High-purity quartz boats provide essential chemical inertness and thermal stability, ensuring the successful synthesis of nitrogen-enriched carbon nanotubes. Their primary advantage lies in their ability to withstand high-temperature Chemical Vapor Deposition (CVD) and ammonia reduction atmospheres without reacting with metal catalysts or the developing carbon nanostructure.

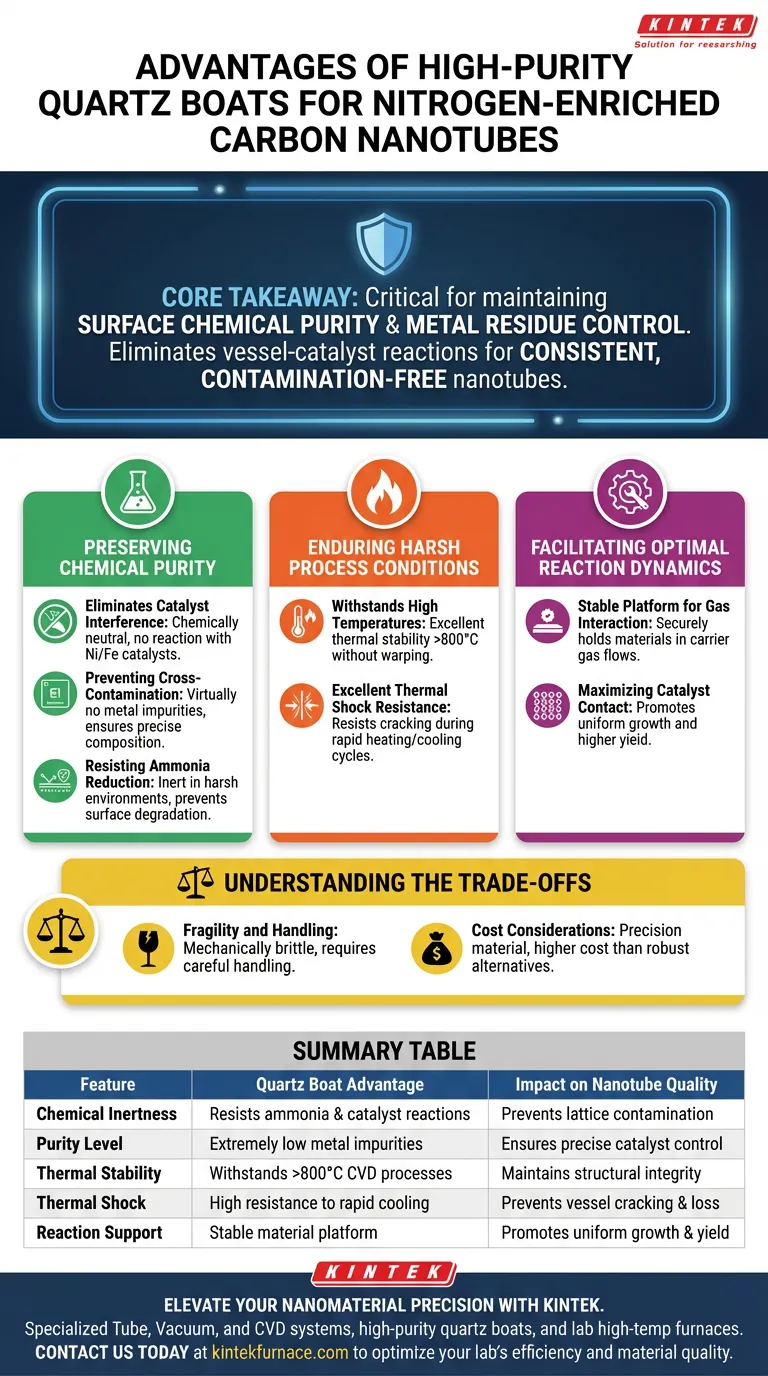

Core Takeaway: The use of high-purity quartz boats is critical for maintaining surface chemical purity and metal residue control. By eliminating reactions between the vessel and the catalyst, you ensure the final nitrogen-enriched carbon nanotubes are consistent and free from container-induced contamination.

Preserving Chemical Purity

Eliminating Catalyst Interference

The most critical function of the quartz boat is to remain chemically neutral. It does not react with metal catalysts (such as nickel or iron) used to grow the nanotubes.

Preventing Cross-Contamination

Because high-purity quartz contains virtually no metal impurities, it prevents the introduction of foreign elements into the reaction. This ensures that the only metal residues found in the final product are the intended catalytic particles, allowing for precise control over the nanotube's composition.

