In short, the key role of a graphite crucible in vacuum distillation is to serve as a chemically inert and high-temperature-resistant container. This unique combination of properties ensures that the raw magnesium can be heated and evaporated without reacting with the crucible, which is essential for preventing contamination and achieving a high-purity final product.

The graphite crucible is more than just a container; it is an active enabler of the purification process. Its specific material properties—chemical inertness, thermal stability, and high conductivity—are precisely what allow for the efficient separation of magnesium from its impurities in a high-temperature vacuum environment.

The Core Function: An Inert Reaction Vessel

The success of magnesium vacuum distillation hinges on maintaining a pristine environment, free from unwanted chemical reactions. The graphite crucible is the cornerstone of this controlled environment.

Preventing Contamination

The single most critical function of the crucible is its chemical stability. At the process temperature of 650°C or higher, molten magnesium is highly reactive.

The high-purity graphite does not react with the molten magnesium-aluminum alloy. This inertness prevents secondary contamination, where impurities from the container itself would spoil the final product.

Withstanding Extreme Temperatures

The distillation process requires sustained high temperatures. Graphite crucibles exhibit excellent resistance to these conditions, ensuring they do not melt, soften, or degrade.

This structural integrity under heat is fundamental to the safety and reliability of the entire operation.

Ensuring Uniform Heating

Graphite has good thermal conductivity. This property is vital for efficient and stable distillation.

It allows heat from the furnace's heating elements to be transferred uniformly throughout the crude magnesium. This consistent heating ensures a stable evaporation rate, which is critical for producing high-purity magnesium.

How the Crucible Enables the Distillation Process

The crucible does not work in isolation. It functions as part of an integrated system designed for precise metallurgical separation.

The Role in Separation

During distillation, the vacuum system lowers the boiling point of magnesium, causing it to evaporate at a manageable temperature.

The crucible holds the initial charge, and as the magnesium turns into vapor, the less volatile impurities, such as aluminum, are left behind as residue. In this way, the crucible also acts as a collection unit for these other elements.

Interacting with the Broader System

The crucible is the central point where the other systems converge. Graphite heating elements radiate thermal energy directly to the crucible.

Simultaneously, the vacuum system creates a low-pressure environment (often below 10 Pa) around the crucible, preventing oxidation and facilitating the phase change from liquid to vapor.

Understanding the Material Requirements

The choice of graphite is deliberate and based on strict process requirements. Using a substandard material would lead to process failure.

The Critical Need for High Purity

It is not enough to simply use graphite; it must be high-purity graphite.

Any impurities within the crucible material itself could leach into the molten magnesium at high temperatures, defeating the purpose of the purification process.

Structural Integrity Under Vacuum

The crucible must maintain its physical form not only under high heat but also in a low-pressure vacuum environment.

This ensures it can reliably contain the molten metal throughout the lengthy distillation cycle without risk of mechanical failure.

Why Other Materials Fall Short

Most other materials are unsuitable for this application. Metals would either melt or react with the magnesium alloy.

Many ceramics, while heat-resistant, lack the necessary thermal conductivity for uniform heating and can be susceptible to thermal shock and cracking in such a demanding environment.

Making the Right Choice for Your Goal

Selecting a crucible is a foundational decision for the success of any high-temperature vacuum distillation process.

- If your primary focus is maximizing purity: High-purity graphite is non-negotiable to eliminate the risk of secondary contamination from the container itself.

- If your primary focus is process efficiency: A crucible with excellent thermal conductivity is essential for achieving uniform heating and a stable, consistent evaporation rate.

- If your primary focus is operational reliability: The material's proven thermal and structural stability ensures it can withstand the harsh process conditions without failure.

Ultimately, the graphite crucible is the component that makes high-purity magnesium distillation both possible and practical.

Summary Table:

| Key Role | Benefit in Magnesium Purification |

|---|---|

| Chemical Inertness | Prevents secondary contamination by not reacting with molten magnesium. |

| High-Temperature Resistance | Maintains structural integrity at 650°C+ for reliable operation. |

| Uniform Thermal Conductivity | Ensures stable evaporation rates for consistent, high-purity output. |

| High-Purity Material | Eliminates leaching of impurities, crucial for achieving >99.9% purity. |

Achieve Unmatched Purity in Your Metal Purification Processes

Selecting the right high-temperature equipment is critical for the success of vacuum distillation. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, CVD systems, and other lab high-temp furnaces, all customizable for unique needs like magnesium purification.

Our graphite crucibles and vacuum furnaces are engineered for maximum chemical inertness, thermal stability, and efficiency—ensuring your operations achieve the highest purity standards reliably.

Contact us today to discuss your specific application requirements and let our experts help you optimize your purification process!

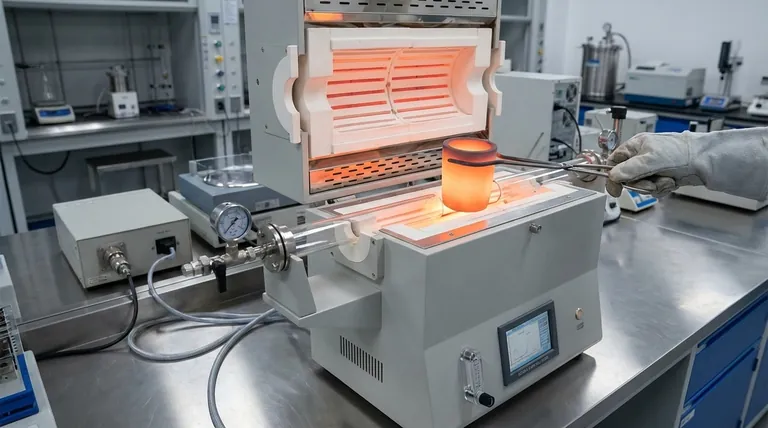

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control