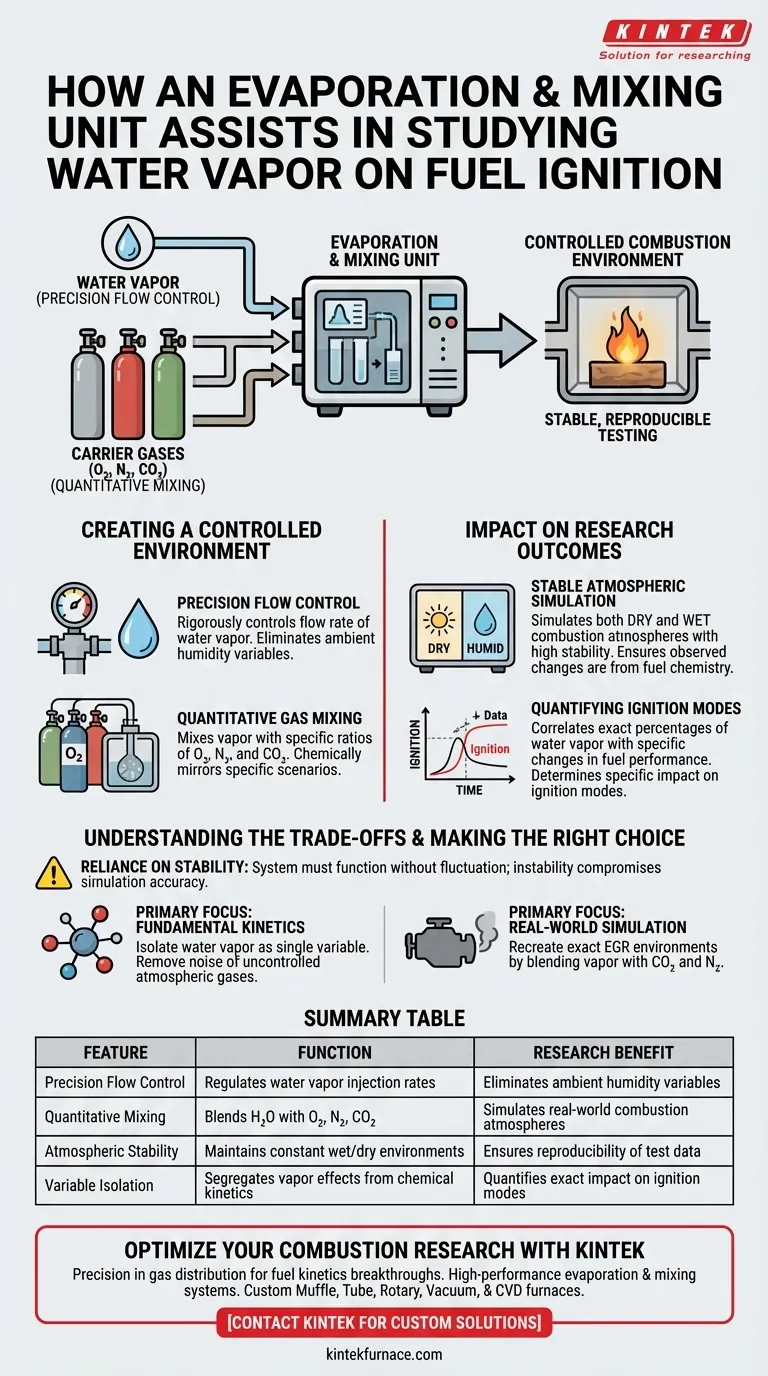

An evaporation and mixing unit serves as a high-precision gas distribution system designed to isolate the critical variables of combustion. By accurately controlling the flow rate of water vapor and quantitatively mixing it with carrier gases like Oxygen ($O_2$), Nitrogen ($N_2$), and Carbon Dioxide ($CO_2$), it creates stable, reproducible environments for testing.

By simulating both dry and wet combustion atmospheres with high stability, this unit enables researchers to move beyond general observations and specifically quantify how varying levels of water vapor alter the ignition modes of different fuels.

Creating a Controlled Combustion Environment

To study ignition accurately, researchers must eliminate environmental variables. An evaporation and mixing unit achieves this through two primary mechanisms.

