A molybdenum crucible is the definitive choice for quartz melting because it offers a critical balance of structural integrity and chemical inertness at extreme temperatures. It specifically withstands the 1900 to 2000 degrees Celsius range required for processing without deforming, ensuring the final product remains free of contamination.

Molybdenum serves as a "clean" thermal conductor, enabling the rapid melting of quartz sand while maintaining its high-purity state. Its ability to resist deformation at near-2000°C temperatures makes it a foundational component for high-precision manufacturing.

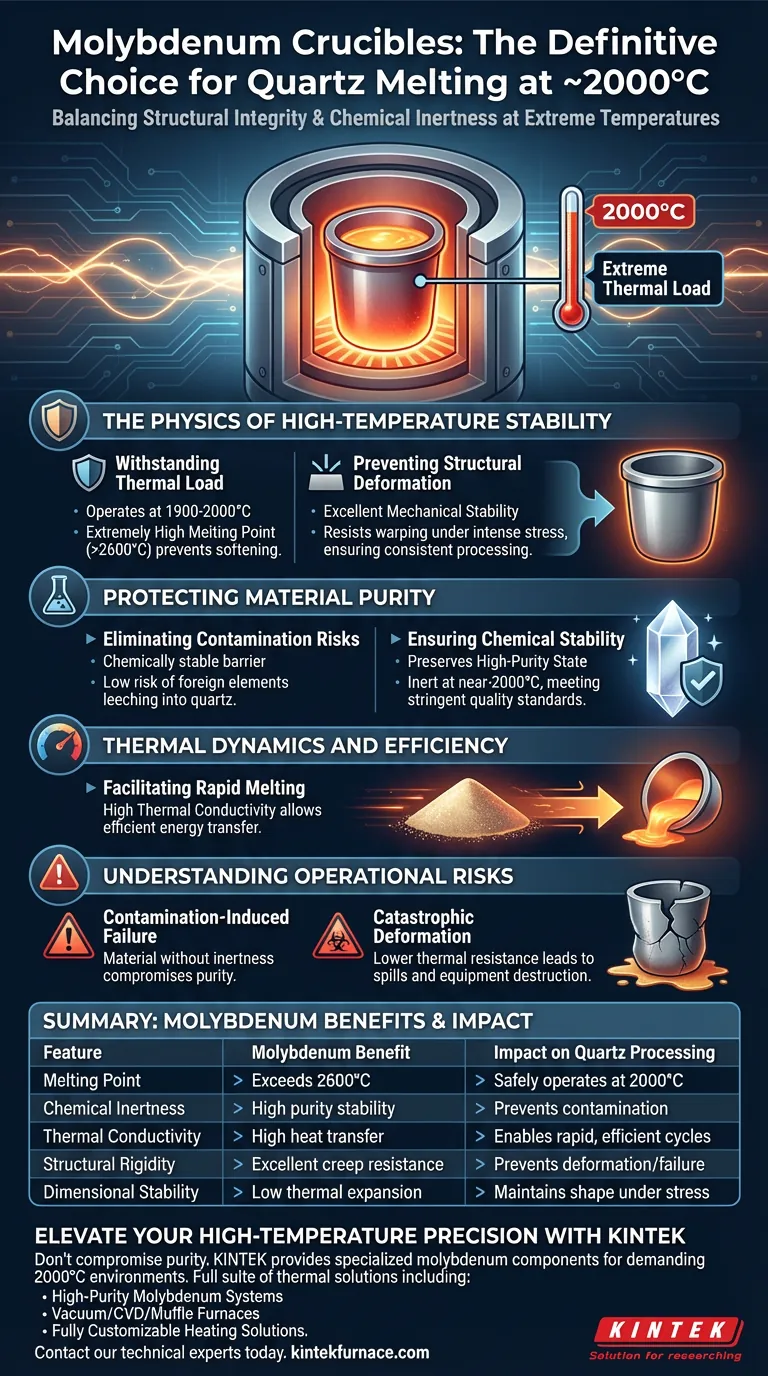

The Physics of High-Temperature Stability

Withstanding Extreme Thermal Load

Processing quartz requires an operating environment between 1900 and 2000 degrees Celsius. At these temperatures, many standard refractory materials would soften or collapse.

Molybdenum possesses an extremely high melting point that exceeds this processing window. This allows the crucible to maintain its shape and structural rigidity throughout the heating cycle.

