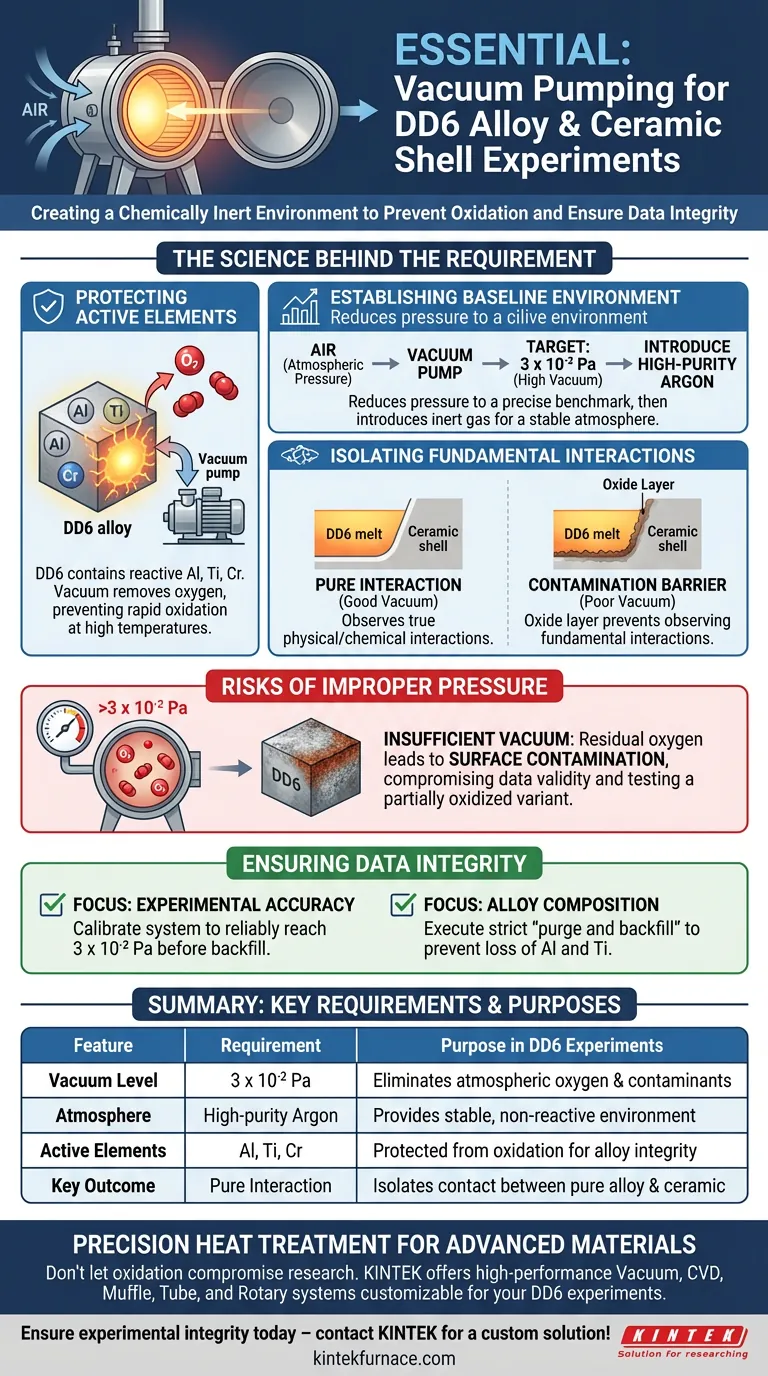

A vacuum pumping system is critical for creating a chemically inert environment essential for high-temperature alloy experiments. By reducing the furnace pressure to a high vacuum level of 3 x 10^-2 Pa before introducing inert gas, the system eliminates atmospheric contaminants. This step is non-negotiable for preventing the oxidation of reactive elements within the DD6 alloy during the heating process.

The primary function of the vacuum system is to protect the chemical integrity of the DD6 alloy. By stripping away oxygen, it prevents active elements like aluminum, titanium, and chromium from reacting with the atmosphere, ensuring that the study isolates the interaction between the metal and the ceramic shell rather than surface oxides.

