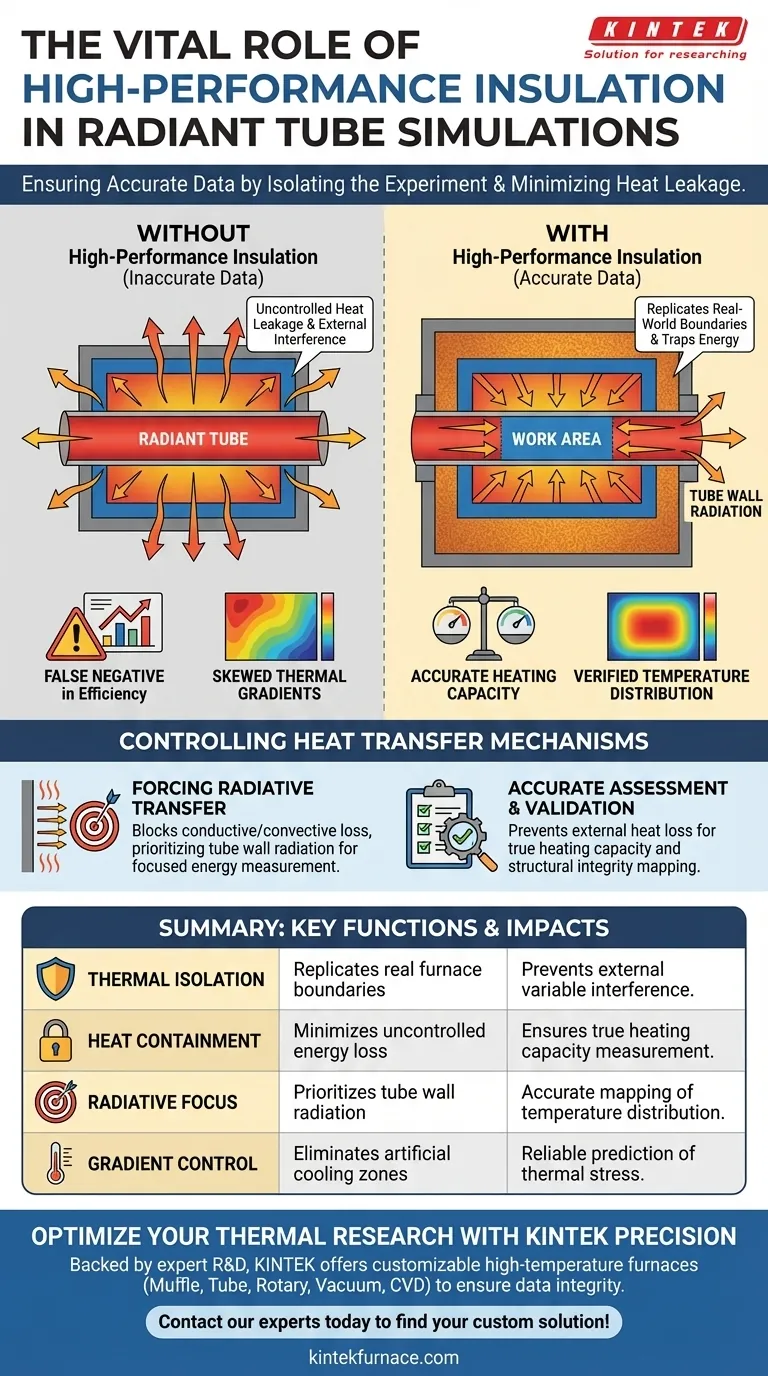

High-performance insulation bricks are essential for industrial radiant tube simulations because they are the primary mechanism for isolating the experiment from external variables. By providing high thermal resistance, these bricks minimize uncontrolled heat leakage, ensuring that the simulation data accurately reflects the tube's internal performance rather than the inefficiencies of the test environment.

The core function of these bricks is to replicate the thermal boundary conditions of a real industrial furnace. Without this insulation, heat escapes to the external environment rather than being directed to the work area, rendering measurements of heating capacity and temperature distribution invalid.

Replicating the Industrial Thermal Environment

Simulating Real-World Boundaries

An industrial furnace is a closed system designed to contain heat. To create a valid simulation model, you must replicate this specific thermal environment.

