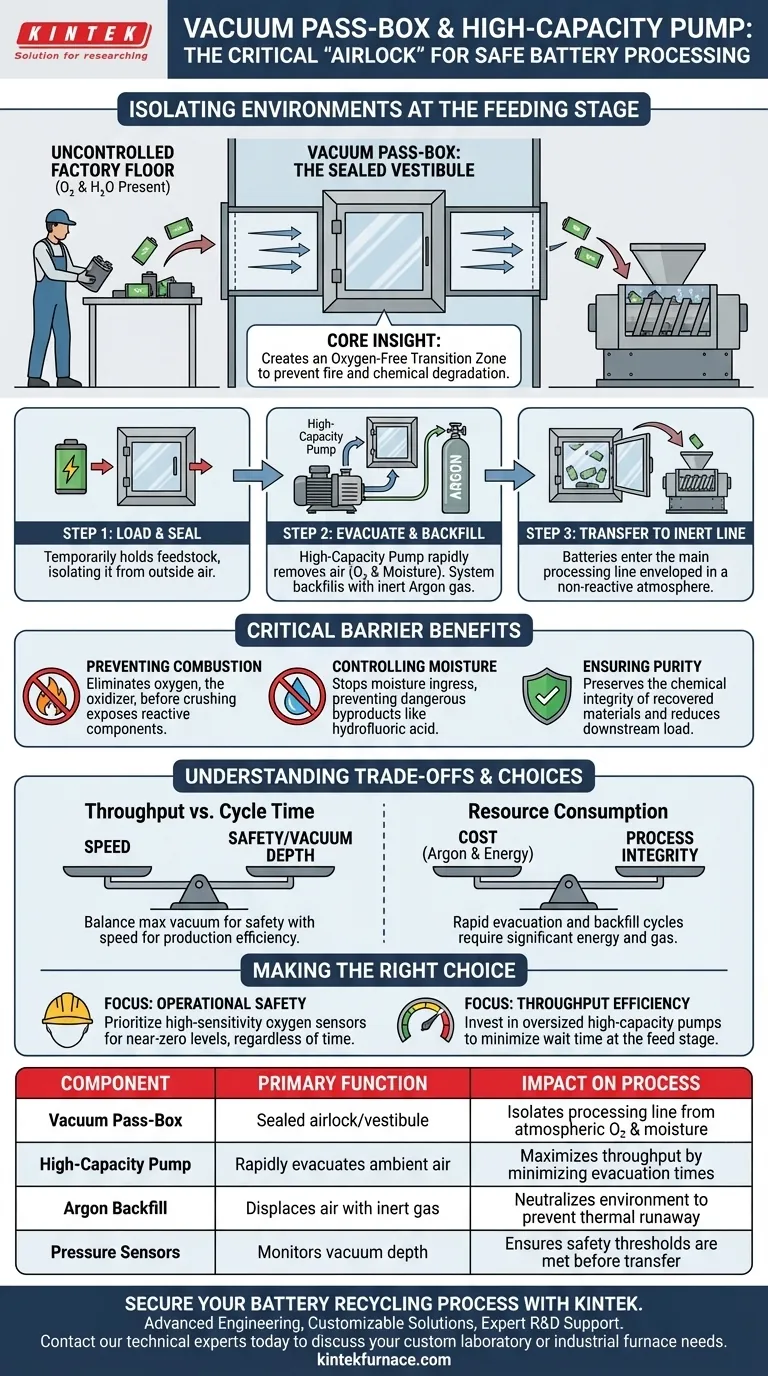

In the context of spent lithium-ion battery processing, a vacuum pass-box and a high-capacity vacuum pump function as a critical "airlock" system at the feeding stage. Together, they mechanically isolate the external environment from the internal processing line, ensuring that materials are transferred without introducing atmospheric contaminants.

Core Insight By establishing an oxygen-free transition zone, this system mitigates the risk of fire and chemical degradation. It evacuates ambient air and backfills the chamber with inert gas, preserving the integrity of the controlled atmosphere required for safe crushing and drying.

Creating the Oxygen-Free Transition Zone

The Mechanism of the Vacuum Pass-Box

The vacuum pass-box serves as a sealed vestibule between the uncontrolled factory floor and the sensitive internal processing chamber.

Its primary role is to hold the battery feedstock temporarily while the atmosphere around the batteries is manipulated.

This prevents the direct opening of the main chamber to the outside air, which would immediately compromise the facility's inert environment.

The Role of the High-Capacity Vacuum Pump

The high-capacity vacuum pump acts as the engine of this transition zone, rapidly evacuating ambient air from the pass-box once it is loaded and sealed.

Using a high-capacity pump is essential to achieve a deep vacuum quickly, maintaining high processing throughput without creating a bottleneck at the feed point.

This rapid evacuation removes oxygen and ambient moisture that are naturally present in the air surrounding the batteries.

