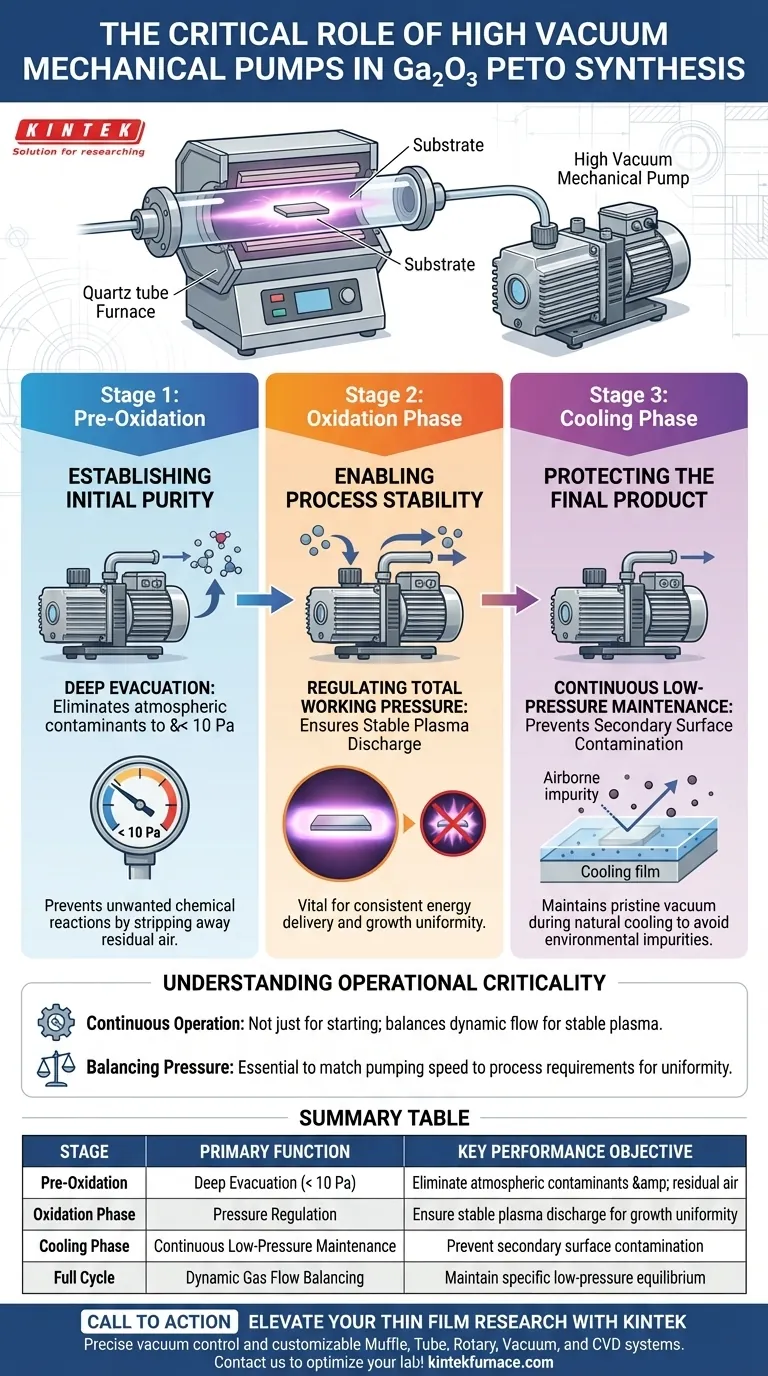

The high vacuum mechanical pump acts as the critical gatekeeper for environmental purity during the Plasma-Enhanced Thermal Oxidation (PETO) process. Its specific role is to eliminate atmospheric contaminants by evacuating the furnace to below 10 Pa prior to oxidation, regulate working pressure to sustain stable plasma discharge, and maintain a pristine vacuum during the cooling phase to prevent surface contamination.

The mechanical pump is not merely a device for removing air; it is the primary instrument for creating and sustaining the specific low-pressure equilibrium required to grow high-quality, contaminant-free Gallium Oxide thin films.

Establishing Initial Purity

Pre-Oxidation Evacuation

Before any heating or oxidation begins, the mechanical pump performs a crucial purging function.

It evacuates the tube furnace to a baseline pressure of below 10 Pa.

Eliminating Atmospheric Interference

The primary goal of this deep evacuation is to remove residual air from the chamber.

