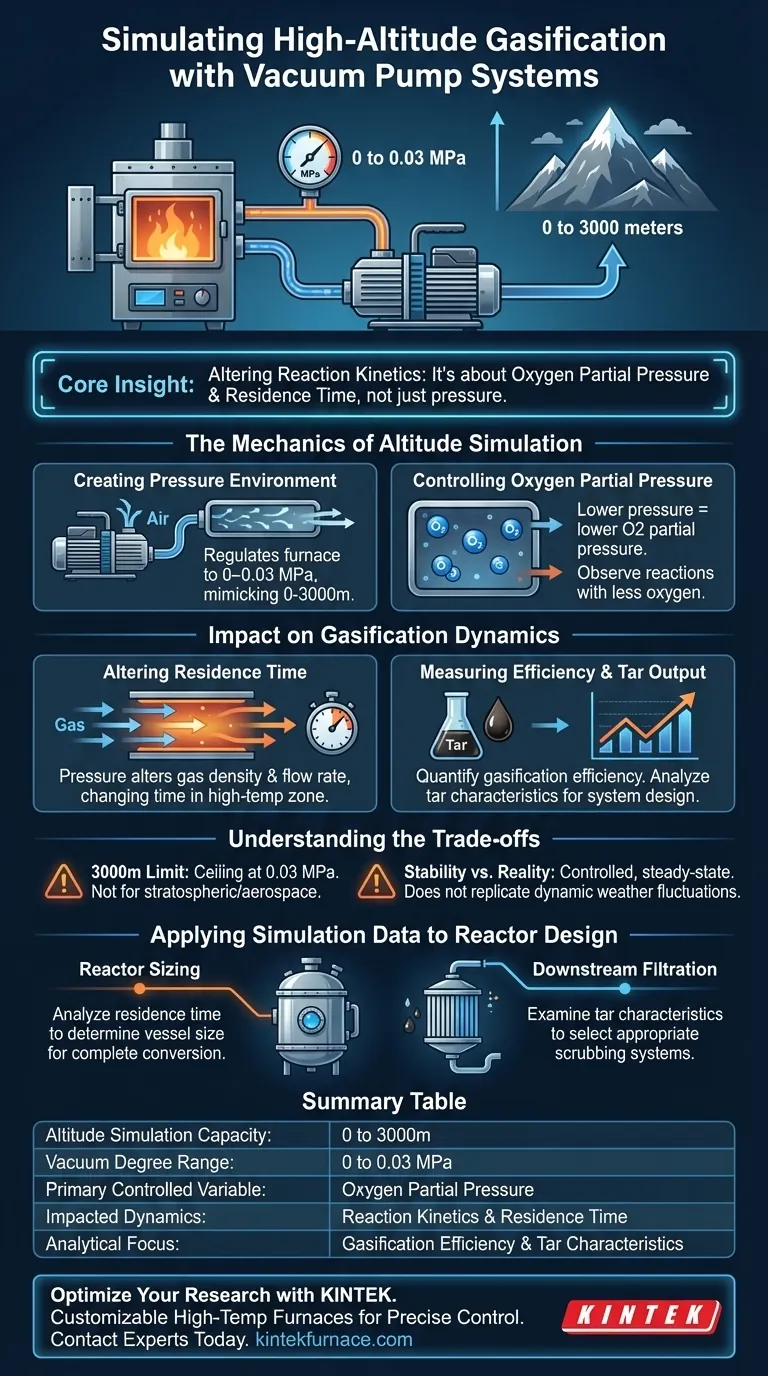

Precise pressure regulation is the mechanism by which a vacuum pump system replicates high-altitude environments for gasification studies. The system actively controls the internal vacuum degree of the furnace, maintaining a range between 0 and 0.03 MPa. This specific pressure window allows researchers to accurately simulate the atmospheric conditions found at altitudes ranging from sea level up to 3000 meters.

Core Insight Simulating altitude is not merely about lowering pressure; it is about altering reaction kinetics. By manipulating the vacuum degree, the system fundamentally changes the oxygen partial pressure and gas residence time, providing critical data on how efficiency and tar production shift in thinner air.

The Mechanics of Altitude Simulation

Creating the Pressure Environment

To mimic high-altitude conditions, the vacuum pump regulates the furnace's internal pressure to match specific "vacuum degrees."

The system operates within a specific window of 0 to 0.03 MPa. This range corresponds to the atmospheric pressure drops experienced between 0 and 3000 meters above sea level.

Controlling Oxygen Partial Pressure

A primary function of the vacuum system is to modify the oxygen partial pressure within the reaction zone.

As the pump lowers the overall pressure to simulate higher altitudes, the partial pressure of oxygen decreases. This allows researchers to observe how fuel reacts when oxygen is less physically available, a critical factor in combustion and gasification efficiency.

Impact on Gasification Dynamics

Altering Residence Time

The vacuum pump directly influences the reaction residence time—the duration reactants remain in the high-temperature zone.