Preventing Structural Deformation

Beyond just surviving the heat, the vessel must remain dimensionally stable. Molybdenum offers excellent mechanical stability, meaning it will not warp or deform under the intense thermal stress of the melt.

This stability is vital for ensuring consistent batch processing and protecting the furnace infrastructure from spills or failures caused by crucible collapse.

Protecting Material Purity

Eliminating Contamination Risks

In quartz processing, purity is the paramount metric. A crucible must not react with or release particles into the molten material.

Molybdenum is prized for its low risk of contaminating the melt. It provides a chemically stable barrier that prevents foreign elements from leeching into the quartz sand.

Ensuring Chemical Stability

The chemical stability of molybdenum ensures that the high-purity state of the quartz is preserved from start to finish.

Even at temperatures approaching 2000°C, the material remains inert relative to the quartz, ensuring the final output meets stringent quality standards.

Thermal Dynamics and Efficiency

Facilitating Rapid Melting

Efficiency in high-temperature processing is often dictated by how fast heat can be transferred. Molybdenum features high thermal conductivity.

This property allows for a rapid melting process, transferring energy efficiently from the heat source to the quartz sand. This speed helps optimize production cycles without sacrificing the quality of the melt.

Understanding the Operational Risks

The Consequence of Material Substitution

While molybdenum is ideal, it is important to understand the risks of using alternative materials in this specific temperature window.

The primary pitfall in quartz melting is contamination-induced failure. If a crucible material lacks molybdenum's specific chemical inertness, the purity of the entire quartz batch is compromised.

Furthermore, using materials with lower thermal resistance leads to catastrophic deformation. At 2000°C, the margin for error is non-existent; the vessel must be inherently capable of resisting these forces to avoid destroying both the product and the equipment.

Making the Right Choice for Your Goal

To ensure your high-temperature process yields the best results, evaluate your priorities against the capabilities of molybdenum:

- If your primary focus is Product Purity: Rely on molybdenum for its chemical stability to ensure no foreign contaminants alter the high-purity state of the quartz.

- If your primary focus is Process Safety and Stability: Utilize molybdenum to guarantee the crucible retains its shape and integrity without deformation at temperatures up to 2000°C.

By leveraging the thermal conductivity and extreme heat resistance of molybdenum, you ensure a process that is both rapid and reliable.

Summary Table:

| Feature | Molybdenum Benefit | Impact on Quartz Processing |

|---|---|---|

| Melting Point | Exceeds 2600°C | Safely operates at 2000°C without softening |

| Chemical Inertness | High purity stability | Prevents contamination of the quartz melt |

| Thermal Conductivity | High heat transfer | Enables rapid, efficient melting cycles |

| Structural Rigidity | Excellent creep resistance | Prevents deformation and catastrophic failure |

| Dimensional Stability | Low thermal expansion | Maintains shape under extreme thermal stress |

Elevate Your High-Temperature Precision with KINTEK

Don't compromise the purity of your quartz processing. KINTEK provides industry-leading high-temperature solutions, including specialized molybdenum components designed to withstand the most demanding 2000°C environments.

Backed by expert R&D and manufacturing, KINTEK offers a full suite of laboratory and industrial thermal solutions, including:

- High-Purity Molybdenum, Tube, and Rotary Systems

- Vacuum, CVD, and Muffle Furnaces

- Fully Customizable Heating Solutions tailored to your unique specifications.

Ensure your process remains stable, clean, and efficient. Contact our technical experts today to find the perfect thermal configuration for your laboratory or manufacturing needs.

Visual Guide

References

- Bartłomiej Adam Gaweł, Marisa Di Sabatino. Influence of aluminium doping on high purity quartz glass properties. DOI: 10.1039/d4ra01716a

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How does a heating stage contribute to the quality of multi-material 3D printing? Optimize Precision and Stability

- What are the advantages of using an infrared thermograph over traditional thermocouples in Plasma Flash Sintering (PFS)?

- How do industrial sealing clamps and O-ring systems ensure process repeatability? Achieve Consistent Sintering Quality

- Why are high-purity alumina crucibles used for LLZO sintering? Master Lithium Volatility Control

- How does a laboratory high-temperature oven facilitate the destabilization of lignin? Optimize Biomass Pretreatment

- Why are alumina crucibles used for CoNb2O6 synthesis? Ensure High-Purity Ceramic Powder Production

- How does an electromechanical vibrator assist in fuel feeding? Enhance Coal and Biomass Combustion Stability

- Why use high-performance insulation bricks in radiant tube simulations? Ensure precision and industrial accuracy.