitations in another.

Key Advantage: Handling Vapors

This is their primary benefit. Solvent or water vapors that would contaminate the oil in a traditional rotary vane pump are simply condensed into the circulating water ring and expelled. This makes them perfect for wet chemistry.

Key Advantage: Simplicity and Reliability

Their design is simple, with low precision requirements and no need for internal lubrication. This translates to high reliability, low maintenance, and a long operational lifespan.

Primary Limitation: Vacuum Depth

The deepest vacuum a water circulating pump can achieve is limited by the vapor pressure of the water itself. As the pressure in the system approaches the water's vapor pressure (around 25-30 mbar at room temperature), the water in the ring will begin to boil, preventing a deeper vacuum.

Other Considerations

These pumps consume water, which may need to be replenished or run in a closed loop with a chiller to maintain temperature and conserve water. Furthermore, if used to pump corrosive or toxic gases, the resulting contaminated water must be disposed of properly.

Making the Right Choice for Your Application

Selecting the correct vacuum pump requires matching its capabilities to your specific goal.

- If your primary focus is general lab chemistry (distillation, filtration, evaporation): A water circulating vacuum pump is an excellent, robust, and cost-effective choice due to its unmatched ability to handle solvent vapors.

- If your primary focus is achieving high or ultra-high vacuum (<1 mbar): This is the wrong tool. You need a dry scroll pump, an oil-sealed rotary vane pump, or a multi-stage system with a turbomolecular pump.

- If your primary focus is a low-maintenance, reliable vacuum for "wet" processes: The simplicity and vapor-handling capabilities of a water circulating vacuum pump make it a leading contender.

Ultimately, understanding the pump's operating principle empowers you to use it effectively for its intended purpose and know when a different solution is required.

Summary Table:

| Application | Key Use Case | Benefit |

|---|---|---|

| Evaporation and Distillation | Rotary evaporators and distillation setups | Gentle solvent removal without excessive heat |

| Vacuum Filtration | Büchner flasks for rapid liquid separation | Speeds up filtration process |

| Degassing and Deaeration | Removing dissolved gases from liquids | Prepares materials for analysis or processing |

Need a reliable vacuum solution for your lab? KINTEK specializes in advanced high-temperature furnaces and vacuum systems. With exceptional R&D and in-house manufacturing, we offer products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, tailored to your unique needs through deep customization. Enhance your experimental efficiency—contact us today to discuss how we can support your vapor-handling and other process requirements!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the primary function of a quartz tube in SnSe preparation? Ensure High-Purity Alloy Synthesis

- What are the advantages of using high-purity platinum crucibles? Ensure Absolute Data Integrity in Magnetite Oxidation

- Why are silicon carbide crucibles selected for C95800 aluminum bronze? Ensure Purity & Efficiency

- What is the temperature range for Laboratory Type Furnaces? Find Your Ideal Heat Solution

- Is there a need to add water when launching the circulating water multifunctional vacuum pump? Ensure Optimal Performance and Avoid Damage

- What roles do high-purity graphite molds play in the SPS of copper sulfide? Enhance Your Thermoelectric Material Quality

- Why is a ceramic crucible necessary for the thermal processing of silica extracted from sugarcane bagasse?

- How does a laboratory drying oven contribute to the preparation of C@TiC/SiO2 xerogels? Ensure Structural Integrity