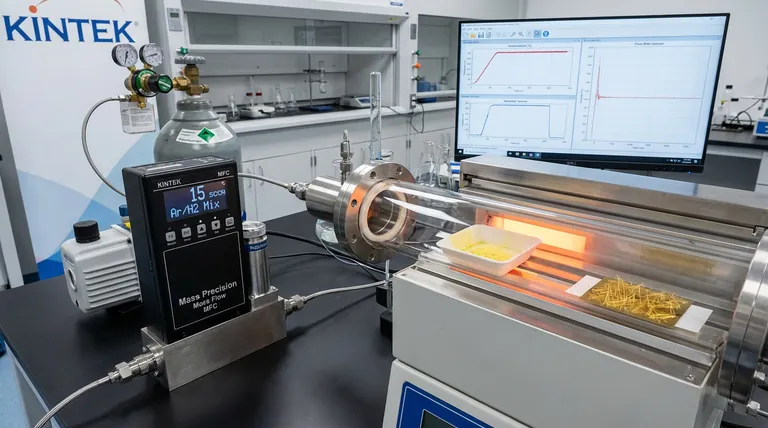

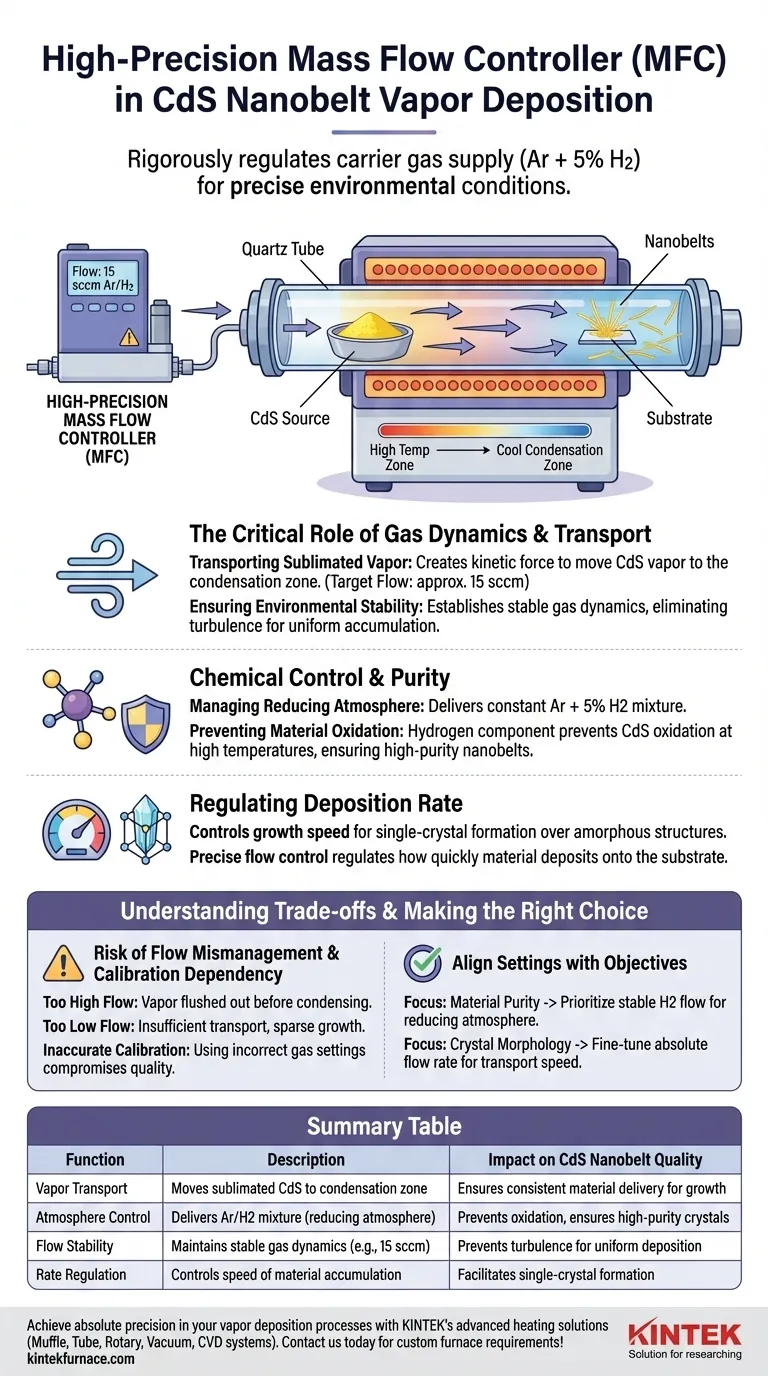

The primary function of a high-precision mass flow controller (MFC) in this setup is to rigorously regulate the supply of carrier gas to the tube furnace. Specifically, it controls the flow rate of a gas mixture—typically argon with 5% hydrogen—to ensuring the precise environmental conditions required for the vapor deposition process.