Changes in pressure alter the density and flow rate of the gases passing through the furnace. By adjusting the vacuum degree, researchers can study how these flow dynamic changes impact the conversion of fuel into gas.

Measuring Efficiency and Tar Output

The ultimate goal of this pressure regulation is to quantify changes in gasification efficiency.

Furthermore, the system enables the analysis of tar characteristics. Researchers use the controlled pressure environment to determine if high-altitude conditions lead to higher tar content or different tar compositions, which are critical metrics for system maintenance and longevity.

Understanding the Trade-offs

Simulation Range Limitations

It is important to note that this specific system is calibrated for a ceiling of 3000 meters (0.03 MPa vacuum degree).

While effective for terrestrial high-altitude applications, this setup cannot simulate extreme stratospheric or aerospace environments. It is strictly limited to the operational range defined by the pump's capacity.

Stability vs. Reality

Simulating altitude via a vacuum pump creates a controlled, steady-state low-pressure environment.

However, real-world high-altitude environments may involve fluctuating barometric pressures and temperature variables that a static vacuum setting does not perfectly replicate. The data represents ideal pressure conditions rather than dynamic weather patterns.

Applying Simulation Data to Reactor Design

To maximize the value of high-altitude gasification studies, you must correlate pressure data with specific design parameters.

- If your primary focus is reactor sizing: Analyze the changes in residence time at 0.03 MPa to determine if the reactor vessel needs to be larger to achieve complete conversion at altitude.

- If your primary focus is downstream filtration: Examine the tar characteristics observed at simulated altitudes to select scrubbing systems capable of handling the specific tar composition generated in low-pressure environments.

By isolating pressure as a variable, this system provides the baseline physics required to adapt gasification technology for diverse geographic locations.

Summary Table:

| Parameter | Altitude Simulation Capacity |

|---|---|

| Vacuum Degree Range | 0 to 0.03 MPa |

| Equivalent Altitude | 0 to 3000 meters above sea level |

| Primary Controlled Variable | Oxygen Partial Pressure |

| Impacted Dynamics | Reaction Kinetics & Residence Time |

| Analytical Focus | Gasification Efficiency & Tar Characteristics |

Optimize Your Gasification Research for Any Altitude

Don't let geographic constraints limit your material science. KINTEK provides industry-leading laboratory solutions backed by expert R&D and precision manufacturing. Whether you require Muffle, Tube, Rotary, Vacuum, or CVD systems, our high-temperature furnaces are fully customizable to meet your specific pressure and thermal requirements.

Ready to achieve precise atmospheric control in your lab? Contact KINTEK Experts Today to discuss your unique simulation needs and discover how our advanced furnace technology can enhance your data accuracy.

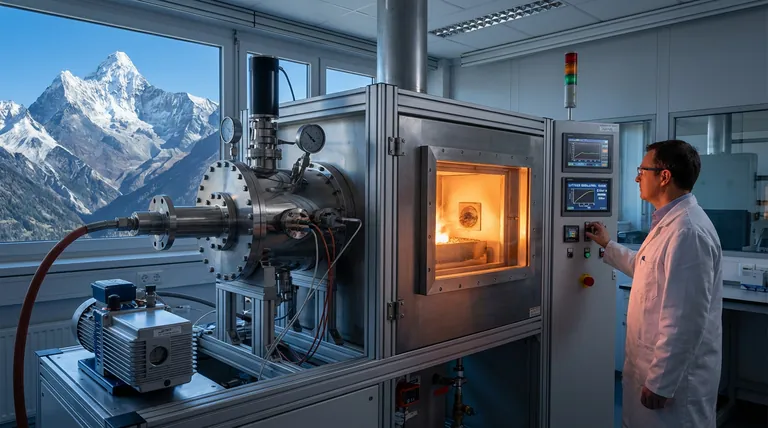

Visual Guide

References

- Chen Dai, Cai Yu. Characteristics of Low-Temperature Gasification Products from Wheat Straw in a Fluidized Bed Based on Cement Production Process. DOI: 10.3390/en17081943

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- Why is a high-performance vacuum pump system necessary for AlV55 alloys? Ensure Aerospace-Grade Purity and Precision

- Why is dimensional accuracy important for alumina ceramic furnace tubes? Ensure Reliable High-Temp Performance

- What technical considerations justify the use of high-purity alumina crucibles for microwave-assisted metal reduction?

- What is the key technological improvement in the circulating water vacuum pump? Discover the Self-Contained Closed-Loop System

- What are the benefits of 150mm thick ceramic fiber blankets in furnaces? Boost Efficiency and Safety

- What are the common uses for Alumina ceramic tubes? Ideal for High-Temp, Insulation, and Corrosion Resistance

- What is the primary function of graphitized quartz glass tubes in the synthesis of Bi2Se3-Nd2Se3 alloys?

- What are the advantages of using high-purity quartz boats? Ensure Purity in Carbon Nanotube Synthesis