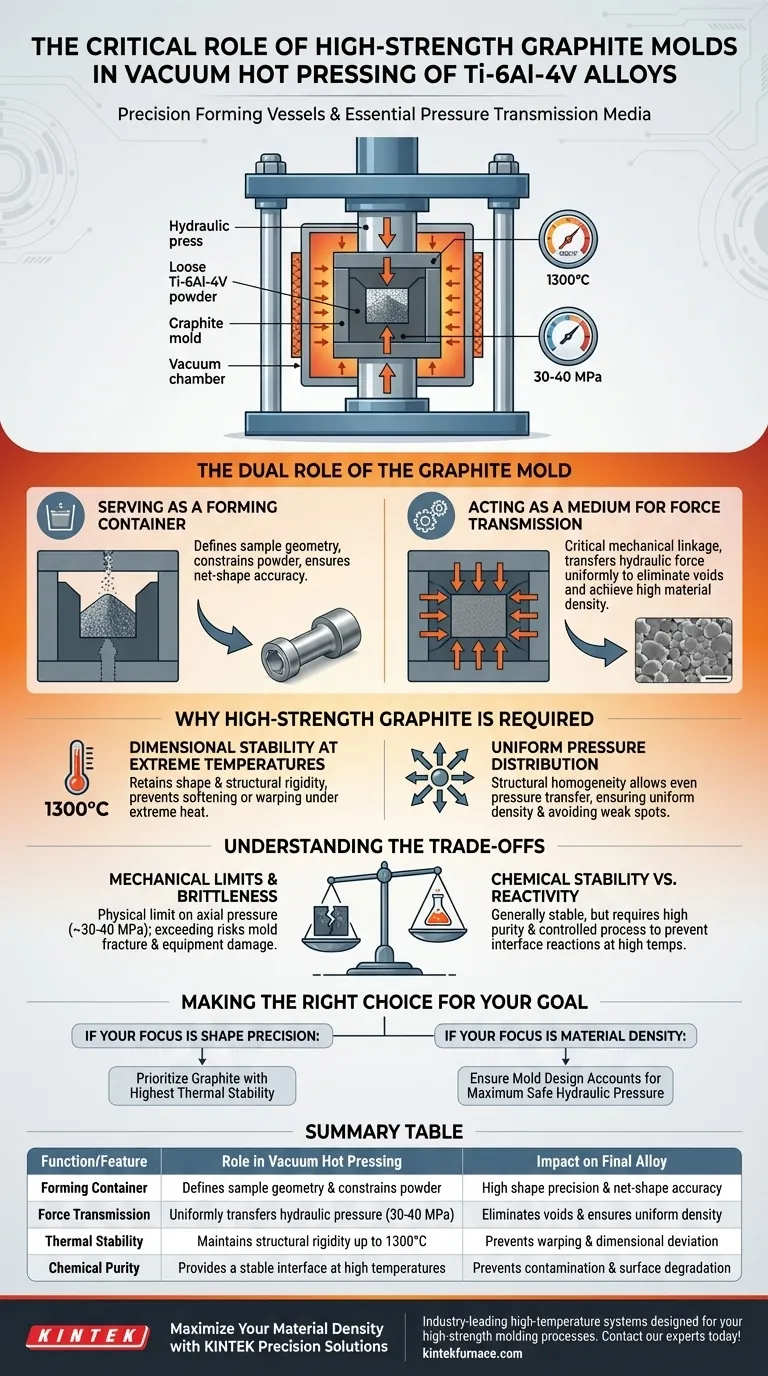

High-strength graphite molds function primarily as precision forming vessels and essential pressure transmission media. In the vacuum hot pressing of Ti-6Al-4V alloys, they contain the metal powder while uniformly transferring hydraulic force to the compact. Crucially, they must maintain precise dimensional stability under extreme thermal conditions reaching 1300°C.

These molds are not passive containers; they are active mechanical components in the densification process. By acting as a stable medium for force transmission, they directly dictate the final density, shape precision, and structural integrity of the alloy sample.

The Dual Role of the Graphite Mold

Serving as a Forming Container

The most immediate function of the mold is to act as a containment vessel for the loose Ti-6Al-4V powder.

Because the process involves extreme heat, the mold defines the geometry of the final sample. It constrains the powder, ensuring the alloy consolidates into the specific desired shape rather than spreading uncontrollably.

Acting as a Medium for Force Transmission

Beyond simple containment, the mold serves as a critical mechanical linkage between the press and the powder.

The hydraulic system applies force to the mold (often via a ram), and the mold must transmit this pressure uniformly to the powder body. This transmission is what forces the powder particles together, eliminating voids and achieving high material density.

