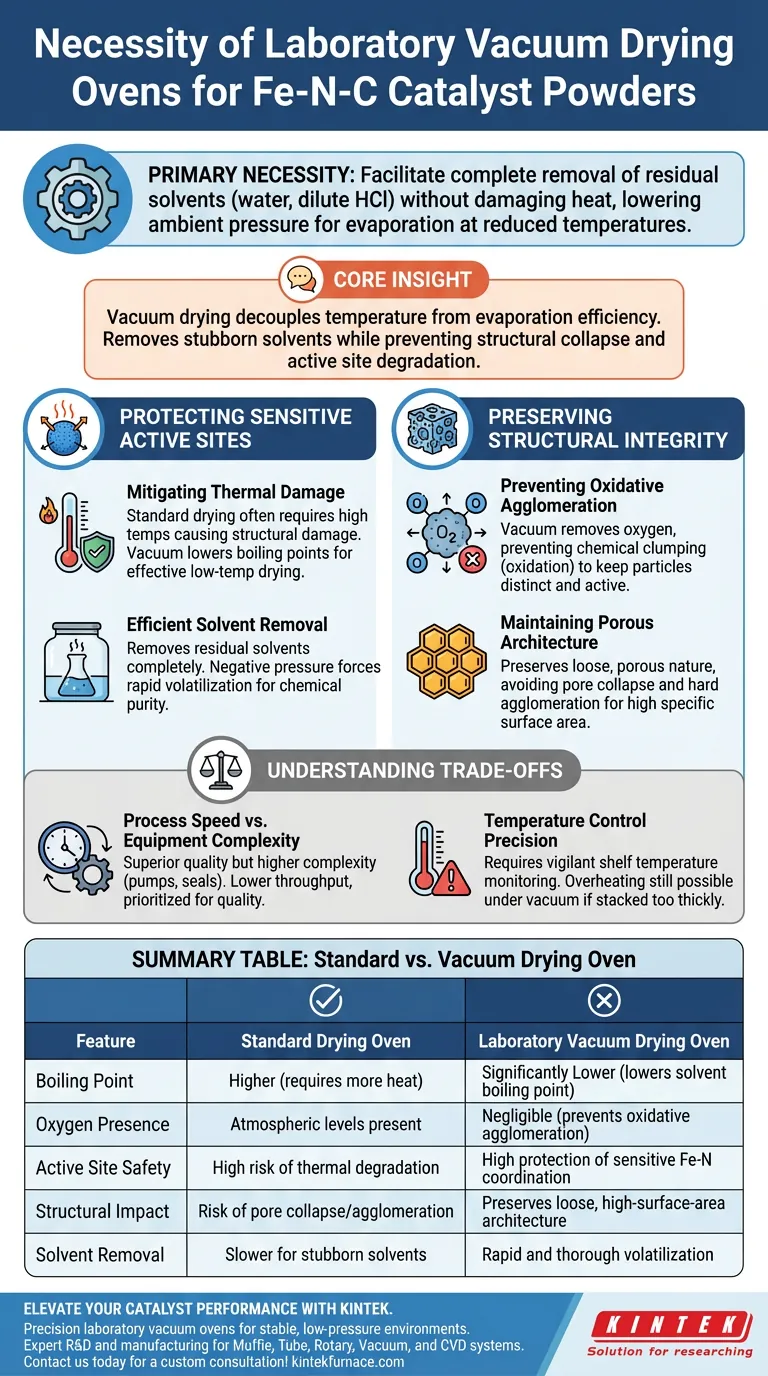

The primary necessity of a laboratory vacuum drying oven is to facilitate the complete removal of residual solvents—specifically water or dilute hydrochloric acid—from washed Fe-N-C catalyst powders without subjecting them to damaging heat. By lowering ambient pressure, the oven allows these solvents to evaporate at significantly reduced temperatures, safeguarding the material's chemical integrity.

Core Insight: Vacuum drying decouples temperature from evaporation efficiency. It allows you to remove stubborn solvents like dilute acid while preventing the structural collapse and active site degradation that inevitably occur during high-temperature standard drying.

Protecting Sensitive Active Sites

Mitigating Thermal Damage

Fe-N-C catalysts contain specific active sites that are highly sensitive to thermal stress.

Standard drying methods often require high temperatures to drive off liquid, which can induce structural thermal damage. By utilizing a vacuum, you lower the boiling point of the solvents, allowing for effective drying at temperatures that leave these critical active sites intact.

