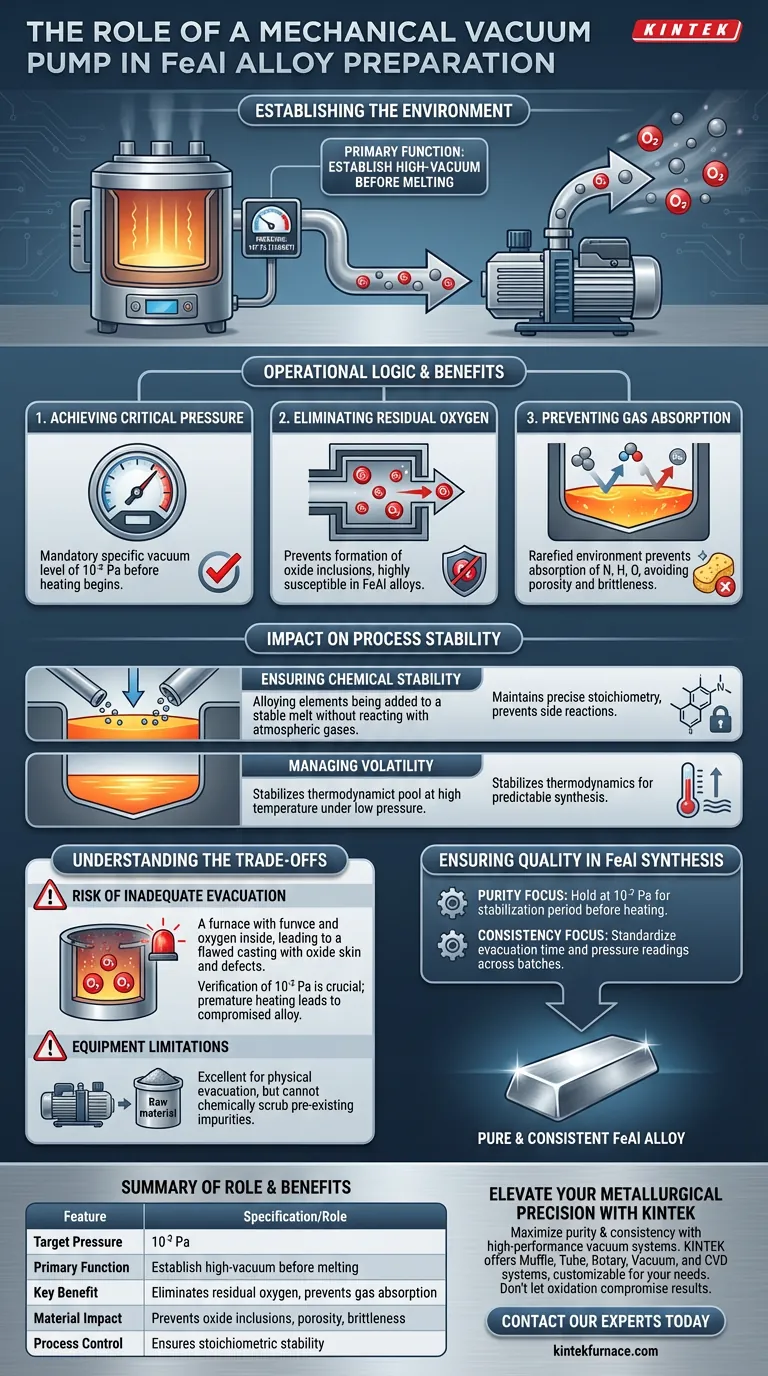

In the preparation of FeAl alloys, the mechanical vacuum pump serves a singular, critical function: establishing a high-vacuum environment within the induction furnace. Before any melting occurs, this pump operates to lower the internal chamber pressure to a specific target of 10⁻² Pa.

By establishing this low-pressure environment prior to heating, the vacuum pump creates the physical prerequisites for a pure melt. It eliminates atmospheric contaminants that would otherwise react with the molten metal, ensuring the chemical stability and structural integrity of the final alloy.

The Operational Logic of the Vacuum Process

Achieving Critical Pressure Levels

The mechanical vacuum pump is not merely an accessory; it is the primary control mechanism for the furnace atmosphere.

Its objective is to reduce the pressure to 10⁻² Pa.

Reaching this specific vacuum level is mandatory before the induction heating process can begin.

