While the immediate answer is no, you do not need to add water every single time you launch the circulating water vacuum pump. This is because the pump operates using a self-contained water reservoir. The critical task is not adding water at every startup, but rather ensuring this reservoir is adequately filled before you begin your work.

The core principle to understand is that the pump cannot function without water. The instruction to not add water "when launching" assumes the internal tank is already filled from a previous session or initial setup. Your primary responsibility is to check the water level before operation, not to add water ritualistically at every power-on.

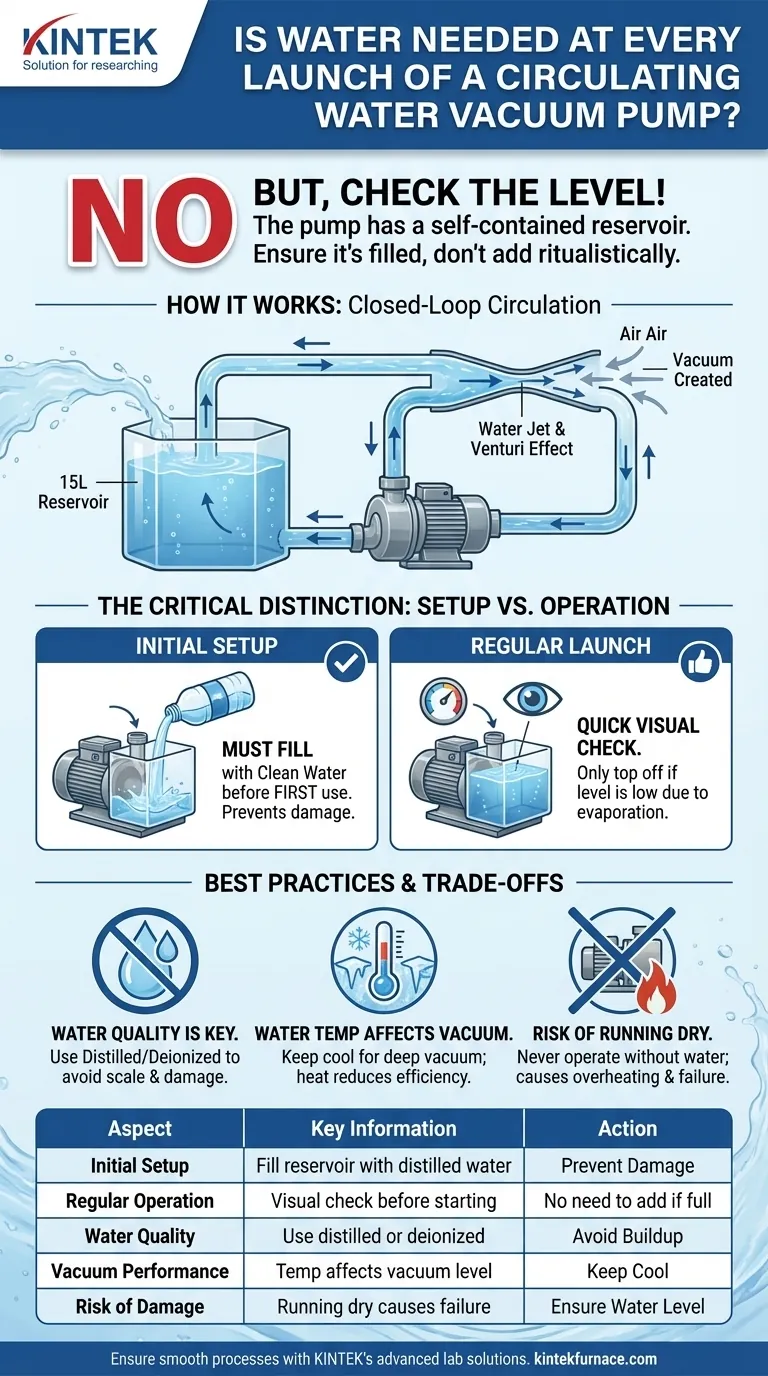

How the Circulating Water System Works

A circulating water vacuum pump is an elegant and clean alternative to oil-sealed pumps. Its operation is based on a simple physical principle, using water as its only working fluid.

The Role of the Water Reservoir

The pump contains a built-in water tank, which can have a capacity of around 15 liters. This tank holds the water that the pump will use to generate a vacuum. This water is not consumed in the process but is continuously circulated.