Efficient Solvent Removal

After the washing process, Fe-N-C powders retain residual solvents, particularly water and dilute hydrochloric acid.

A vacuum drying oven is essential for removing these completely. The negative pressure environment forces these trapped liquids to volatilize rapidly, ensuring the final powder is chemically pure and free of contaminants that could skew electrochemical performance.

Preserving Structural Integrity

Preventing Oxidative Agglomeration

One of the greatest risks during the drying phase is oxidative agglomeration.

When catalyst powders are exposed to heat in the presence of air (oxygen), the particles tend to clump together chemically. The vacuum environment removes oxygen from the equation, preventing this oxidation and ensuring the particles remain distinct and active.

Maintaining Porous Architecture

The performance of an Fe-N-C catalyst is heavily dependent on its porous structure.

High-temperature drying at standard pressure can cause capillaries to collapse or lead to "hard agglomeration." Vacuum drying preserves the loose, porous nature of the powder, ensuring that the high specific surface area required for catalysis is maintained.

Understanding the Trade-offs

Process Speed vs. Equipment Complexity

While vacuum drying is superior for quality, it introduces operational complexity compared to standard convection ovens.

You must manage vacuum pumps and ensure airtight seals, which adds a layer of maintenance. Additionally, while evaporation is efficient, the overall throughput per batch is often lower than in industrial belt dryers, making it a batch-process solution prioritized for quality over sheer volume.

Temperature Control Precision

Vacuum drying changes how heat transfers to the powder (conduction vs. convection).

You must be vigilant about the shelf temperature settings. Even under vacuum, setting the temperature too high can still cause localized overheating if the powder is stacked too thickly, negating the benefits of the low-pressure environment.

Making the Right Choice for Your Goal

To maximize the potential of your Fe-N-C catalyst, align your drying parameters with your specific material constraints.

- If your primary focus is Maximizing Electrochemical Activity: Prioritize the lowest possible temperature (e.g., 60°C) combined with high vacuum to protect the specific Fe-N coordination sites from thermal degradation.

- If your primary focus is Structural Morphology: Ensure the powder is spread thinly to prevent physical agglomeration, utilizing the vacuum to maintain the loose, high-surface-area pore structure.

Summary: The vacuum drying oven is not merely a drying tool; it is a preservation instrument that locks in the chemical and structural advantages engineered during the synthesis of Fe-N-C catalysts.

Summary Table:

| Feature | Standard Drying Oven | Laboratory Vacuum Drying Oven |

|---|---|---|

| Boiling Point | Higher (requires more heat) | Significantly Lower (lowers solvent boiling point) |

| Oxygen Presence | Atmospheric levels present | Negligible (prevents oxidative agglomeration) |

| Active Site Safety | High risk of thermal degradation | High protection of sensitive Fe-N coordination |

| Structural Impact | Risk of pore collapse/agglomeration | Preserves loose, high-surface-area architecture |

| Solvent Removal | Slower for stubborn solvents | Rapid and thorough volatilization |

Elevate Your Catalyst Performance with KINTEK

Don't let thermal stress or oxidation compromise your Fe-N-C research. KINTEK’s precision laboratory vacuum ovens are engineered to provide the stable, low-pressure environments necessary to preserve the delicate active sites and porous structures of your catalysts.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet the unique demands of your advanced materials processing. Ensure the chemical purity and structural integrity of your samples with a solution tailored to your lab.

Ready to optimize your drying process? Contact us today for a custom consultation!

Visual Guide

References

- Davide Menga, Michele Piana. On the Stability of an Atomically‐Dispersed Fe−N−C ORR Catalyst: An <i>In Situ</i> XAS Study in a PEMFC. DOI: 10.1002/celc.202400228

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why are high-purity alumina grinding balls used for Al2O3/TiC milling? Master Chemical Consistency

- What are the key advantages of using quartz tubes in high-temperature applications? Achieve Unmatched Thermal Stability and Purity

- Why is sample handling at high temperatures a risk for the alumina furnace tube? Prevent Thermal Shock Damage

- How does the temperature difference contribute to the cracking of the alumina furnace tube? Prevent Cracks for Longer Tube Life

- What role does a laboratory oven play in the evaluation of the physical properties of teak activated carbon? Accuracy Tips

- How does moisture in the heating material affect the alumina furnace tube? Prevent Catastrophic Tube Failure

- Why is laboratory heating equipment critical for photothermal actuators? Master Structural Curing & Precision Thermal Control

- What customization options are available for alumina ceramic tubes? Tailor for High-Temp, Corrosion-Resistant Applications