In the context of carbothermal reduction synthesis, the planetary ball mill functions as a high-energy mechanical reactor designed to achieve deep, uniform mixing of iron phosphate dihydrate, lithium carbonate, and glucose. By operating at specific high speeds, such as 300 rpm, the mill subjects these precursors to intense grinding forces. This process reduces particle size to the nanoscale, ensuring the carbon source is intimately mixed with the active materials before the thermal reaction occurs.

The planetary ball mill is not merely a mixer; it is a critical pre-treatment tool that facilitates nanoscale dispersion and uniform carbon coating, directly enabling the enhanced electrochemical conductivity required for high-performance batteries.

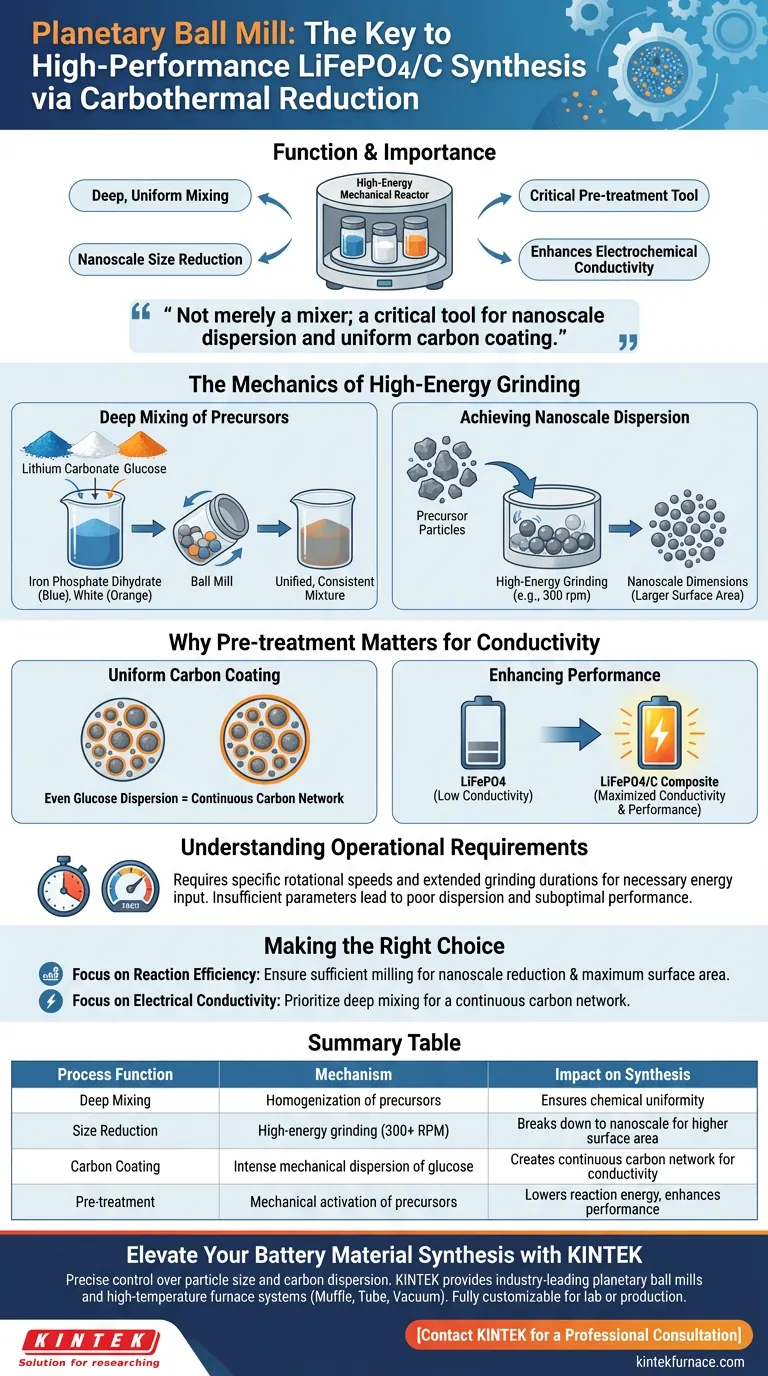

The Mechanics of High-Energy Grinding

Deep Mixing of Precursors

The primary function of the planetary ball mill is to homogenize the raw materials: iron phosphate dihydrate, lithium carbonate, and glucose.

