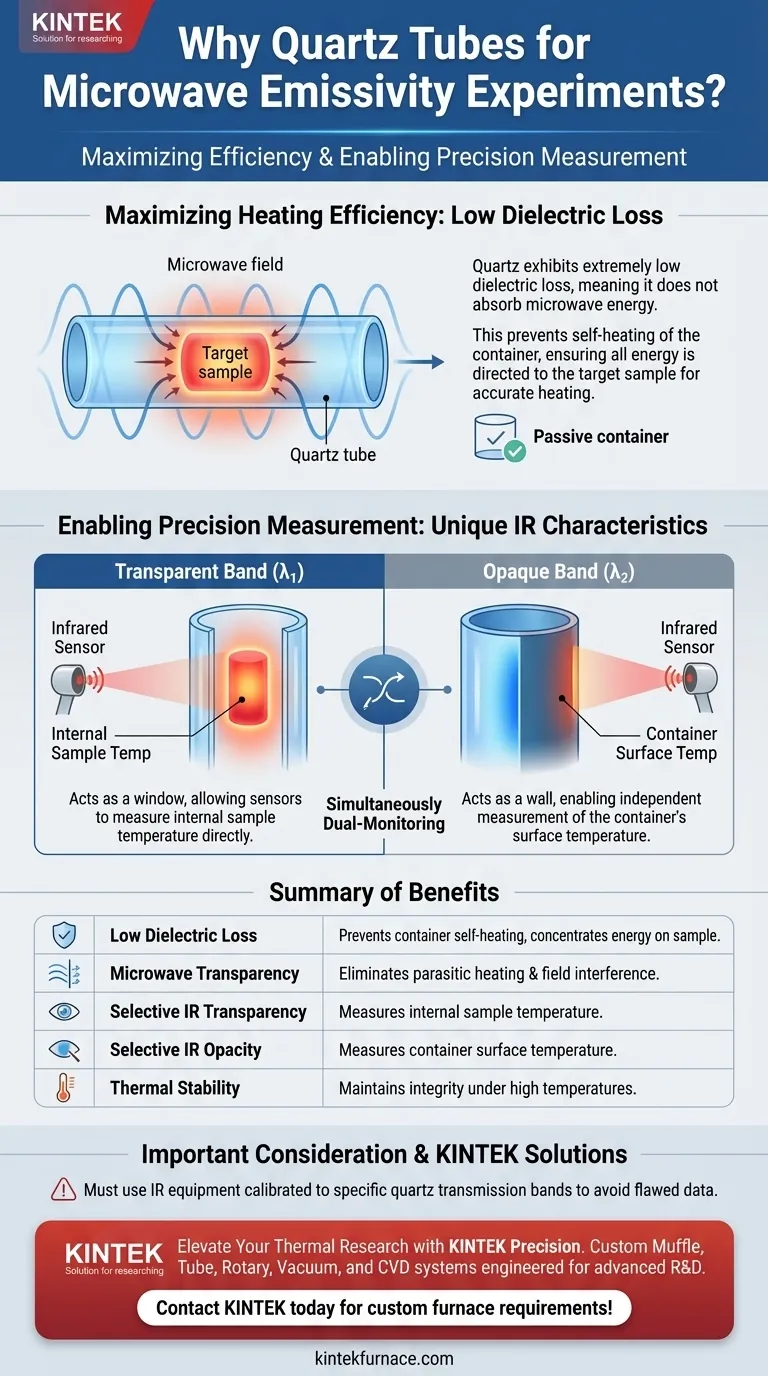

Quartz tubes are selected as the primary containment vessel for microwave emissivity experiments due to their extremely low dielectric loss. This physical property ensures the container does not absorb microwave energy, preventing it from interfering with the heating process of the target sample. Additionally, quartz possesses unique optical characteristics that facilitate complex, simultaneous temperature measurements.

In microwave heating experiments, the container must be a passive participant. Quartz achieves this by remaining inert to the microwave field while acting as a selective optical filter, allowing researchers to independently monitor both the sample’s internal heat and the container’s surface temperature.