The Science Behind the Vacuum Requirement

Protecting Active Elements

DD6 alloy is composed of various elements, including highly reactive ones such as aluminum, titanium, and chromium.

These active elements have a strong affinity for oxygen, particularly at the elevated temperatures required for melting.

Without a vacuum system to remove the air, these elements would undergo rapid, unintended oxidation.

Establishing the Baseline Environment

The experiment requires a specific environmental sequence to ensure purity.

The system must first reduce the internal furnace pressure to a precise high vacuum benchmark of 3 x 10^-2 Pa.

Once this vacuum level is achieved, high-purity argon is introduced to create a stable, non-reactive atmosphere for the duration of the melt.

Isolating Fundamental Interactions

The core goal of the experiment is to observe the physical and chemical interactions between the DD6 melt and the ceramic shell material.

If oxidation occurs due to a poor vacuum, an oxide layer forms on the surface of the alloy.

This oxide layer acts as a contamination barrier, preventing you from observing the true fundamental interactions between the pure alloy and the ceramic.

Understanding the Risks of Improper Pressure

The Consequence of Insufficient Vacuum

If the pumping system fails to reach the target of 3 x 10^-2 Pa, residual oxygen remains in the chamber.

Even trace amounts of oxygen can lead to surface contamination of the alloy.

This compromises the validity of the data, as you are no longer testing the DD6 alloy in its intended state, but rather a partially oxidized variant.

Ensuring Data Integrity in Your Setup

To guarantee valid results when working with DD6 and ceramic shells, precise atmospheric control is required.

- If your primary focus is experimental accuracy: Ensure your vacuum system is calibrated to reliably reach 3 x 10^-2 Pa before the introduction of any backfill gas.

- If your primary focus is alloy composition: Verify that the "purge and backfill" cycle is executed strictly to prevent the loss of active elements like Aluminum and Titanium.

A robust vacuum system is the only way to ensure the chemistry you observe is the chemistry intended by the experiment design.

Summary Table:

| Feature | Requirement | Purpose in DD6 Experiments |

|---|---|---|

| Vacuum Level | 3 x 10^-2 Pa | Eliminates atmospheric oxygen and contaminants |

| Atmosphere | High-purity Argon | Provides a stable, non-reactive testing environment |

| Active Elements | Al, Ti, Cr | Protected from oxidation to maintain alloy integrity |

| Key Outcome | Pure Interaction | Isolates contact between pure alloy and ceramic shell |

Precision Heat Treatment for Advanced Materials

Don’t let oxidation compromise your research data. KINTEK provides the high-performance vacuum and thermal solutions required for sensitive metallurgical studies. Backed by expert R&D and manufacturing, we offer Vacuum, CVD, Muffle, Tube, and Rotary systems, all customizable to reach the precise pressure levels your DD6 alloy experiments demand.

Ensure your experimental integrity today—contact KINTEK for a custom furnace solution!

Visual Guide

References

- Guangyao Chen, Chonghe Li. Effect of Kaolin/TiO2 Additions and Contact Temperature on the Interaction between DD6 Alloys and Al2O3 Shells. DOI: 10.3390/met14020164

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- Vacuum Heat Treat Sintering and Brazing Furnace

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

People Also Ask

- What are the roles of rotameters and digital flow controllers in pneumatic systems? Enhance Precision and Testing

- What are the performance parameters of a circulating water vacuum pump? Optimize Your Lab's Vacuum Efficiency

- How has the circulating water vacuum pump been received in practical use? Durable, Cost-Effective for Lab Tasks

- What are the benefits of sealing SAC305 solder in vacuum quartz tubes? Ensure High-Reliability Alloy Integrity

- What is the role of a Teflon-lined autoclave in CeO2 synthesis? Achieve Pure, Monodisperse Nanomaterials

- What roles do high-purity graphite molds play in the SPS of copper sulfide? Enhance Your Thermoelectric Material Quality

- How does an evaporation and mixing unit assist in fuel ignition study? Enhance Research with Precise Vapor Control

- What is the significance of using ceramic or quartz sample boats for solid fuels? Ensure Precise Thermal Analysis