When selecting a ceramic tube for high-temperature applications, the thermal properties of alumina and quartz dictate their ideal use cases. Alumina ceramic tubes are defined by their superior thermal conductivity and exceptional thermal shock resistance, making them durable in dynamic temperature environments. Quartz tubes, while also thermally stable, are primarily valued for their extreme purity, which is critical in processes where contamination must be avoided at all costs.

Your choice between alumina and quartz is not about which material is "better," but which specific thermal characteristic is most critical for your application's success. Alumina offers resilience to thermal stress, while quartz provides unparalleled purity and stability.

A Tale of Two Materials: Thermal Property Breakdown

Understanding the core thermal differences between alumina and quartz is the first step in making an informed decision. Each material's unique atomic structure gives rise to distinct behaviors under heat.

Alumina: The Resilient Workhorse

Alumina (Aluminum Oxide, Al₂O₃) is known for its robustness. Its key thermal properties are high thermal conductivity and low thermal expansion.

High thermal conductivity means heat spreads quickly and evenly throughout the tube. This prevents "hot spots" from forming, which are a common cause of stress and failure.

Simultaneously, its low thermal expansion means the tube does not significantly change its size or shape when heated. The combination of these two factors gives alumina its standout feature: superior thermal shock resistance. It can withstand rapid heating and cooling cycles without cracking.

Furthermore, high-purity alumina tubes can operate at extremely high temperatures, with some grades rated for use up to 1800°C.

Quartz: The High-Purity Specialist

Quartz (Silicon Dioxide, SiO₂) is defined by its exceptional purity and stability. High-purity quartz tubes can reach 99.99% purity, significantly higher than the 99.5%-99.8% purity of typical high-grade alumina.

While alumina is tougher, quartz offers excellent thermal stability, meaning its properties remain consistent and predictable across a wide temperature range. This is particularly important in high-precision applications.

This stability, combined with the ability to manufacture tubes with excellent tolerances, makes quartz ideal for processes where dimensional consistency during heating is paramount.

Practical Implications in Your Application

These properties directly translate into performance advantages and disadvantages depending on the working environment.

Why Alumina Excels in Dynamic Thermal Environments

Alumina is the default choice for applications involving aggressive temperature changes. Its ability to resist thermal shock makes it perfect for furnaces that are frequently cycled on and off.

Its mechanical strength and wear resistance add to this durability, extending the component's service life in demanding industrial settings like metallurgy and chemical processing.

Critically, alumina ceramics are also gas-tight. This allows them to maintain a strong vacuum or a pure, protective atmosphere at very high temperatures, which is essential for consistent and repeatable thermal processing.

When to Prioritize Quartz for Purity and Precision

Quartz is the clear winner in applications where even trace amounts of contamination can ruin a process. The primary example is semiconductor manufacturing, where the 99.99% purity of quartz is non-negotiable.

The material's extreme purity ensures that nothing leaches from the tube into the high-purity chemicals or gases being processed, even at elevated temperatures.

Its dimensional stability and tight manufacturing tolerances also make it suitable for laboratory and optical systems where precision is the highest priority.

Understanding the Trade-offs

No material is perfect. The choice between alumina and quartz involves a direct trade-off between durability and purity.

The Purity vs. Durability Compromise

Alumina is mechanically tougher and far more resistant to thermal shock. If your process involves rapid temperature changes, physical stress, or abrasion, alumina is the safer choice.

Quartz, while thermally stable, is more brittle and generally less resistant to sudden, extreme temperature swings compared to alumina. Its primary advantage is its unmatched purity, which comes at the cost of mechanical ruggedness.

Processing and Handling

The materials also require different considerations for use. Alumina's robust nature makes it more forgiving in an industrial setting.

However, certain high-purity alumina components may require specialized procedures, such as ultrasonic cleaning, to ensure they are prepared for sensitive applications. Quartz, being more brittle, requires careful handling to prevent chipping or cracking.

Making the Right Choice for Your Process

Base your decision on the single most critical requirement of your application.

- If your primary focus is rapid heating/cooling cycles or maximum durability: Choose alumina for its superior thermal shock resistance and high thermal conductivity.

- If your primary focus is preventing material contamination in a sensitive process: Choose quartz for its exceptional 99.99% purity and thermal stability.

- If your primary focus is maintaining a stable, gas-tight environment at very high temperatures (up to 1800°C): Alumina is the proven choice for creating a reliable vacuum or protective atmosphere.

Understanding these core thermal differences empowers you to select the material that ensures the integrity and success of your high-temperature application.

Summary Table:

| Property | Alumina Ceramic Tubes | Quartz Ceramic Tubes |

|---|---|---|

| Thermal Conductivity | High | Moderate |

| Thermal Shock Resistance | Superior | Lower |

| Maximum Temperature | Up to 1800°C | Varies, generally lower |

| Purity | Up to 99.8% | Up to 99.99% |

| Key Advantage | Durability in dynamic thermal environments | Extreme purity and dimensional stability |

| Ideal Applications | Metallurgy, chemical processing, vacuum atmospheres | Semiconductor manufacturing, high-precision labs |

Struggling to choose the right ceramic tube for your high-temperature needs? KINTEK is here to help! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you need the thermal shock resistance of alumina or the purity of quartz, we'll deliver the perfect solution to enhance your process efficiency and reliability. Contact us today for expert guidance and tailored support!

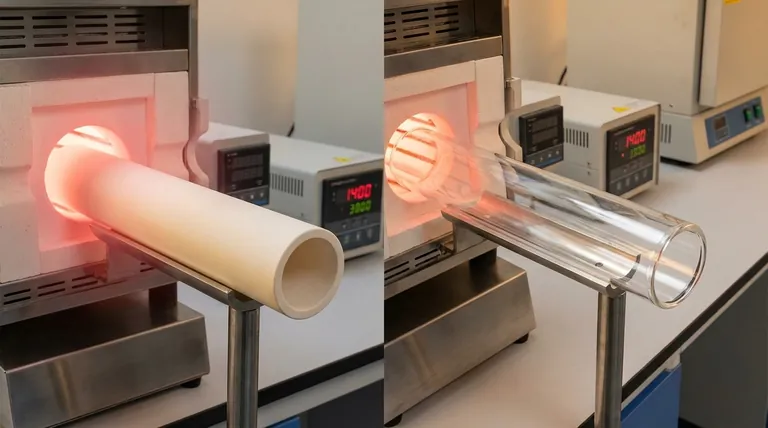

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is flash vacuum pyrolysis and how is a tube furnace utilized in this process? Unlock High-Temp Chemical Reactions

- How does a tube heating furnace facilitate the carbon coating process? Boost Layered Oxide Conductivity

- What core process conditions does a tube furnace provide? Mastering Catalyst Precursor Treatment

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What function does a tube furnace serve in the PVT growth of J-aggregate molecular crystals? Mastery of Thermal Control