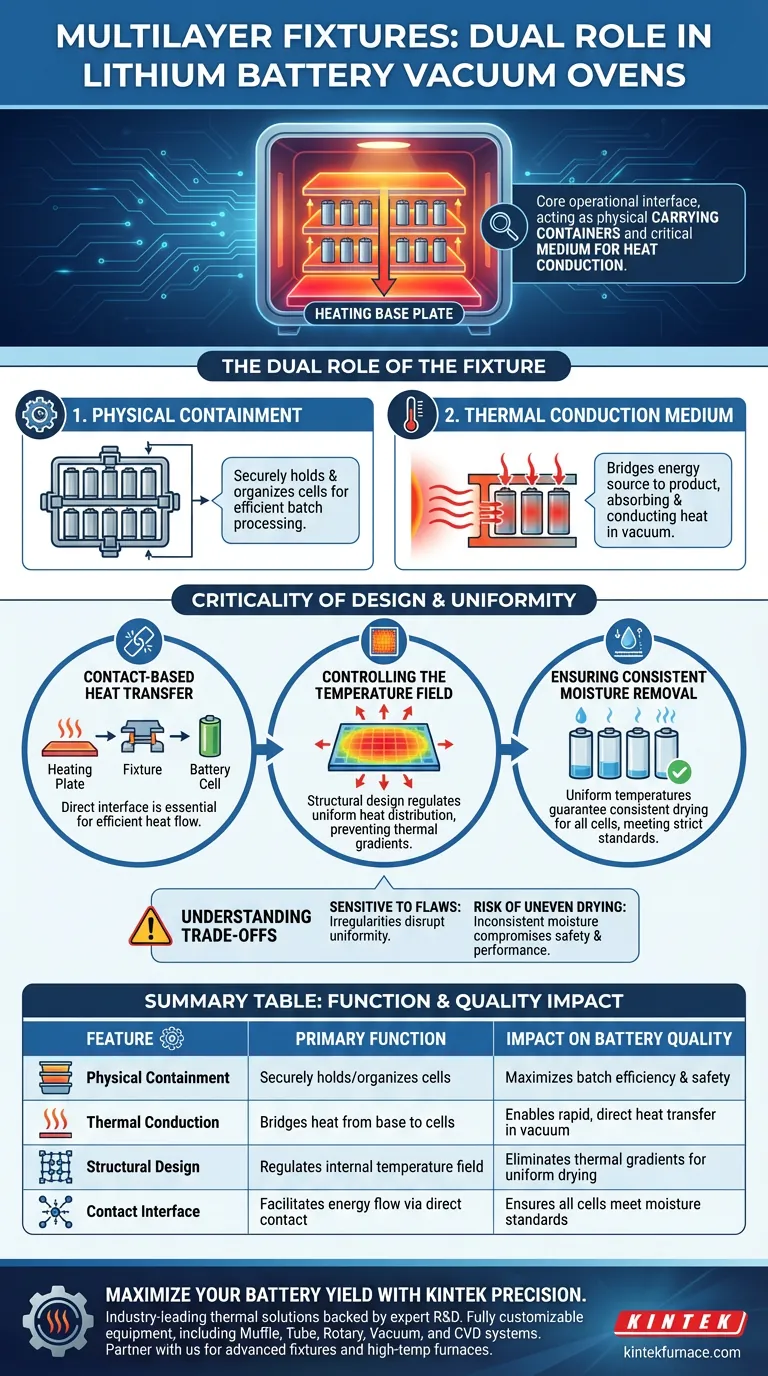

Multilayer fixtures are the operational interface of a lithium battery vacuum oven. Their primary function is twofold: they serve as the physical carrying containers for the battery cells and act as the critical medium for heat conduction. By establishing a direct link between the heating base plate and the battery cells, these fixtures facilitate the thermal transfer necessary for the drying process.

The fixture is more than just a storage rack; it is an active component in the manufacturing process. Its structural design dictates the uniformity of the temperature field, which is the deciding factor in ensuring every battery cell achieves consistent, standard-compliant moisture levels.