Using insulation bricks allows the test rig to mimic the containment properties of an actual production furnace. This ensures that the radiant tube interacts with its surroundings exactly as it would during operation.

Minimizing Uncontrolled Heat Loss

The primary technical challenge in thermal simulations is preventing energy from escaping to the laboratory environment.

High-performance insulation bricks offer significant thermal resistance. This barrier stops heat from bleeding out, effectively "trapping" the energy within the simulation boundary.

Controlling Heat Transfer Mechanisms

Forcing Radiative Transfer

The objective of these experiments is to analyze how the radiant tube transmits heat.

By blocking conductive and convective losses to the outside, insulation ensures that heat energy is transferred primarily via tube wall radiation. This forces the energy toward the intended work area, isolating the specific variable you are trying to measure.

Accurate Assessment of Heating Capacity

To determine the true power of a radiant tube, you must account for where the energy goes.

If heat is lost to the external environment, calculations regarding the tube's heating capacity will be skewed. Insulation ensures that the measured output is a result of the tube's efficiency, not a byproduct of a leaky test rig.

Verifying Surface Temperature Distribution

The temperature profile across the surface of the tube indicates its structural integrity and performance uniformity.

External cooling caused by poor insulation would alter this profile artificially. High-performance bricks maintain the correct ambient temperatures, allowing for an accurate mapping of the surface temperature distribution.

Understanding the Risks of Inadequate Insulation

The "False Negative" in Efficiency

If the insulation barrier is insufficient, the radiant tube will appear significantly less efficient than it actually is.

This creates a "false negative" in your data. You may incorrectly attribute energy loss to the tube design when, in reality, it is simply a failure of the experimental setup to contain the heat.

Skewed Thermal Gradients

Inadequate insulation creates uneven cooling zones around the experiment.

This leads to unpredictable thermal gradients. Data collected under these conditions cannot be reliably used to predict how the tube will withstand thermal stress in a real industrial application.

Ensuring Experimental Validity

To ensure your simulation yields actionable data, apply the following principles:

- If your primary focus is Validation: Ensure your insulation material has a thermal resistance rating comparable to the refractory materials used in the target industrial furnace.

- If your primary focus is Efficiency Analysis: Verify that external heat loss is negligible so that all measured energy transfer can be attributed to tube wall radiation.

Ultimately, the integrity of your simulation data depends entirely on your ability to contain the thermal environment.

Summary Table:

| Key Function | Benefit to Simulation | Impact on Data Accuracy |

|---|---|---|

| Thermal Isolation | Replicates real furnace boundaries | Prevents external variable interference |

| Heat Containment | Minimizes uncontrolled energy loss | Ensures true heating capacity measurement |

| Radiative Focus | Prioritizes tube wall radiation | Accurate mapping of temperature distribution |

| Gradient Control | Eliminates artificial cooling zones | Reliable prediction of thermal stress |

Optimize Your Thermal Research with KINTEK Precision

Ensure the integrity of your simulation data with high-performance thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of laboratory high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique experimental needs.

Don't let inadequate insulation skew your results. Partner with KINTEK to achieve superior temperature uniformity and energy efficiency in your lab.

Contact our experts today to find your custom solution!

Visual Guide

References

- Chien-Cheng Lin, Chien-Hsiung Tsai. Simulation of Staged Combustion Function in Double P-Type Radiant Tubes. DOI: 10.3390/engproc2025092094

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why are laboratory precision stirrers and heating devices essential for synthesizing magnetic precursor solutions?

- What are the secondary functions of high-purity graphite molds? Unlocking Advanced Sintering Capabilities

- What is the purpose of an ultrasonic cleaner in NiMo@Cx catalyst prep? Achieve Uniform Slurry & High-Porosity Coatings

- What cost factors should be considered when choosing an alumina ceramic furnace tube? Optimize Total Cost of Ownership

- Why are quartz tubes suitable for material research applications? Ensure Purity and Precision in High-Temp Experiments

- What functions do high-purity graphite crucibles serve in tantalum carbide synthesis? Essential Thermal & Chemical Roles

- What is the function of a precision oven in drying resin-impregnated wood? Optimize Your Bonding & Structural Integrity

- Why is a high-purity graphite crucible typically chosen for the high-temperature vacuum carbothermic reduction of magnesium oxide?