The Argon Backfill Process

Once the air is evacuated, the system backfills the pass-box with high-purity argon gas.

Because argon is inert, it neutralizes the environment surrounding the spent batteries before the inner door opens to the main processing line.

This step ensures that when the material finally enters the crushing stage, it is enveloped in a stable, non-reactive atmosphere.

Why This Barrier is Critical

Preventing Combustion Events

The crushing stage of battery recycling exposes highly reactive internal components, including lithium metal and flammable electrolytes.

If oxygen were allowed to enter through the feeding stage, the mechanical energy of crushing could trigger immediate thermal runaway or combustion.

The vacuum pass-box eliminates the oxidizer (oxygen) from the equation, rendering the crushing process significantly safer.

Controlling Moisture Ingress

Lithium-ion battery chemistries are extremely sensitive to moisture, which can lead to the formation of dangerous byproducts like hydrofluoric acid.

The primary reference notes that the pass-box acts as a specific barrier to prevent moisture from reaching the subsequent drying stages.

By stopping moisture at the entry point, the system reduces the load on downstream drying equipment and preserves the chemical value of the recovered materials.

Understanding the Trade-offs

Throughput vs. Cycle Time

A vacuum pass-box introduces a pulsed, batch-like stop in what might otherwise be a continuous process.

The time required to pull a vacuum and backfill with argon creates a constraint on how fast batteries can be fed into the system.

Operators must balance the need for a deep vacuum (maximum safety) with the need for speed (production efficiency).

Resource Consumption

The "evacuate and backfill" cycle consumes significant quantities of argon gas, which is an operational cost.

Furthermore, the high-capacity pumps require substantial energy to rapidly depressurize the chamber repeatedly.

Leaks or poor seal integrity in the pass-box can lead to skyrocketing gas costs and compromised safety margins.

Making the Right Choice for Your Goal

To ensure your processing line remains safe and efficient, consider the following:

- If your primary focus is Operational Safety: Prioritize high-sensitivity sensors within the pass-box to verify Oxygen levels are near zero before the inner gate opens, regardless of cycle time.

- If your primary focus is Throughput Efficiency: Invest in oversized high-capacity pumps to reduce the time required to reach the target vacuum level, minimizing the "wait time" at the feed stage.

The vacuum pass-box is not just a door; it is the primary gatekeeper that dictates the safety and chemical purity of your entire recycling operation.

Summary Table:

| Component | Primary Function | Impact on Process |

|---|---|---|

| Vacuum Pass-Box | Acts as a sealed airlock/vestibule | Isolates processing line from atmospheric oxygen and moisture |

| High-Capacity Pump | Rapidly evacuates ambient air | Maximizes throughput by minimizing evacuation cycle times |

| Argon Backfill | Displaces air with inert gas | Neutralizes the environment to prevent thermal runaway during crushing |

| Pressure Sensors | Monitors vacuum depth | Ensures safety thresholds are met before material transfer |

Secure Your Battery Recycling Process with KINTEK

Transitioning to large-scale lithium-ion battery processing requires uncompromising safety and precision. KINTEK provides the specialized equipment needed to manage reactive environments effectively.

Our value to you:

- Advanced Engineering: Our Vacuum and CVD systems are designed to integrate seamlessly into inert-gas processing lines.

- Customizable Solutions: We offer custom Muffle, Tube, and Rotary high-temp furnaces tailored to your unique throughput and safety requirements.

- Expert R&D Support: Benefit from our extensive manufacturing experience in lithium-ion recovery and material science.

Ready to optimize your feeding stage and eliminate combustion risks? Contact our technical experts today to discuss your custom laboratory or industrial furnace needs.

Visual Guide

References

- Sung-Hoon Jung, Jei‐Pil Wang. Development of a discharge-free pre-treatment device for spent lithium-ion batteries under an inert atmosphere. DOI: 10.53894/ijirss.v8i9.10684

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

People Also Ask

- Why is the use of high-alumina crucibles essential for NCM811? Ensure Purity in High-Nickel Cathode Synthesis

- How do alumina ceramic tubes compare to quartz ceramic tubes in terms of thermal properties? Choose the Right Tube for High-Temp Success

- What are the common types and size ranges of Alumina ceramic tubing? Find the Perfect Fit for Your Lab

- What role does an alumina crucible play during the gas nitriding process for stainless steel? Ensure Surface Purity

- How does a precision programmed cooling system influence the structural integrity of Al2O3-TiC composite materials?

- Why is a quartz boat considered an essential carrier tool for the catalytic pyrolysis synthesis of carbon nanotubes?

- What role does a precision drying oven play in the pre-treatment of Bi-Fe oxide powders? Safeguard Your Nano-Morphology

- How does a Mass Flow Controller (MFC) regulate TCNF morphology? Achieve Precise Carbon Nanofiber Growth