For high-temperature furnaces, alumina ceramic tubes are the preferred choice due to a unique combination of properties that ensure operational stability, environmental control, and safety. Their ability to withstand extreme temperatures up to 1800°C, resist chemical corrosion, and remain dimensionally stable under heat makes them uniquely suited for creating a reliable and isolated process environment.

The preference for alumina tubes goes beyond mere heat resistance. Their true value lies in their ability to create a highly stable and controllable environment, isolating the internal process from the external heating elements both thermally and chemically, which is critical for consistent and safe furnace operation.

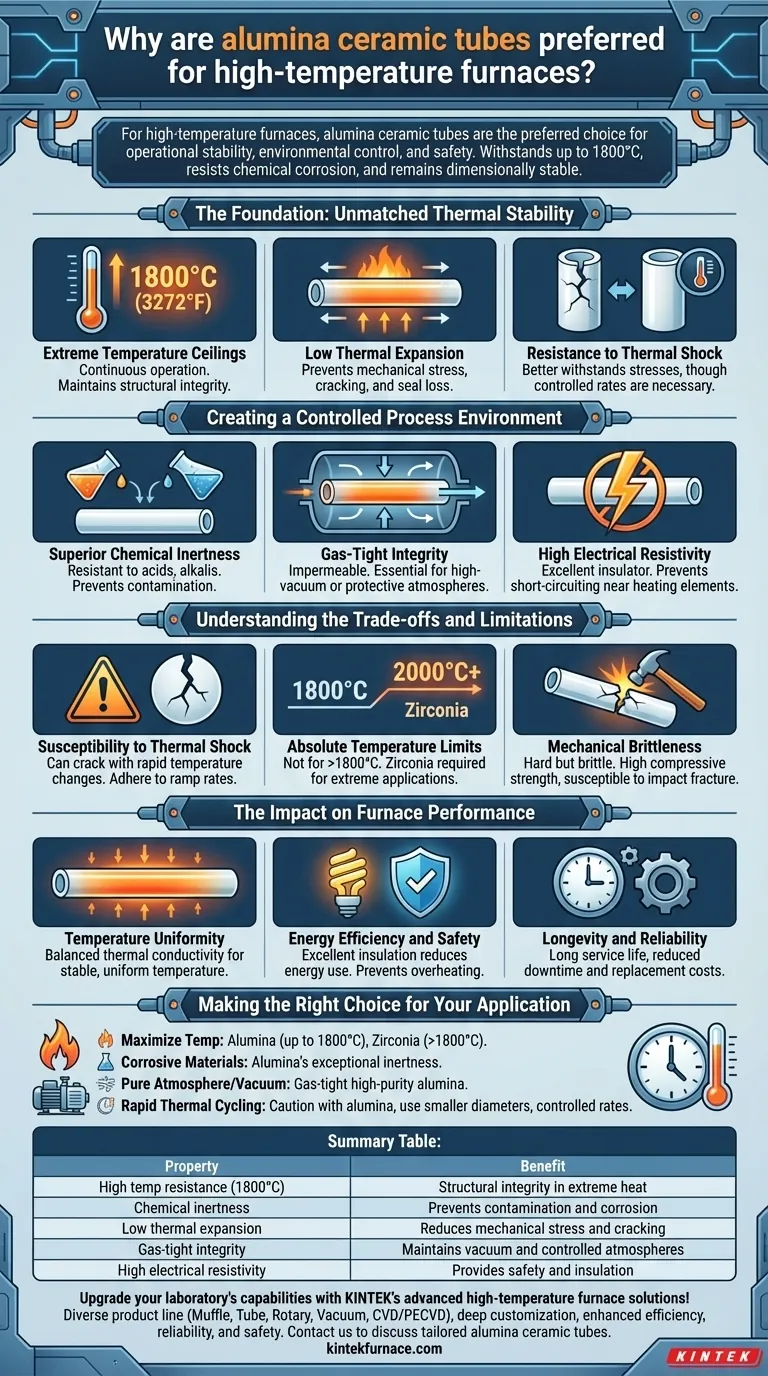

The Foundation: Unmatched Thermal Stability

The primary function of a furnace tube is to endure and manage extreme heat without failing. Alumina (aluminum oxide, Al₂O₃) ceramics are engineered specifically for this purpose.

Extreme Temperature Ceilings

High-purity alumina tubes can operate continuously at temperatures up to 1800°C (3272°F). This high refractoriness ensures the tube maintains its structural integrity well within the operating range of most industrial and laboratory furnaces.

Low Thermal Expansion

Alumina exhibits very low thermal expansion, meaning it does not significantly change its size or shape when heated. This property is crucial for preventing mechanical stress, cracking, and loss of seal integrity as the furnace cycles through extreme temperatures.