Eliminating Residual Oxygen

The most immediate benefit of this evacuation is the removal of residual oxygen from the furnace chamber.

FeAl alloys are highly susceptible to oxidation, particularly in the molten state.

By removing oxygen before the temperature rises, the pump prevents the formation of oxide inclusions that would degrade the material's properties.

Preventing Gas Absorption

Molten metals often act as "sponges" for atmospheric gases.

If the furnace environment is not evacuated, the liquid metal will absorb nitrogen, hydrogen, or remaining oxygen.

The mechanical pump ensures the environment is rarefied enough to prevent this gas absorption, which is a common cause of porosity and brittleness in the final casting.

The Impact on Process Stability

Ensuring Chemical Stability

The vacuum environment is essential for the stability of the alloying element addition process.

When adding elements to the melt, reactions with atmospheric gases can alter the stoichiometry (the precise chemical ratio) of the alloy.

The vacuum ensures that the elements you add are integrated into the alloy rather than consumed by side reactions with the air.

Managing Volatility

Certain alloying elements may react unpredictably under standard atmospheric pressure at high temperatures.

The controlled low-pressure environment stabilizes the thermodynamics of the melt.

This allows for a predictable and repeatable synthesis process.

Understanding the Trade-offs

The Risk of Inadequate Evacuation

It is insufficient to merely run the pump; the target pressure of 10⁻² Pa must be verified.

If the melting process begins before this threshold is reached, the partial pressure of oxygen may still be high enough to compromise the alloy.

This often results in a "skin" of oxide forming on the melt or internal defects that weaken the final product.

Equipment Limitations

A mechanical pump is excellent for roughing and reaching medium-to-high vacuum levels suitable for induction melting.

However, it is strictly a tool for physical evacuation.

It cannot chemically scrub impurities already present in the raw materials; it can only remove the atmospheric environment surrounding them.

Ensuring Quality in FeAl Synthesis

To maximize the effectiveness of the mechanical vacuum pump in your workflow:

- If your primary focus is Purity: Ensure the system holds at 10⁻² Pa for a stabilization period before initiating induction heating to guarantee full evacuation.

- If your primary focus is Consistency: Standardize the evacuation time and pressure readings across every batch to eliminate atmospheric variables from your data.

The mechanical vacuum pump is the gatekeeper of alloy quality, transforming a reactive furnace chamber into a neutral environment safe for precision metallurgy.

Summary Table:

| Feature | Specification/Role |

|---|---|

| Target Pressure | 10⁻² Pa |

| Primary Function | Establish high-vacuum environment before melting |

| Key Benefit | Eliminates residual oxygen and prevents gas absorption |

| Material Impact | Prevents oxide inclusions, porosity, and brittleness |

| Process Control | Ensures stoichiometric stability of alloying elements |

Elevate Your Metallurgical Precision with KINTEK

Maximize the purity and consistency of your FeAl alloys with high-performance vacuum systems. Backed by expert R&D and manufacturing, KINTEK offers high-tier Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as other lab high-temp furnaces—all fully customizable to meet your unique research and production needs.

Don't let oxidation compromise your results. Contact our technical experts today to find the perfect vacuum furnace solution for your laboratory.

Visual Guide

References

- J. Cebulski, Jadwiga Gabor. Structure and Corrosion Resistance of Fe40Al5Cr0.2TiB Alloy After Casting and After Homogenization Annealing. DOI: 10.3390/ma18020308

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

People Also Ask

- What are the advantages of water circulating vacuum pumps? Discover Oil-Free, Reliable Solutions for Clean Processes

- How does a laboratory high-temperature oven facilitate the destabilization of lignin? Optimize Biomass Pretreatment

- Why are zirconia grinding jars and milling balls ideal for Bismuth Telluride? Achieve 200nm Purity and Performance

- What processes is the circulating water multifunctional vacuum pump suitable for? Ideal for Clean, Economical Lab Vacuum Needs

- What is the primary function of a high-purity vacuum-sealed quartz tube in the Modified Bridgman technique? Key Role

- What are the functions of a high vacuum mechanical pump in Ga2O3 PETO? Ensure Purity in Film Preparation

- What is the role of quartz capillaries in the vacuum sealing process of sulfur? Enhance Purity and In-Situ Analysis

- What are the advantages of using open corundum crucibles for thermal analysis? Accurate Biomass & Coal Data