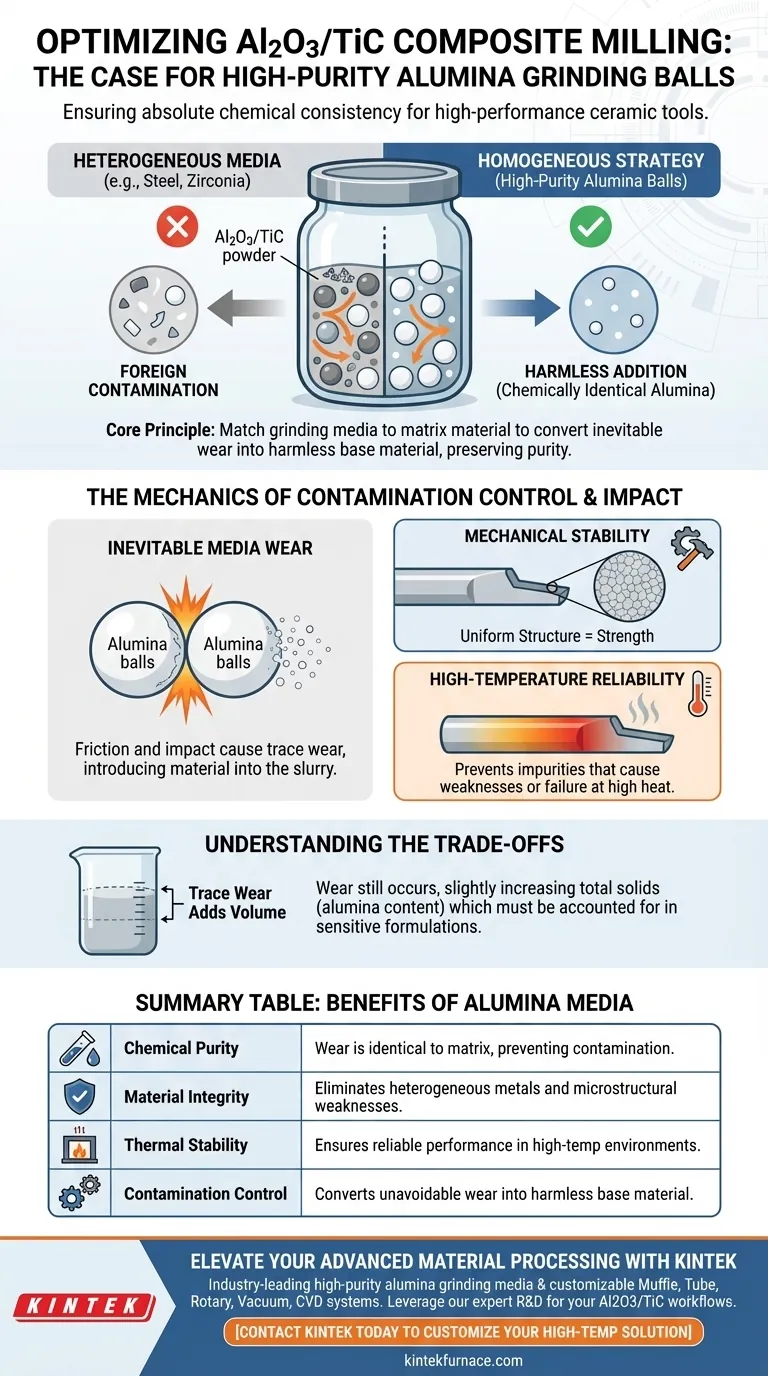

The selection of high-purity alumina grinding balls is dictated by the need for absolute chemical consistency. When wet ball milling Al2O3/TiC composite powders, the primary goal is to avoid introducing foreign contaminants. Because grinding media inevitably wears down during the milling process, using alumina balls ensures that any abraded material is chemically identical to the alumina matrix, effectively negating the impact of wear debris.

The core principle is simple: by matching the grinding media to the matrix material, you convert inevitable wear into harmless addition. This preserves the chemical purity necessary for the mechanical stability of ceramic tools in high-temperature environments.

The Mechanics of Contamination Control

The Inevitability of Media Wear

In any wet ball milling process, friction and impact are constant. The grinding balls grind the powder, but they also grind against each other and the mill walls.