Creating Vacuum with Water Jets

Inside the pump, a motor propels the stored water at high velocity through a special nozzle called a jet or an ejector. As the water stream accelerates through this constriction, its pressure drops dramatically, creating a low-pressure zone (a vacuum).

This principle, known as the Venturi effect, pulls air or gas from any connected lab equipment, such as a distillation or filtration apparatus. The air mixes with the water stream and is then expelled, while the water returns to the reservoir to be circulated again.

Why "Circulating" Matters

The term "circulating" is key. The pump is a closed-loop system for the water. This design makes it efficient and "pollution-free" because it doesn't use oil that can contaminate your system or require messy disposal. The only loss is typically minor evaporation over long operating periods.

The Critical Distinction: Initial Fill vs. Regular Operation

The confusion in your question stems from the difference between setting the pump up for the first time and using it for a routine procedure.

The Initial Setup

Before a circulating water pump is used for the very first time, its internal reservoir must be filled with clean water. Operating the pump without water will prevent it from creating a vacuum and can potentially damage the motor or internal components.

The Pre-Launch Checklist

"Launching" the pump refers to turning it on for a specific task. If the pump was used recently, the water tank will still be full. Therefore, you don't need to add water.

Your pre-launch checklist should be a quick visual inspection of the water level in the tank. If the level is sufficient, you can proceed. You only need to top it off if the level has dropped due to evaporation or if you have changed the water.

Understanding the Trade-offs and Best Practices

To get reliable performance from your pump, it's crucial to understand its operational nuances.

Water Quality is Key

Using distilled or deionized water is highly recommended. Tap water contains minerals that can build up as scale inside the pump's components over time, reducing efficiency and eventually causing damage.

Water Temperature Affects Vacuum

The ultimate vacuum a water pump can achieve (e.g., -0.098 MPa) is limited by the vapor pressure of the water itself. As the water heats up during prolonged operation, its vapor pressure increases, which slightly reduces the maximum vacuum level the pump can attain. For deep vacuum applications, keeping the water cool is beneficial.

The Risk of Running Dry

Never operate the pump without sufficient water in the reservoir. Running it dry is the most common and preventable cause of pump failure. It can cause the motor to overheat and the seals to fail.

How to Ensure Proper Operation

Follow these simple guidelines to ensure consistent and reliable performance from your circulating water vacuum pump.

- If you are setting up the pump for the first time: Fill the water tank with clean, preferably distilled, water to the manufacturer's recommended level.

- If you are starting a new procedure: Always perform a quick visual check of the water level in the reservoir before turning the pump on.

- If you are running a long process: Periodically check the water level to compensate for any evaporation and consider changing the water if it becomes excessively warm or contaminated.

Properly maintaining the water level is the single most important factor for the longevity and reliability of your pump.

Summary Table:

| Aspect | Key Information |

|---|---|

| Initial Setup | Fill reservoir with distilled water before first use to prevent damage. |

| Regular Operation | Check water level visually before starting; no need to add water if full. |

| Water Quality | Use distilled or deionized water to avoid mineral buildup and scaling. |

| Vacuum Performance | Water temperature affects vacuum level; keep cool for deep vacuum applications. |

| Risk of Damage | Running pump dry can cause motor overheating and seal failure. |

Ensure your lab's vacuum processes run smoothly with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique experimental needs. Contact us today to discuss how our reliable equipment can enhance your efficiency and precision!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What function do high-strength graphite molds serve? Essential Roles in Ti-6Al-4V Vacuum Hot Pressing

- How does a high-precision heating stage contribute to the drying and crystallization of FAPbBr3 nanosheets?

- Why is a vacuum pump utilized in research concerning the reaction of magnesium with carbon dioxide and nitrogen? Ensure Data Integrity

- What are the main features of a water circulating vacuum pump compared to a desktop pump? Discover Key Differences for Your Lab

- What is the function of an in-situ heating holder in the study of Peierls transitions in NaRu2O4? Dynamic Lab Insights

- What are the maximum working pressure specifications for water circulating vacuum pumps? Ensure Safe Operation and Avoid Failure

- Why are fly ash geopolymer specimens subjected to 60 °C drying? Master Accelerated Curing for Maximum Strength

- How does a Mass Flow Controller (MFC) influence CrAlSiN coatings? Precision Ar/N2 Control for Hardness