By stripping away the atmospheric background, the pump eliminates the potential for unwanted chemical reactions that could degrade the quality of the Gallium Oxide (Ga2O3) film.

Enabling Process Stability

Regulating Total Working Pressure

Once the oxidation process begins, the role of the pump shifts from simple evacuation to active regulation.

It assists in maintaining precise control over the total working pressure inside the furnace.

Ensuring Plasma Discharge Stability

This pressure control is vital for the PETO technique specifically.

Stable plasma discharge relies on a consistent pressure environment; the mechanical pump ensures the pressure remains within the specific window required to sustain the plasma.

Protecting the Final Product

Managing the Cooling Phase

The pump’s work continues even after the active oxidation phase concludes.

During the natural cooling phase, the mechanical pump continues to operate to maintain a low-pressure environment.

Preventing Secondary Contamination

This post-process operation is a defensive measure.

By maintaining a vacuum while the film cools, the pump prevents environmental impurities from re-entering the chamber and settling on the film surface, thereby avoiding secondary contamination.

Understanding Operational Criticality

The Necessity of Continuous Operation

It is a common misconception that the pump is only needed to "start" the vacuum.

In the PETO process, the pump must operate dynamically to balance the gas inlet flow against the exhaust.

Balancing Pressure for Plasma

If the pumping speed is not matched correctly to the process requirements, the plasma discharge can become unstable.

The pump must be capable of holding the pressure steady enough to prevent fluctuations that would disrupt the plasma energy delivered to the Ga2O3 film.

Optimizing the PETO Process Workflow

To ensure the highest quality Gallium Oxide thin films, consider how you utilize the pump at each stage of the experiment.

- If your primary focus is Film Purity: Ensure the initial evacuation strictly reaches the threshold of < 10 Pa to fully eliminate residual air interference.

- If your primary focus is Growth Uniformity: Monitor the pump's ability to maintain stable working pressure, as this directly dictates the consistency of the plasma discharge.

- If your primary focus is Surface Cleanliness: Do not disengage the pump immediately after oxidation; maintain the low-pressure environment throughout the entire natural cooling cycle.

The mechanical pump is the foundational tool that secures the integrity of the vacuum environment from the first moment of evacuation to the final retrieval of the sample.

Summary Table:

| Stage of PETO Process | Primary Function of Mechanical Pump | Key Performance Objective |

|---|---|---|

| Pre-Oxidation | Deep Evacuation (to < 10 Pa) | Eliminate atmospheric contaminants & residual air |

| Oxidation Phase | Pressure Regulation | Ensure stable plasma discharge for growth uniformity |

| Cooling Phase | Continuous Low-Pressure Maintenance | Prevent secondary surface contamination during cooling |

| Full Cycle | Dynamic Gas Flow Balancing | Maintain specific low-pressure equilibrium |

Elevate Your Thin Film Research with KINTEK

Precise vacuum control is the foundation of high-quality Gallium Oxide (Ga2O3) synthesis. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet the rigorous demands of your laboratory's PETO processes.

Whether you require ultra-stable pressure regulation for plasma discharge or deep evacuation for material purity, our team is ready to design a solution tailored to your unique needs. Contact us today to optimize your lab's high-temperature and vacuum capabilities!

Visual Guide

References

- Ren-Siang Jiang, Qijin Cheng. O2-to-Ar Ratio-Controlled Growth of Ga2O3 Thin Films by Plasma-Enhanced Thermal Oxidation for Solar-Blind Photodetectors. DOI: 10.3390/nano15181397

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What are the advantages of nickel crucibles for KOH activation? Ensure High Purity & Thermal Stability up to 700°C

- What role does a heated substrate platform play in the spray pyrolysis deposition? Optimize Your Thin Film Quality

- How does the integration of digital control panels and safety devices enhance industrial electric furnace operation?

- What are the technical advantages of using ZrO2 crucibles? Elevate Smelting Accuracy with Zirconium Dioxide

- What is the function of the circulating water cooling system? Optimize Pyrolysis Oil Condensation and Yield

- Why is a sintering process using a lab furnace necessary for Li6PS5Cl disks? Enhance Conductivity & Density

- What is the necessity of using a laboratory vacuum drying oven when processing Fe-N-C catalyst powders?

- How does a sealed high-purity graphite reaction box function? Optimize Sb-Ge Thin Film Selenization