Because of this, trace wear is unavoidable. The material from the grinding balls will eventually end up mixed into your slurry.

The Advantage of Homogeneous Materials

To manage this wear, you must utilize a homogeneous material strategy.

If you were to use steel or zirconia media, the wear debris would introduce "heterogeneous metals" or impurity elements into the mix.

By selecting high-purity alumina balls for an Al2O3 (alumina) matrix, the wear debris is no longer a contaminant; it is simply more of the base ingredient.

Impact on Final Product Performance

Ensuring Mechanical Stability

The Al2O3/TiC composites are often used to manufacture ceramic tool materials. These tools require exceptional mechanical properties to function correctly.

Introducing foreign impurities creates microstructural weaknesses. By maintaining chemical purity, you ensure the mechanical property stability of the final tool.

High-Temperature Reliability

These ceramic tools are designed for high-temperature applications.

Impurities that might be benign at room temperature can cause catastrophic failure or unpredictable chemical reactions under high heat.

Using high-purity alumina media eliminates the risk of introducing elements that could degrade performance in these thermal environments.

Understanding the Trade-offs

Wear Still Occurs

While the chemical composition remains pure, it is critical to remember that the physical grinding balls are still degrading.

Solids Loading Changes

Because the balls are wearing down, the total amount of solids in your slurry increases slightly over time.

While chemically consistent, this trace wear adds volume to the matrix phase. In extremely sensitive formulations, this additional alumina must be accounted for to maintain the precise ratio of Al2O3 to TiC.

Making the Right Choice for Your Goal

When processing Al2O3/TiC composites, your choice of media defines the ceiling of your material's performance.

- If your primary focus is Chemical Purity: Select high-purity alumina balls to ensure that media wear does not introduce heterogeneous impurities.

- If your primary focus is High-Temperature Performance: Prioritize media homogeneity to prevent foreign elements from compromising thermal stability.

Ultimately, choosing media that matches your matrix is the most effective way to safeguard the integrity of high-performance ceramic tools.

Summary Table:

| Feature | Benefit of Alumina Media in Al2O3/TiC Milling |

|---|---|

| Chemical Purity | Wear debris is chemically identical to the matrix, preventing contamination. |

| Material Integrity | Eliminates heterogeneous metals that cause microstructural weaknesses. |

| Thermal Stability | Ensures reliable performance of ceramic tools in high-temp environments. |

| Contamination Control | Converts inevitable media wear into harmless base material addition. |

Elevate Your Advanced Material Processing with KINTEK

Maintaining absolute chemical purity is critical for the performance of high-temperature ceramic tools. KINTEK provides industry-leading high-purity alumina grinding media alongside our comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems.

Backed by expert R&D and precision manufacturing, our lab equipment is fully customizable to meet the rigorous demands of Al2O3/TiC composite synthesis. Don't let media wear compromise your mechanical stability—leverage our expertise to optimize your milling and sintering workflows.

Contact KINTEK Today to Customize Your High-Temp Solution

Visual Guide

References

- Alejandro Padilla-González, I.A. Figueroa. Development and Mechanical Characterization of a CoCr-Based Multiple-Principal-Element Alloy. DOI: 10.1007/s13632-024-01111-z

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Magnesium Extraction and Purification Condensing Tube Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is the impact of gas flow meters on catalyst synthesis? Ensure Phase Purity and Precision in (NiZnMg)MoN Production

- Why is modified PTFE used as a liner in high-pressure reactors for MoS2/C? Enhancing Purity and Yield.

- Why is radiation correction necessary for K-type thermocouple readings? Ensure Accurate High-Temp Combustion Data

- What advantages do boron nitride (BN) crucibles offer for molten FUNaK salt? Ensure Purity & High-Temp Stability

- Why are high-purity alumina crucibles necessary for Li2Mg3Ti(1-x)ZrxO6 sintering? Ensure Dielectric Excellence

- Why is a molybdenum crucible considered an ideal choice for quartz melting? High-Purity Solutions at 2000°C

- What is the significance of using a laboratory electric thermostatic blast drying oven for biomass briquette moisture control?

- How does heating equipment with magnetic stirring contribute to Fe3O4 synthesis? Achieve Precise Nanoparticle Control