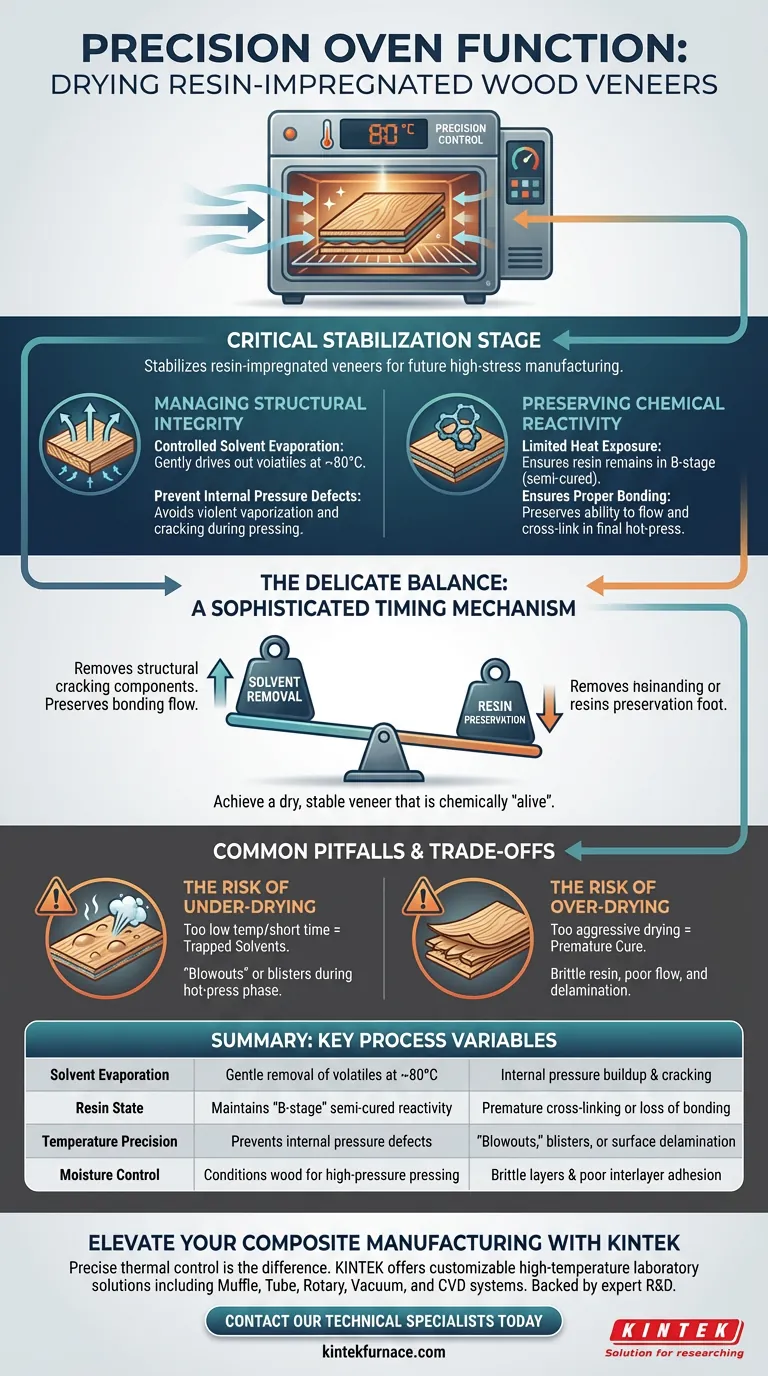

A precision temperature-controlled oven serves as the critical stabilization stage for resin-impregnated veneers. It functions primarily to evaporate solvents at a controlled rate to prevent internal pressure buildup, while strictly limiting heat exposure to ensure the resin does not cure before the final assembly.

The oven acts as a sophisticated timing mechanism: it removes volatile components that would cause structural cracking, yet it preserves the resin’s chemical ability to flow and bond during the future hot-pressing stage.

Managing Structural Integrity

The drying process is not simply about removing moisture; it is about conditioning the composite material for high-stress manufacturing.

Controlled Solvent Evaporation

Resin impregnation introduces solvents that must be removed before the wood undergoes high-pressure processing.

If these solvents remain trapped within the wood cells, they will vaporize violently during later heating stages. The oven maintains a steady, specific temperature (often around 80 °C) to gently drive these volatiles out.