Precision Flow Control

The unit acts as a rigorous gatekeeper for water vapor. Rather than relying on ambient humidity or approximate injection methods, it precisely controls the flow rate of water vapor entering the system.

Quantitative Gas Mixing

Water vapor is rarely the only gas present during combustion. The unit quantitatively mixes the vapor with specific ratios of other atmospheric components ($O_2$, $N_2$, and $CO_2$). This ensures the test environment chemically mirrors the specific scenario being studied.

The Impact on Research Outcomes

The value of this unit lies in its ability to translate physical control into usable scientific data.

Stable Atmospheric Simulation

Combustion behaves differently in arid conditions versus humid ones. This unit allows for the stable simulation of both dry and wet combustion atmospheres.

By maintaining stability, researchers can ensure that observed changes in ignition are due to the fuel chemistry, not fluctuations in the test environment.

Quantifying Ignition Modes

The ultimate output of using this system is quantifiable data. Researchers can correlate exact percentages of water vapor with specific changes in fuel performance.

This allows for the determination of the specific impact water vapor content has on the ignition modes of various fuels.

Understanding the Trade-offs

While an evaporation and mixing unit provides high-fidelity data, it introduces specific requirements to the experimental process.

Reliance on Stability

The primary advantage of this system is stability; however, this is also its critical dependency. For valid results, the gas distribution system must function without fluctuation.

Any instability in the mixing unit will directly compromise the "dry" or "wet" simulation, rendering the resulting quantification of ignition modes inaccurate.

Making the Right Choice for Your Goal

When designing an experiment to test fuel ignition, consider how this unit aligns with your specific objectives.

- If your primary focus is fundamental chemical kinetics: Use this unit to isolate water vapor as a single variable, removing the noise of uncontrolled atmospheric gases.

- If your primary focus is real-world simulation: Leverage the mixing capabilities to recreate exact exhaust gas recirculation (EGR) environments by blending vapor with $CO_2$ and $N_2$.

Precision in evaporation and mixing is the key to unlocking accurate, reproducible fuel ignition data.

Summary Table:

| Feature | Function in Ignition Studies | Research Benefit |

|---|---|---|

| Precision Flow Control | Regulates water vapor injection rates | Eliminates ambient humidity variables |

| Quantitative Mixing | Blends $H_2O$ with $O_2$, $N_2$, $CO_2$ | Simulates real-world combustion atmospheres |

| Atmospheric Stability | Maintains constant wet/dry environments | Ensures reproducibility of test data |

| Variable Isolation | Segregates vapor effects from chemical kinetics | Quantifies exact impact on ignition modes |

Optimize Your Combustion Research with KINTEK

Precision in gas distribution is the foundation of breakthroughs in fuel kinetics. Backed by expert R&D and manufacturing, KINTEK offers high-performance evaporation and mixing systems alongside our Muffle, Tube, Rotary, Vacuum, and CVD high-temp furnaces—all customizable for your unique lab requirements.

Whether you are simulating exhaust gas recirculation or fundamental chemical kinetics, our solutions provide the stability and accuracy your data demands. Contact KINTEK today to discuss your custom furnace and gas distribution needs and see how our expertise can drive your research forward.

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the specific function of a laboratory high-temperature furnace? Master Lost-PLA Burnout Success

- What is the specific function of the water circulation cooler in zirconium sponge processing? Key for Purity & Safety

- What is the function of a vacuum rotary vane pump in hydrogen measurement? Ensure High-Purity Gas Analysis Baseline

- What is the function of a graphite crucible with a threaded lid? Key to Successful Mg3Sb2 Synthesis

- Why is a quartz reaction tube ideal for tubular carbon nanofibers? High-Purity Synthesis Solutions

- Why is a vacuum pump utilized in research concerning the reaction of magnesium with carbon dioxide and nitrogen? Ensure Data Integrity

- How is a vacuum pump system used to simulate high-altitude gasification conditions? Replicate 3000m Pressure Levels

- What is the primary function of graphitized quartz glass tubes in the synthesis of Bi2Se3-Nd2Se3 alloys?