Resisting Ammonia Reduction Atmospheres

Nitrogen-enriched carbon nanotube preparation often requires harsh ammonia reduction environments. High-purity quartz remains inert under these specific chemical conditions, preventing surface degradation that could contaminate the carbon lattice.

Enduring Harsh Process Conditions

Withstanding High Temperatures

The CVD process frequently exceeds temperatures of 800°C. High-purity quartz possesses excellent thermal stability, maintaining its structural integrity without warping or melting during these intense heating cycles.

Excellent Thermal Shock Resistance

In addition to sustained heat, the process may involve rapid temperature fluctuations. Quartz boats offer superior thermal shock resistance, ensuring the vessel does not crack or fracture when subjected to the rapid heating or cooling inherent in tube furnace operations.

Facilitating Optimal Reaction Dynamics

Stable Platform for Gas Interaction

The boat provides a physically stable platform to hold the raw materials within the furnace. This stability is crucial when materials are exposed to continuous carrier gas flows.

Maximizing Catalyst Contact

By holding the substrate securely, the boat ensures maximum contact between the carbon source vapors and the catalyst bed. This promotes uniform growth and higher yield of the carbon nanotubes.

Understanding the Trade-offs

Fragility and Handling

While chemically superior, quartz is mechanically brittle compared to alternatives like high-alumina ceramic. It requires careful handling to avoid breakage during loading and unloading, as it lacks the high mechanical impact strength of ceramic vessels.

Cost Considerations

High-purity quartz is a precision material. For applications where extreme chemical purity is not the primary constraint, more robust materials like alumina might offer a more durable, albeit less inert, solution.

Making the Right Choice for Your Goal

To maximize the quality of your nitrogen-enriched carbon nanotubes, match your vessel choice to your specific experimental priorities:

- If your primary focus is strict chemical purity: Use high-purity quartz to eliminate cross-contamination and ensure the boat remains inert during ammonia reduction.

- If your primary focus is mechanical durability: Evaluate if the slight risk of impurity from a high-alumina ceramic boat is acceptable in exchange for greater resistance to physical breakage.

Selecting the correct vessel is not just about holding the sample; it is about guaranteeing the chemical integrity of your final nanomaterial.

Summary Table:

| Feature | Quartz Boat Advantage | Impact on Nanotube Quality |

|---|---|---|

| Chemical Inertness | Resists ammonia & catalyst reactions | Prevents lattice contamination |

| Purity Level | Extremely low metal impurities | Ensures precise catalyst control |

| Thermal Stability | Withstands >800°C CVD processes | Maintains structural integrity |

| Thermal Shock | High resistance to rapid cooling | Prevents vessel cracking & loss |

| Reaction Support | Stable material platform | Promotes uniform growth & yield |

Elevate Your Nanomaterial Precision with KINTEK

High-performance carbon nanotube synthesis requires equipment that never compromises on purity. Backed by expert R&D and manufacturing, KINTEK offers specialized Tube, Vacuum, and CVD systems, along with high-purity quartz boats and lab high-temp furnaces—all customizable for your unique research needs.

Don't let vessel-induced contamination undermine your results. Contact us today to discover how our high-purity components and custom furnace solutions can optimize your lab's efficiency and material quality.

Visual Guide

References

- Neeraj Gupta, Alberto Villa. Metal-Free Catalytic Conversion of Veratryl and Benzyl Alcohols through Nitrogen-Enriched Carbon Nanotubes. DOI: 10.3390/c10010013

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why are high-purity alumina crucibles used for phosphor synthesis? Ensure Maximum Luminescence and Spectral Purity

- Why are ceramic crucibles required for the high-temperature calcination of dolomite? Ensure High-Purity Results

- Why is a vacuum pumping system essential for DD6 alloy and ceramic shell experiments? Achieve High-Purity Results

- What information does laboratory XRD provide for Gallium Sulfide? Master GaS Single Crystal Characterization

- What are the primary functions of multilayer fixtures within a lithium battery vacuum oven? Optimize Your Drying Process

- What role does the planetary ball mill play in LLZO mixing? Unlock High-Performance Solid-State Electrolyte Synthesis

- Why is an alumina crucible necessary for g-C3N4 synthesis? Ensure High Purity & Stability in Polycondensation

- Why are laboratory vacuum pumps and pressure gauges essential for aluminum foams? Ensure High-Quality Sintering Results