In high-temperature reactors, utilizing ceramic balls of varying diameters (such as 3mm and 10mm) is a critical strategy for stabilizing the reaction environment. These inert packing materials provide essential structural support and optimize the distribution of reaction gases, while simultaneously acting as a barrier to prevent fine coke particles from clogging exhaust piping.

By combining different sizes of inert ceramic packing, engineers can create a reactor bed that maximizes heat exchange efficiency and maintains consistent gas flow, effectively mitigating the risk of downstream blockages.

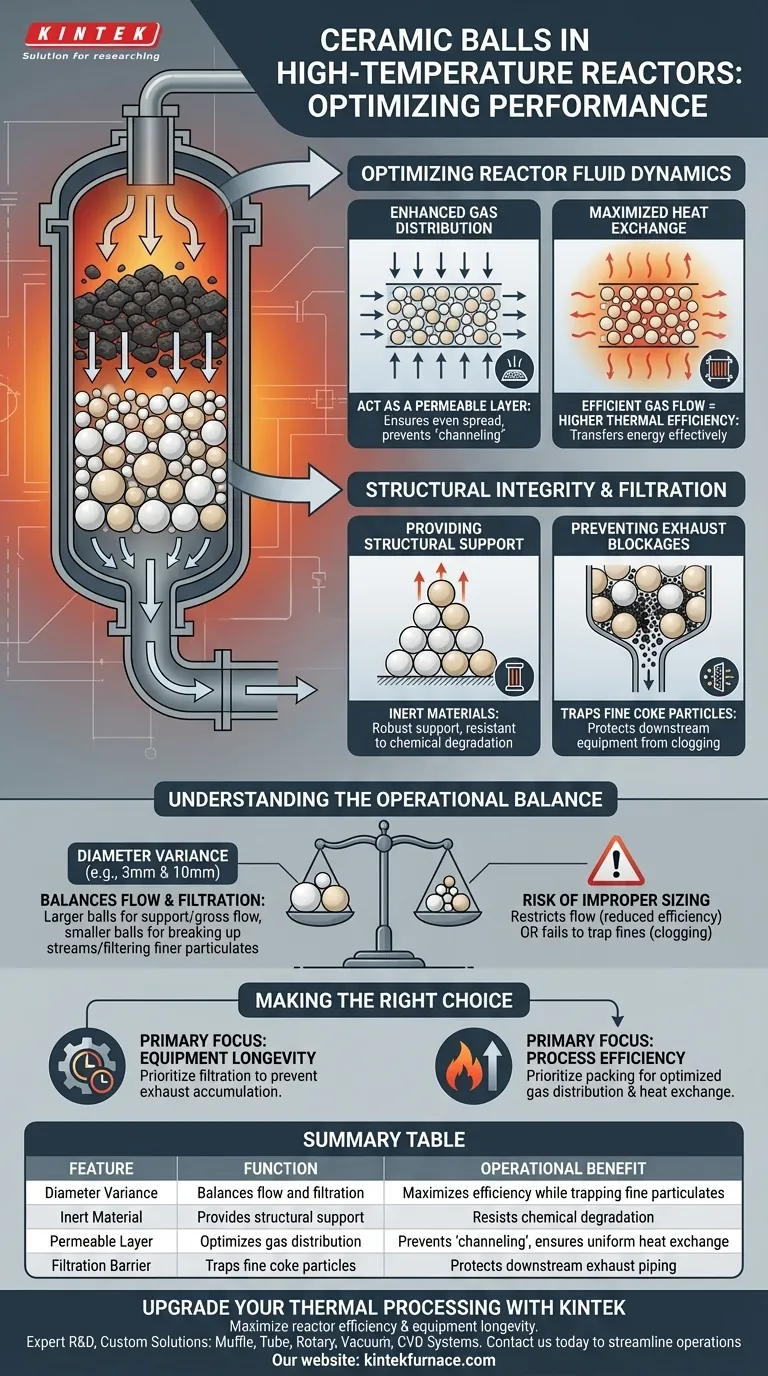

Optimizing Reactor Fluid Dynamics

To ensure a high-temperature reactor operates efficiently, you must control how gases move through the fuel or reactant bed.

Enhancing Gas Distribution

The primary function of these ceramic balls is to optimize the flow of reaction gases. By acting as a permeable layer, they ensure the gas spreads evenly through the coke particles.