Preventing Internal Pressure Defects

When solvents evaporate too quickly or are trapped during pressing, they create immense internal pressure.

This pressure is a primary cause of cracking in the wood structure. By regulating the drying rate, the oven ensures the veneer reaches a stable state without developing microscopic fractures or macroscopic splits.

Preserving Chemical Reactivity

The most delicate aspect of this process is managing the state of the resin itself.

Avoiding Premature Cross-Linking

Resins are designed to harden (cross-link) under heat, but this must happen only during the final hot-pressing stage.

If the drying oven is too hot, the resin will begin to cross-link prematurely. This "pre-cure" solidifies the resin inside the wood before the veneers are stacked or molded.

Ensuring Proper Bonding

For the final product to be durable, the resin must remain chemically reactive after it leaves the drying oven.

A precision oven ensures the resin remains in a "B-stage" or semi-cured state. This preserves its ability to flow, fill gaps, and form strong chemical bonds when the veneers are eventually pressed together.

Common Pitfalls and Trade-offs

Operating a drying oven involves navigating a narrow window of success between structural safety and chemical viability.

The Risk of Under-Drying

If you prioritize preserving the resin and set the temperature too low or the time too short, solvents will remain.

This leads to "blowouts" or blisters during the hot-press phase, as trapped steam and solvent gas explode outward, ruining the surface finish and internal bond.

The Risk of Over-Drying

Conversely, if you aggressively dry the wood to ensure all solvents are gone, you risk advancing the resin too far.

Over-dried veneers contain brittle, fully cured resin that will not fuse with adjacent layers. This results in delamination, where the layers of the final product peel apart under stress.

Making the Right Choice for Your Goal

To optimize your drying process, you must balance solvent removal against resin preservation.

- If your primary focus is preventing surface cracks: Ensure the oven temperature is high enough to fully evaporate solvents (e.g., 80 °C) to eliminate internal pressure during pressing.

- If your primary focus is ultimate bond strength: Strictly monitor thermal exposure time to ensure the resin retains enough reactivity to flow and cross-link during the final hot-press.

Success lies in achieving a veneer that is dry enough to remain stable, yet chemically "alive" enough to bond.

Summary Table:

| Process Variable | Role in Drying | Impact of Poor Control |

|---|---|---|

| Solvent Evaporation | Gentle removal of volatiles at ~80°C | Internal pressure buildup and structural cracking |

| Resin State | Maintains "B-stage" semi-cured reactivity | Premature cross-linking or loss of bonding flow |

| Temperature Precision | Prevents internal pressure defects | "Blowouts," blisters, or surface delamination |

| Moisture Control | Conditions wood for high-pressure pressing | Brittle layers and poor interlayer adhesion |

Elevate Your Composite Manufacturing with KINTEK

Precise thermal control is the difference between a high-strength bond and a total material failure. At KINTEK, we understand the delicate balance required for drying resin-impregnated materials. Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of laboratory high-temperature solutions—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all of which are fully customizable to meet your specific resin-drying and heat-treatment needs.

Ensure your veneers remain chemically active and structurally sound with equipment engineered for precision. Contact our technical specialists today to discuss your project requirements and discover how our advanced furnace technology can optimize your production outcomes.

Visual Guide

References

- Johannes Karthäuser, Holger Militz. Modification of plywood with phenol–formaldehyde resin: substitution of phenol by pyrolysis cleavage products of softwood kraft lignin. DOI: 10.1007/s00107-023-02029-z

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- Why use a fusion furnace and platinum crucibles for XRF analysis of magnesium slag? Ensure Accurate Results

- Why is a high-purity graphite crucible preferred for (AgCu)0.999Te0.69Se0.3S0.01 preparation? Ensure Peak Purity.

- What are the benefits of the improved circulating water vacuum pump? Save Costs and Go Green in Your Lab

- What are the main composition percentages of alumina tubes? Optimize Performance for High-Temperature Applications

- What are the main reasons for the alumina furnace tube being prone to breaking? Prevent Costly Failures with Expert Tips

- What is the function of a high-precision mass flow controller (MFC) in CdS nanobelt vapor deposition?

- Why is it necessary to use a high-vacuum pump system for sodium heat pipes? Achieving $10^{-6}$ Pa for Peak Efficiency

- What are the technical advantages of using high-purity quartz tubes? Optimize Heat and Purity in Combustion Analysis