Why High-Strength Graphite is Required

Dimensional Stability at Extreme Temperatures

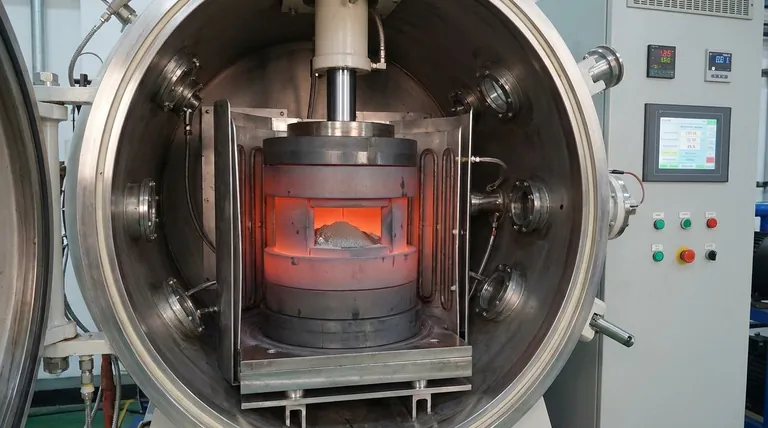

Vacuum hot pressing of Ti-6Al-4V occurs at temperatures up to 1300°C.

Standard materials would soften or warp under this thermal load. High-strength graphite retains its shape and structural rigidity in these environments, ensuring the final component meets precise dimensional tolerances.

Uniform Pressure Distribution

The quality of the final alloy depends on how evenly pressure is applied.

Graphite’s structural homogeneity allows it to transfer pressure without localized stress concentrations. This results in a sample with uniform density throughout its volume, preventing weak spots or structural inconsistencies in the final part.

Understanding the Trade-offs

Mechanical Limits and Brittleness

While graphite has excellent high-temperature strength, it is inherently brittle compared to metals.

There is a physical limit to the axial pressure the mold can withstand (typically around 30-40 MPa depending on the grade). Exceeding this limit to achieve higher density carries the risk of mold fracture, which would ruin the sample and potentially damage the pressing equipment.

Chemical Stability vs. Reactivity

Graphite is generally chemically stable, which is vital for preventing reactions with the Ti-6Al-4V powder.

However, at elevated temperatures and pressures, interface reactions can still occur if the graphite is not of high purity or if the process parameters drift. This requires a careful balance of temperature and hold time to ensure successful forming without degrading the alloy's surface properties.

Making the Right Choice for Your Goal

To optimize your vacuum hot pressing process, consider your specific manufacturing priorities:

- If your primary focus is Shape Precision: Prioritize graphite grades with the highest available thermal stability to prevent deformation at peak temperatures (1300°C).

- If your primary focus is Material Density: Ensure your mold design accounts for the maximum safe hydraulic pressure to avoid fracture while achieving optimal compaction.

The graphite mold is the defining boundary of your product; its stability determines the success of the entire sintering operation.

Summary Table:

| Function/Feature | Role in Vacuum Hot Pressing | Impact on Final Alloy |

|---|---|---|

| Forming Container | Defines sample geometry and constrains powder | High shape precision and net-shape accuracy |

| Force Transmission | Uniformly transfers hydraulic pressure (30-40 MPa) | Eliminates voids and ensures uniform density |

| Thermal Stability | Maintains structural rigidity up to 1300°C | Prevents warping and dimensional deviation |

| Chemical Purity | Provides a stable interface at high temperatures | Prevents contamination and surface degradation |

Maximize Your Material Density with KINTEK Precision Solutions

Achieving the perfect densification of Ti-6Al-4V alloys requires the right combination of high-temperature equipment and structural integrity. KINTEK provides industry-leading Muffle, Tube, Rotary, Vacuum, and CVD systems, all designed to integrate seamlessly with your high-strength molding processes. Backed by expert R&D and world-class manufacturing, our lab high-temp furnaces are fully customizable to meet your unique metallurgical needs.

Ready to enhance your lab's efficiency and sample precision? Contact our technical experts today to find the perfect thermal solution for your workflow.

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- Why are high-purity alumina boats utilized as precursor containers in MoS2 synthesis? Ensure High-Quality 2D Materials

- What role does a mass flow controller (MFC) play in gas distribution? Ensure Precision in Sensor Performance Evaluation

- How does a Mass Flow Controller (MFC) regulate TCNF morphology? Achieve Precise Carbon Nanofiber Growth

- What is the function of an alumina boat during high-temperature activation of porous carbon? Durable Lab Solutions

- Why is a high-purity graphite box required for CZTS sulfurization? Protect Thin Film Integrity and Crystallinity

- Why use a vacuum sealing device for nickelate thin films? Master the Infinite-Layer Reduction Process

- What role does a laboratory oven play in the evaluation of the physical properties of teak activated carbon? Accuracy Tips

- Why is a graphite crucible selected as the high-temperature reaction vessel? Optimize Sodium-Ion Battery Synthesis