Maximizing Heating Efficiency

The Role of Low Dielectric Loss

To accurately measure emissivity during microwave heating, the energy must be concentrated solely on the sample material.

Quartz exhibits extremely low loss in a microwave field. This means the material does not interact significantly with the electromagnetic waves.

Because the tube does not absorb energy, it does not self-heat. This ensures that any rise in temperature is driven by the sample, not the container.

Enabling Precision Measurement

Unique Infrared Characteristics

Beyond its microwave transparency, quartz offers a distinct advantage in how it handles infrared (IR) light.

It displays specific transparency and opacity characteristics depending on the infrared band. It acts as a window for some wavelengths and a wall for others.

Simultaneous Dual-Monitoring

This selective optical behavior solves a major challenge in thermal monitoring.

By utilizing infrared temperature measurement equipment operating at different wavelengths, researchers can exploit these bands.

One sensor can look "through" the transparent bands of the quartz to measure the internal sample temperature directly.

Simultaneously, a different sensor operating in an opaque band can measure the container surface temperature. This allows for the independent tracking of two critical thermal data points at the exact same time.

Understanding the Trade-offs

Equipment Compatibility

While quartz offers superior performance, it introduces complexity regarding instrumentation.

You cannot use a generic infrared thermometer. To leverage the dual-monitoring capability, your measurement equipment must be calibrated to the specific transmission and opacity bands of the quartz.

Using an incompatible sensor wavelength could lead to reading the wrong surface (e.g., reading the glass temperature when you intend to read the sample), resulting in flawed data.

Making the Right Choice for Your Experiment

To ensure your experimental setup yields valid emissivity data, consider your specific measurement goals:

- If your primary focus is heating efficiency: Rely on quartz to eliminate parasitic heating, ensuring all microwave energy is directed solely at your target material.

- If your primary focus is thermal profiling: Ensure your infrared sensors are matched to the specific transmission bands of the quartz to accurately separate sample temperature from container temperature.

Quartz transforms the sample container from a simple vessel into an active component of your measurement instrumentation.

Summary Table:

| Feature | Benefit for Emissivity Measurement |

|---|---|

| Low Dielectric Loss | Prevents container self-heating; ensures energy is concentrated on the sample. |

| Microwave Transparency | Eliminates parasitic heating and interference with the electromagnetic field. |

| Selective IR Transparency | Allows IR sensors to look through the tube to measure internal sample temperature. |

| Selective IR Opacity | Enables simultaneous measurement of the container's surface temperature. |

| Thermal Stability | Maintains structural integrity under high-temperature microwave conditions. |

Elevate Your Thermal Research with KINTEK Precision

Don't let subpar containment compromise your data. KINTEK provides high-performance, customizable lab solutions including Muffle, Tube, Rotary, Vacuum, and CVD systems—all engineered to meet the rigorous demands of advanced R&D. Whether you are optimizing microwave heating efficiency or requiring specialized high-temperature furnaces, our expert manufacturing team is ready to tailor a solution to your unique experimental needs.

Contact KINTEK today to discuss your custom furnace requirements!

Visual Guide

References

- Gloria Cosoli, Gian Marco Revel. A Measurement Approach for Characterizing Temperature-Related Emissivity Variability in High-Emissivity Materials. DOI: 10.3390/s25020487

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What role does a high-temperature ceramic crucible play in the pyrolysis synthesis of biochar? Ensure Pure Lab Results

- What function does a planetary ball mill perform in LiFePO4/C synthesis? Optimize Battery Material Conductivity

- Why are Type K thermocouples preferred in industrial furnaces? Unlock Reliable Precision for High-Heat Control

- Why are magnesium oxide-stabilized zirconia crucibles used for melting alloys? High-Temp Stability up to 1900°C

- What role does a laboratory vacuum pump play in a static batch desulfurization evaluation system? Ensure Data Integrity

- What roles do high-purity graphite molds perform in A357 sintering? Enhancing Aluminum Matrix Composite Performance

- Why is a quartz boat considered an essential carrier tool for the catalytic pyrolysis synthesis of carbon nanotubes?

- What is the primary purpose of a benchtop blast drying oven? Optimize Barium Titanate Ceramic Preparation