By establishing a stable gas dynamic environment, the MFC guarantees the consistent transport of sublimated vapor and maintains a reducing atmosphere, which is essential for growing high-quality, single-crystal CdS nanobelts.

The Critical Role of Gas Dynamics

Transporting Sublimated Vapor

The fundamental physical task of the MFC is to manage the movement of the carrier gas.

In this specific application, the controller often maintains a flow rate around 15 sccm (standard cubic centimeters per minute).

This flow creates the kinetic force necessary to transport sublimated CdS vapor from the source material to the cooler condensation zone where growth occurs.

Ensuring Environmental Stability

Vapor deposition is highly sensitive to turbulence or stagnation.

A high-precision MFC creates a stable gas dynamic environment within the furnace tube.

This stability eliminates fluctuations that could disrupt the uniform accumulation of material on the substrate.

Chemical Control and Purity

Managing the Reducing Atmosphere

The process utilizes a specific gas mixture, such as argon combined with 5% hydrogen.

The MFC ensures that the ratio and total volume of this mixture remain constant throughout the deposition cycle.

Preventing Material Oxidation

The hydrogen component in the gas stream acts as a reducing agent.

By precisely delivering this hydrogen, the MFC prevents the oxidation of the CdS material at high temperatures.

This protection is a vital guarantee for obtaining high-purity nanobelts rather than oxidized byproducts.

Regulating the Deposition Rate

The flow rate is not just a transport mechanism; it is a control variable for growth speed.

The hydrogen component helps regulate how quickly the material deposits onto the substrate.

Precise control here allows for the formation of single-crystal structures rather than amorphous or poly-crystalline films.

Understanding the Trade-offs

The Risk of Flow Mismanagement

While high precision is the goal, an incorrect flow setting can be detrimental.

If the flow is too high, the vapor may be flushed out of the tube before it can condense properly.

If the flow is too low, the vapor transport may be insufficient, leading to sparse or uneven growth.

Calibration Dependency

The "high precision" of an MFC is only as good as its calibration.

Reling heavily on an MFC assumes the device is accurately calibrated for the specific gas mixture (Ar/H2) being used.

Using a controller calibrated for Nitrogen or pure Argon without adjustment factors will result in inaccurate flow rates and compromised crystal quality.

Making the Right Choice for Your Goal

To maximize the quality of your CdS nanobelts, align your MFC settings with your specific objectives:

- If your primary focus is Material Purity: Prioritize the stability of the hydrogen mixture flow to maintain a constant reducing atmosphere and prevent oxidation.

- If your primary focus is Crystal Morphology: Fine-tune the absolute flow rate (e.g., sticking strictly to 15 sccm) to control the vapor transport speed and deposition kinetics.

Ultimate control over your gas flow is the defining factor in transitioning from basic material synthesis to high-quality single-crystal engineering.

Summary Table:

| Function | Description | Impact on CdS Nanobelt Quality |

|---|---|---|

| Vapor Transport | Moves sublimated CdS to the condensation zone | Ensures consistent material delivery for growth |

| Atmosphere Control | Delivers Ar/H2 mixture (reducing atmosphere) | Prevents oxidation and ensures high-purity crystals |

| Flow Stability | Maintains stable gas dynamics (e.g., 15 sccm) | Prevents turbulence to allow uniform deposition |

| Rate Regulation | Controls the speed of material accumulation | Facilitates single-crystal formation over amorphous structures |

Achieve absolute precision in your vapor deposition processes with KINTEK's advanced heating solutions. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to your unique research needs. Whether you are synthesizing high-purity nanobelts or complex semiconductor materials, our high-precision systems provide the stability and control required for consistent, high-quality results. Contact us today to discuss your custom furnace requirements with our technical team!

Visual Guide

References

- Yao Liu, Yingkai Liu. High-response formamidine bromide lead hybrid cadmium sulfide photodetector. DOI: 10.3788/col202422.022502

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Ultra-High Vacuum Flange Aviation Plug Glass Sintered Airtight Circular Connector for KF ISO CF

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- Why are high-alumina crucibles required for static immersion corrosion tests? Ensure Data Purity at 1000°C

- Why is vacuum sealing in high-purity quartz tubes necessary for the synthesis of FexTaSe2? Master Crystal Growth

- What is the role of a vacuum pass-box and a high-capacity vacuum pump? Ensuring Safety in Battery Recycling

- What is the purpose of a PTFE-lined autoclave in TiO2 synthesis? Unlock Precision Nano-material Growth

- Why is a quartz tube selected as the sample container for emissivity measurement? Precision Microwave Heating Benefits

- What is the function of the nitrogen environment in pyrolysis? Mastering Carbonization with Laboratory Furnaces

- What role does a ceramic crucible play in oxidation weight gain experiments for Ti-V-Cr alloys? Ensure Data Accuracy

- Why is a laboratory oven utilized during the pre-treatment stage of chicken bone waste pyrolysis?