Resistance to Thermal Shock

While all ceramics are susceptible to thermal shock (cracking from rapid temperature changes), alumina possesses a high resistance relative to other materials. This allows it to better withstand the stresses of heating and cooling, although controlled rates are still necessary for optimal lifespan.

Creating a Controlled Process Environment

A furnace is more than a hot box; it's a controlled reactor. Alumina tubes provide the isolation necessary to manage the internal environment with precision.

Superior Chemical Inertness

Alumina is chemically inert and highly resistant to corrosion from acids, alkalis, and other volatile process materials. This ensures that the tube does not react with or contaminate the materials being processed, a critical factor in semiconductor manufacturing and chemical synthesis.

Gas-Tight Integrity

High-density alumina tubes are impermeable and gas-tight. This property is essential for applications requiring a high-vacuum environment or a specific protective atmosphere (e.g., Argon, Nitrogen), preventing leaks that would compromise the process.

High Electrical Resistivity

Contrary to some misconceptions, alumina is an excellent electrical insulator. This high resistivity is a key safety and design feature, as it prevents short-circuiting and allows electric heating elements to be placed directly on or near the tube without risk.

Understanding the Trade-offs and Limitations

No material is perfect. Understanding the limitations of alumina is key to its proper application and avoiding premature failure.

Susceptibility to Thermal Shock

Despite its relative resistance, alumina can still crack if heated or cooled too quickly. This risk is more pronounced in larger-diameter tubes. Best practice involves adhering to manufacturer-recommended ramp rates to minimize thermal stress.

Absolute Temperature Limits

While excellent up to 1800°C, alumina is not suitable for the most extreme applications. For temperatures approaching 2000°C (3600°F) and beyond, more specialized ceramics like Zirconia are required.

Mechanical Brittleness

Like most ceramics, alumina is hard but brittle. It has high compressive strength but is susceptible to fracture from mechanical impact or shock. Careful handling during installation and maintenance is essential.

The Impact on Furnace Performance

The material properties of the alumina tube directly translate to the overall performance, efficiency, and reliability of the furnace system.

Temperature Uniformity

Alumina's thermal conductivity is balanced—high enough to efficiently transfer heat from the external elements to the process zone, yet low enough to help maintain a stable, uniform temperature profile across the length of the tube.

Energy Efficiency and Safety

By providing excellent thermal insulation and stability, the tube helps the system maintain its setpoint temperature with less energy. Its electrical insulating properties also prevent overheating and failure of the heating elements.

Longevity and Reliability

The combined resistance to heat, chemical attack, and wear means alumina tubes have a long service life, reducing downtime and replacement costs in demanding industrial environments like metallurgy and glass production.

Making the Right Choice for Your Application

Selecting the right tube material requires aligning its properties with your primary operational goal.

- If your primary focus is maximum operating temperature: Alumina is the industry standard for furnaces operating up to 1800°C; for higher temperatures, you must consider Zirconia.

- If your primary focus is processing corrosive materials: Alumina's exceptional chemical inertness makes it an ideal and non-reactive choice for aggressive chemical environments.

- If your primary focus is maintaining a pure atmosphere or vacuum: The gas-tight integrity of high-purity alumina is a non-negotiable feature for these applications.

- If your primary focus is rapid thermal cycling: Exercise caution with alumina by selecting smaller diameter tubes and programming controlled heating and cooling rates to mitigate thermal shock risk.

Ultimately, choosing alumina is a decision for predictable stability and control in environments where other materials would fail.

Summary Table:

| Property | Benefit |

|---|---|

| High temperature resistance (up to 1800°C) | Ensures structural integrity in extreme heat |

| Chemical inertness | Prevents contamination and corrosion in processes |

| Low thermal expansion | Reduces mechanical stress and cracking risks |

| Gas-tight integrity | Maintains vacuum and controlled atmospheres |

| High electrical resistivity | Provides safety and insulation for heating elements |

Upgrade your laboratory's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, delivering enhanced efficiency, reliability, and safety. Contact us today to discuss how we can support your high-temperature applications with tailored alumina ceramic tubes and more!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What other types of reactions can tube furnaces be used for? Explore Versatile Thermal Processes for Your Lab

- What types of production processes benefit from the thermal uniformity of tube furnaces? Enhance Precision in Material Processing

- In which industries is the tube furnace commonly used? Essential for Materials Science, Energy, and More

- How do roller kilns and tube furnaces differ in their use of Alumina ceramic tubes? Compare Transport vs. Containment

- What is a tubular furnace? Precision Heating for Lab and Industrial Applications