The Dual Role of the Fixture

Physical Containment

At the most basic level, multilayer fixtures function as carrying containers. They securely hold the batteries in place, organizing the batch for efficient processing within the vacuum environment.

Thermal Conduction Medium

More importantly, the fixture acts as the core medium for heat transfer. In a vacuum environment where convection is minimized, the fixture bridges the gap between the energy source and the product. It absorbs thermal energy from the heating system and conducts it directly to the battery cells.

The Criticality of Design and Uniformity

Contact-Based Heat Transfer

The efficiency of the oven relies on a contact-based design. The fixture must physically interface with the heating base plate. This direct contact allows heat to flow from the plate, through the fixture material, and into the battery cells.

Controlling the Temperature Field

The structural design of the fixture determines how that heat spreads. A well-engineered fixture ensures the temperature field is uniform throughout the oven. It prevents thermal gradients where some areas might be significantly hotter than others.

Ensuring Consistent Moisture Removal

Temperature uniformity is directly linked to product quality. By maintaining even heat distribution, the fixture ensures that moisture levels are reduced consistently across all battery units. This prevents "weak links" in a batch where specific cells might retain excess humidity.

Understanding the Trade-offs

Sensitivity to Structural Flaws

Because the process relies on contact and conduction, the fixture's design is unforgiving. Any irregularities in the fixture's structure can disrupt the uniformity of heat transfer.

The Risk of Uneven Drying

If the fixture fails to distribute heat evenly, the batch will suffer from inconsistent drying. This compromises the safety and performance of the batteries, as variations in moisture content can lead to failure in the field.

Making the Right Choice for Your Process

To ensure high-yield battery production, consider how your fixture design impacts your specific goals:

- If your primary focus is Product Consistency: Prioritize fixtures with precision structural design to guarantee a uniform temperature field across all layers.

- If your primary focus is Quality Assurance: rigorous verification of the fixture's contact surfaces is required to ensure moisture standards are met for every unit.

The multilayer fixture is not a passive accessory, but a precision thermal tool that directly dictates the reliability of your final product.

Summary Table:

| Feature | Primary Function | Impact on Battery Quality |

|---|---|---|

| Physical Containment | Securely holds and organizes battery cells | Maximizes batch efficiency and safety |

| Thermal Conduction | Bridges heat from base plate to cells | Enables rapid, direct heat transfer in a vacuum |

| Structural Design | Regulates the internal temperature field | Eliminates thermal gradients for uniform drying |

| Contact Interface | Facilitates energy flow via direct contact | Ensures all cells meet strict moisture standards |

Maximize Your Battery Yield with KINTEK Precision

In the competitive landscape of energy storage, thermal uniformity is the key to safety and performance. KINTEK provides industry-leading thermal solutions backed by expert R&D and manufacturing. Our diverse range of equipment—including Muffle, Tube, Rotary, Vacuum, and CVD systems—is fully customizable to meet your specific lab or industrial requirements.

Don't let inefficient heat transfer compromise your production standards. Partner with KINTEK to integrate advanced fixtures and high-temp furnace systems designed for precision. Contact our specialists today to discuss your custom project!

Visual Guide

References

- Lili Zhao, Bo Qi. Research on Temperature Field Characteristics of Lithium Battery Vacuum Drying Furnace. DOI: 10.56028/aetr.11.1.63.2024

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How is quartz wool utilized in the assembly of reaction tubes? Optimize Crystal Growth and Flux Separation

- Why are Y2O3 ceramic crucibles preferred over Al2O3 for Y-DD5 superalloys? Discover the Superior Inertness of Yttria

- What role do quartz tubes play in semiconductor manufacturing? Essential for Purity and High-Temp Processes

- Why are high-purity alumina or ceramic boats required in a tube furnace? Protect Your Lab Equipment & Ensure Purity

- How does a high-performance temperature controller contribute to repeatability? Precision for FTO Thin Film Annealing

- What is the key role of a graphite crucible in the vacuum distillation process for magnesium purification? Essential for High-Purity Results

- Why is the pore size of refractory materials significant? Unlocking Precision in Bubble Formation and Oxygen Impact

- What is the purpose of cleaning MgO substrates for ScN growth? Optimize Your Epitaxial Film Quality