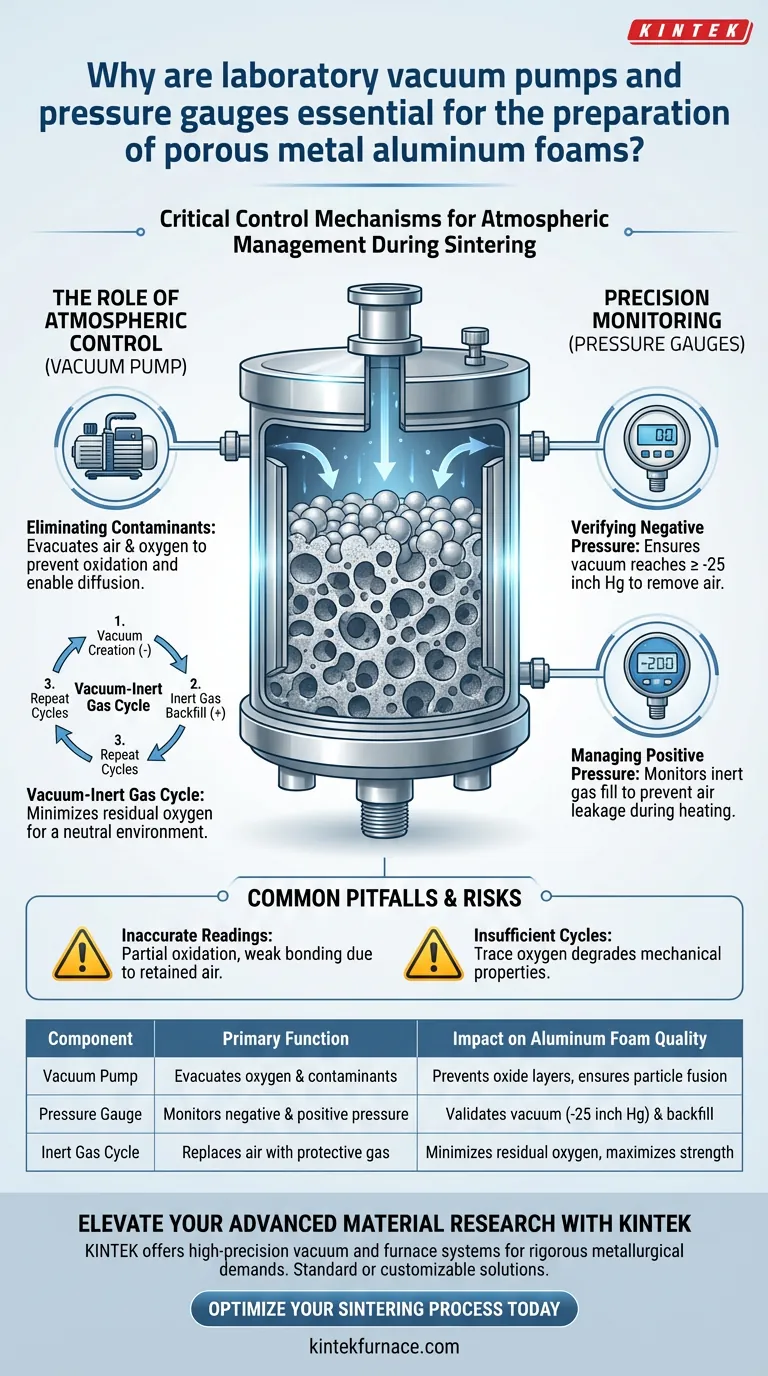

Laboratory vacuum pumps and pressure gauges are the critical control mechanisms for managing the atmospheric environment during the sintering of porous metal aluminum foams. They work in tandem to evacuate reactive air from the processing chamber and verify that the internal conditions are optimal for metallurgical bonding.

The creation of high-quality aluminum foam requires a pristine, oxygen-free environment. Vacuum pumps and gauges enable precise "purge-and-fill" cycles to replace atmospheric air with inert gas, preventing oxidation that would otherwise compromise the material's structural integrity.

The Role of Atmospheric Control

Eliminating Contaminants

The primary function of the laboratory vacuum pump is to evacuate air from the sintering device prior to processing.

By removing the standard atmosphere, you remove oxygen. This is essential because oxygen reacts rapidly with aluminum, creating oxide layers that inhibit proper bonding.

