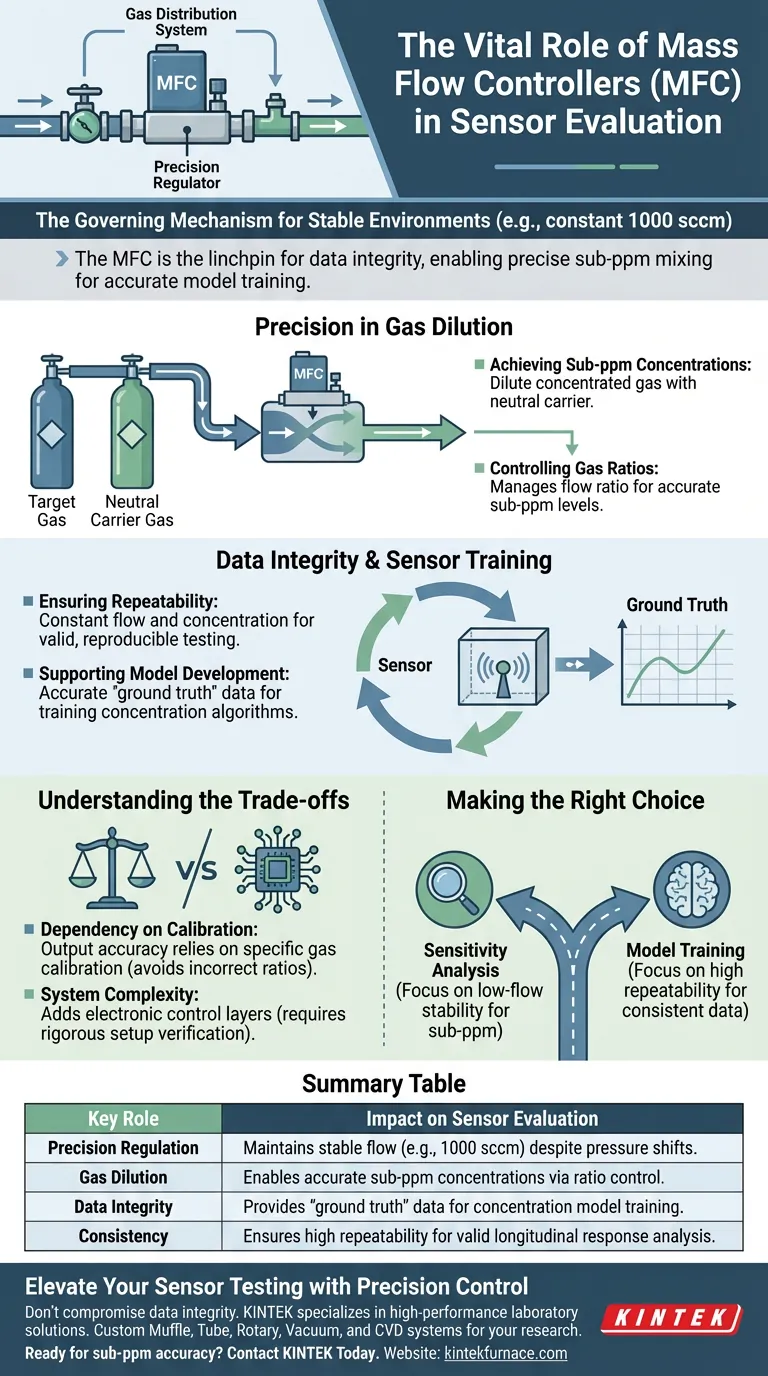

A mass flow controller (MFC) acts as the precision regulator within a gas distribution system, actively maintaining the specific flow rate of gases entering a sensor test chamber. It serves as the governing mechanism that ensures the environment remains stable, such as holding a constant flow at 1000 sccm (standard cubic centimeters per minute), regardless of pressure fluctuations.

The MFC is the linchpin for data integrity in sensor testing. By strictly controlling the ratio of target gas to dilution gas, it enables precise mixing down to sub-ppm levels, ensuring the accuracy and repeatability required to train concentration estimation models.