Uniform distribution is vital. It prevents "channeling," where gas bypasses the reactants, ensuring the entire bed participates in the reaction.

Maximizing Heat Exchange

Efficient gas distribution directly correlates to thermal efficiency. When the flow is optimized by the packing material, heat exchange efficiency is significantly enhanced.

This ensures that the thermal energy generated or required by the reactor is transferred effectively throughout the system.

Structural Integrity and Filtration

Beyond fluid dynamics, the physical properties of the ceramic balls play a crucial role in the mechanical stability of the reactor internals.

Providing Structural Support

High-temperature reactors require materials that can withstand extreme environments without degrading.

Because these ceramic balls are inert materials, they provide robust structural support for the reactor bed without chemically reacting with the process media.

Preventing Exhaust Blockages

One of the most critical roles of this packing material is filtration. The reactor generates fine coke particles that can be detrimental to downstream equipment.

The ceramic balls effectively trap these fines. This prevents them from entering and clogging the exhaust piping, which is a common cause of operational downtime.

Understanding the Operational Balance

While using ceramic balls offers clear benefits, effective implementation requires understanding the balance between flow and filtration.

The Role of Diameter Variance

The reference highlights the use of distinct diameters, such as 3mm and 10mm. Using a single size often fails to achieve all objectives simultaneously.

Larger balls generally offer better structural support and gross flow capacity, while smaller balls are more effective at breaking up flow streams and filtering finer particulates.

The Risk of Improper Sizing

If the packing material is not correctly sized for the specific coke particles present, the system risks either restricting flow too heavily (reducing efficiency) or failing to trap the fine particles (leading to clogging). Success depends on utilizing the varying diameters to bridge this gap.

Making the Right Choice for Your Goal

The selection of packing material diameters should be driven by the specific operational challenges of your reactor.

- If your primary focus is Equipment Longevity: Prioritize the filtration capability of the packing to ensure fine coke particles do not accumulate in the exhaust piping.

- If your primary focus is Process Efficiency: Focus on the packing configuration that optimizes gas distribution to maximize heat exchange across the coke bed.

Strategic use of varying ceramic diameters transforms a simple packing material into a sophisticated tool for flow control and system protection.

Summary Table:

| Feature | Function | Operational Benefit |

|---|---|---|

| Diameter Variance | Balances flow and filtration | Maximizes efficiency while trapping fine particulates |

| Inert Material | Provides structural support | Resists chemical degradation in high-temperature beds |

| Permeable Layer | Optimizes gas distribution | Prevents 'channeling' and ensures uniform heat exchange |

| Filtration Barrier | Traps fine coke particles | Protects downstream exhaust piping from costly clogging |

Upgrade Your Thermal Processing with KINTEK

Maximize your reactor efficiency and equipment longevity with solutions designed for the most demanding high-temperature environments. Backed by expert R&D and manufacturing, KINTEK offers a wide range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other lab high-temperature furnaces—all fully customizable to meet your unique research or production needs.

Don't let inefficient gas distribution or downstream blockages stall your progress. Contact us today to discover how our high-performance thermal systems can streamline your operations and deliver superior material results.

Visual Guide

References

- P. Nanthagopal R. Sachithananthan. Analytical Review on Impact of Catalytic Coke Formation on Reactor Surfaces During the Thermal Cracking Process. DOI: 10.5281/zenodo.17985550

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What roles do high-purity graphite molds play in SPS? Unlock the Secret to Superior Spark Plasma Sintering

- What is the primary function of a high-purity alumina crucible in PrVSb3 synthesis? Ensure Chemical Inertness & Purity

- What is the function of glass tubes in molten-core thermal drawing? Precision Shaping and Chemical Isolation

- Why is a vacuum pumping system essential for DD6 alloy and ceramic shell experiments? Achieve High-Purity Results

- What is the function of a graphite plate in microwave cladding? Ensure Purity & Thermal Uniformity for HEA Synthesis

- Why are vacuum-sealed quartz tubes required for SnSe melting? Ensure Purity & Stoichiometry

- What are the specific functions of the grinder and laboratory oven during sugarcane-based activated carbon preparation?

- Why are alumina ceramic tubes preferred for high-temperature furnaces? Ensure Stability and Control Up to 1800°C