The Vacuum-Inert Gas Cycle

Achieving a truly neutral environment often requires more than a single evacuation.

The process involves multiple vacuum-inert gas cycles. The pump creates a vacuum, and the chamber is then backfilled with an inert gas. Repeating this cycle minimizes residual oxygen concentrations significantly more effectively than a single purge.

Facilitating Diffusion

The ultimate goal of this atmospheric control is to enable diffusion and metallurgical bonding.

When the environment is reduced or neutral, aluminum powder particles can fuse together at the atomic level. This results in a cohesive, strong foam structure rather than a collection of loosely bound, oxidized particles.

Precision Monitoring with Pressure Gauges

Verifying Negative Pressure

High-precision pressure gauges are the "eyes" of the operation, ensuring the vacuum pump is performing correctly.

They monitor negative pressure states, verifying that the system reaches at least -25 inch Hg. Without this specific level of vacuum, too much air remains in the chamber to guarantee a clean sinter.

Managing Positive Pressure

The gauges are equally important during the backfilling stage of the cycle.

They monitor positive pressure states when the chamber is filled with inert gas. This ensures the chamber is slightly pressurized to prevent outside air from leaking back in during the heating process.

Common Pitfalls and Risks

Inaccurate Pressure Readings

If your pressure gauge lacks precision, you may believe you have achieved a sufficient vacuum when you have not.

Even a small amount of retained air can lead to partial oxidation. This results in weak points within the aluminum foam where the powder particles failed to bond completely.

Insufficient Cycle Repetition

Relying on a single vacuum pull is rarely sufficient for high-quality porous metals.

Failing to execute multiple vacuum-inert gas cycles often leaves behind trace oxygen. This remaining oxygen creates a "dirty" environment that degrades the final mechanical properties of the foam.

Ensuring Quality in Foam Preparation

To maximize the quality of your porous metal aluminum foam, align your equipment usage with your specific processing goals:

- If your primary focus is Structural Integrity: Ensure your vacuum pump can consistently pull and hold a vacuum of at least -25 inch Hg to guarantee contaminant removal.

- If your primary focus is Process Consistency: Use high-precision gauges to strictly validate both the negative vacuum limit and the positive inert gas pressure before every heating cycle.

By rigorously controlling the atmosphere through precise pumping and monitoring, you ensure the metallurgical diffusion necessary for strong, reliable aluminum foam.

Summary Table:

| Component | Primary Function | Impact on Aluminum Foam Quality |

|---|---|---|

| Vacuum Pump | Evacuates oxygen and atmospheric contaminants | Prevents oxide layers; ensures atomic-level particle fusion. |

| Pressure Gauge | Monitors negative and positive pressure states | Validates vacuum depth (-25 inch Hg) and inert gas backfill. |

| Inert Gas Cycle | Replaces air with neutral protective gas | Minimizes residual oxygen to maximize mechanical strength. |

Elevate Your Advanced Material Research with KINTEK

Precise atmospheric control is the difference between a weak structure and a high-performance aluminum foam. Backed by expert R&D and manufacturing, KINTEK offers high-precision vacuum systems, Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of metallurgical bonding.

Whether you need a standard solution or a system fully customizable for your unique laboratory needs, our technical team is ready to assist. Contact KINTEK today to optimize your sintering process and ensure the structural integrity of your porous metals.

Visual Guide

References

- María E. Hernández-Rojas, Sandro Báez–Pimiento. A Device with a Controllable Internal Atmosphere, Independent from the Heating Furnace, for Sintering Metal Particles. DOI: 10.1590/1980-5373-mr-2023-0401

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- Why is a high-purity graphite crucible essential for magnesium vacuum distillation? Achieve Maximum Purity & Efficiency

- Why are high-performance insulation accessories necessary during the microwave sintering of zirconia ceramics?

- What advanced material processing applications use graphite crucible furnaces? Unlock Precision in Nanomaterial Synthesis and More

- What are the main components of a Laboratory Furnace? Essential Parts for Precise High-Temperature Processing

- How does a precision programmed cooling system influence the structural integrity of Al2O3-TiC composite materials?

- Why are high-purity alumina crucibles selected as the substrate during the sintering of boron-containing stainless steel?

- What is the function of a vacuum system in PLD? Ensure High-Density, Pure Electrolyte Thin Films

- Where are water circulating vacuum pumps commonly used? Essential for Lab and Industrial Vapor Handling