Precision in Gas Dilution

Achieving Sub-ppm Concentrations

To evaluate high-performance sensors, you often need to generate extremely low gas concentrations. An MFC allows you to dilute a concentrated target gas with a neutral carrier gas.

Controlling Gas Ratios

The device creates these mixtures by managing the exact flow ratio between the two gas sources. By precisely governing how much target gas enters the stream relative to the dilution gas, the MFC achieves accurate concentrations down to sub-ppm (parts per million) levels.

Data Integrity and Sensor Training

Ensuring Repeatability

For a sensor evaluation to be valid, the testing conditions must be reproducible. The MFC ensures that the flow rate and gas concentration remain constant throughout the experiment.

Supporting Model Development

Reliable sensor data is critical for developing algorithms. The precise control provided by the MFC ensures the data collected is accurate enough to serve as "ground truth" for training concentration estimation models.

Analyzing Response Characteristics

To understand how a sensor reacts to changes, you must isolate the variable of gas concentration. The MFC stabilizes the flow, allowing engineers to attribute changes in sensor output directly to the gas chemistry rather than flow artifacts.

Understanding the Trade-offs

Dependency on Calibration

While an MFC offers high precision, its output is only as good as its own calibration. If the controller drifts or is not calibrated for the specific gas being used, the calculated dilution ratios will be incorrect.

System Complexity

Introducing MFCs into a distribution system adds layers of complexity regarding control signals and power requirements. You are moving from simple mechanical regulation to active, electronic flow management, which requires rigorous setup verification.

Making the Right Choice for Your Goal

To maximize the effectiveness of your sensor evaluation setup, match your MFC strategy to your specific testing objectives.

- If your primary focus is Sensitivity Analysis: Ensure your MFC can maintain stability at extremely low flow ratios to accurately achieve sub-ppm concentrations.

- If your primary focus is Model Training: Prioritize high repeatability to ensure the data fed into your algorithms represents a consistent, reproducible reality.

The MFC is not just a valve; it is the reference standard that validates the accuracy of your entire sensor evaluation project.

Summary Table:

| Key Role | Impact on Sensor Evaluation |

|---|---|

| Precision Regulation | Maintains stable flow (e.g., 1000 sccm) despite pressure shifts. |

| Gas Dilution | Enables accurate sub-ppm concentrations via ratio control. |

| Data Integrity | Provides "ground truth" data for concentration model training. |

| Consistency | Ensures high repeatability for valid longitudinal response analysis. |

Elevate Your Sensor Testing with Precision Control

Don't let inconsistent gas flows compromise your data integrity. At KINTEK, we specialize in high-performance laboratory solutions backed by expert R&D and manufacturing. Whether you need a specialized gas distribution setup or a customizable high-temperature furnace, our team offers Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to your unique research needs.

Ready to achieve sub-ppm accuracy and repeatable results? Contact KINTEK Today to discuss your custom laboratory equipment requirements!

Visual Guide

References

- Tianci Liu, Seong Chan Jun. Hybrid Series of Carbon‐Vacancy Electrodes for Multi Chemical Vapors Diagnosis Using a Residual Multi‐Task Model. DOI: 10.1002/advs.202500412

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Ultra-High Vacuum Flange Aviation Plug Glass Sintered Airtight Circular Connector for KF ISO CF

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

People Also Ask

- What role does a PTFE-lined high-pressure autoclave play in synthesis of ZnO nanorods? Key Benefits & Growth Factors

- What are the key properties of alumina ceramic furnace tubes? Discover Their High-Temp and Chemical Resistance

- How does the integration of digital control panels and safety devices enhance industrial electric furnace operation?

- How does the temperature difference contribute to the cracking of the alumina furnace tube? Prevent Cracks for Longer Tube Life

- What is the function of a laboratory pellet press in PCM preparation? Optimize Building Energy Storage Materials

- What is the role of a mechanical vacuum pump in the preparation of FeAl alloys? Achieve 10⁻² Pa for Pure Synthesis

- What role does a high-purity alumina crucible play in BSO synthesis? Ensure Purity in High-Temperature Reactions

- Can alumina ceramic furnace tubes be customized for specific applications? Enhance Your High-Temperature Processes