Standard mixing methods often fail to achieve the intimacy required for efficient chemical reactions in solid-state synthesis.

The ball mill overcomes this by forcing these distinct compounds into a unified, consistent mixture.

Achieving Nanoscale Dispersion

The mill utilizes high-energy grinding to physically break down the precursor particles.

By operating at optimized speeds (e.g., 300 rpm) for extended periods, the mechanical force reduces the materials to nanoscale dimensions.

This reduction in particle size creates a significantly larger surface area, which is vital for the subsequent chemical reaction.

Why Pre-treatment Matters for Conductivity

Uniform Carbon Coating

In the carbothermal reduction method, glucose acts as the carbon source.

The planetary ball mill ensures that this glucose is dispersed evenly across the iron and lithium precursors.

This deep mixing results in a uniform carbon coating on the final particles, rather than isolated patches of carbon.

Enhancing Electrochemical Performance

LiFePO4 is known for having naturally low electrical conductivity.

The milling process acts as a crucial pre-treatment step to solve this intrinsic limitation.

By ensuring nanoscale dispersion and uniform coating, the mill maximizes the electrochemical conductivity of the final LiFePO4/C composite material.

Understanding the Operational Requirements

The Importance of Specific Parameters

The effectiveness of the ball mill is highly dependent on operational parameters.

The process requires specific rotational speeds and extended grinding durations to achieve the necessary energy input.

Insufficient speed or time will result in poor dispersion, leading to a battery material with suboptimal conductivity and performance.

Making the Right Choice for Your Goal

To maximize the quality of your LiFePO4/C synthesis, consider how you apply the milling process:

- If your primary focus is Reaction Efficiency: Ensure the milling duration is sufficient to reduce all precursors to the nanoscale, maximizing the surface area available for the carbothermal reaction.

- If your primary focus is Electrical Conductivity: Prioritize the deep mixing of glucose to guarantee a continuous, uniform carbon network throughout the composite.

The planetary ball mill is the bridge between raw chemical ingredients and a highly conductive, electrochemically active battery material.

Summary Table:

| Process Function | Mechanism | Impact on Synthesis |

|---|---|---|

| Deep Mixing | Homogenization of precursors (FePO4, Li2CO3, Glucose) | Ensures chemical uniformity and reaction efficiency |

| Size Reduction | High-energy grinding at 300+ RPM | Breaks particles down to the nanoscale for higher surface area |

| Carbon Coating | Intense mechanical dispersion of glucose | Creates a continuous carbon network for superior conductivity |

| Pre-treatment | Mechanical activation of precursors | Lowers reaction energy and enhances electrochemical performance |

Elevate Your Battery Material Synthesis with KINTEK

Precise control over particle size and carbon dispersion is the difference between a standard battery and a high-performance power cell. KINTEK provides industry-leading planetary ball mills and high-temperature furnace systems—including Muffle, Tube, and Vacuum furnaces—specifically designed for the rigorous demands of LiFePO4/C carbothermal reduction.

Backed by expert R&D and manufacturing, our systems are fully customizable to meet your unique lab or production requirements. Ensure uniform coating and nanoscale precision today.

Contact KINTEK for a Professional Consultation

Visual Guide

References

- Ziyang Xu, Jingkui Qu. Sustainable Utilization of Fe(Ⅲ) Isolated from Laterite Hydrochloric Acid Lixivium via Ultrasonic-Assisted Precipitation to Synthesize LiFePO4/C for Batteries. DOI: 10.3390/ma17020342

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

People Also Ask

- Why are high-purity alumina tubes and crucibles preferred for high-temperature smelting? Ensure Maximum Sample Purity

- Why are fly ash geopolymer specimens subjected to 60 °C drying? Master Accelerated Curing for Maximum Strength

- What are the functions of a boron nitride (BN) crucible and internal packing powder? Optimize Si3N4 Sintering Now

- How does the design of a graphite box optimize the sulfurization of Sb thin films? Key Insights for Film Uniformity

- What are the primary functions of the vacuum pump system and inert gases? Achieve High-Purity Atomization

- What is the specific function of the water circulation cooler in zirconium sponge processing? Key for Purity & Safety

- What are the functions of a high vacuum mechanical pump in Ga2O3 PETO? Ensure Purity in Film Preparation

- What is the significance of using ceramic balls of varying diameters? Optimize Reactor Flow and Filtration