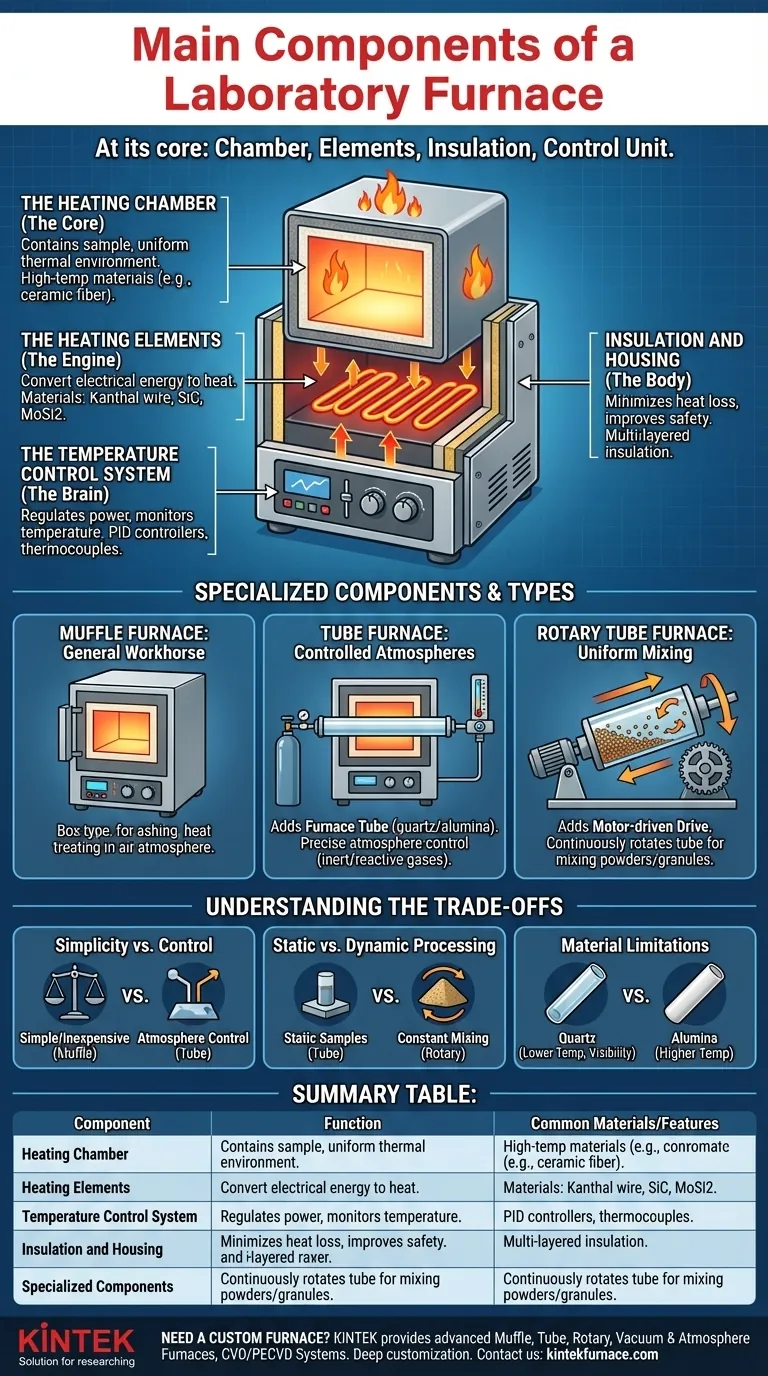

At its core, a laboratory furnace consists of four fundamental components: a heating chamber to contain the sample, heating elements to generate heat, insulation to retain it, and a temperature control unit to regulate the process. These parts work in concert to create a precise, high-temperature environment for materials processing and testing.

While all laboratory furnaces share the same basic building blocks, the specific components and their configuration are determined by the furnace's primary function—whether it's for general-purpose heating, processing in a controlled atmosphere, or uniformly mixing materials.

The Universal Building Blocks of Any Lab Furnace

Every laboratory furnace, regardless of its specific type, is built around a common set of core components. Understanding these parts is the first step to understanding how the entire system functions.

The Heating Chamber (The Core)

The chamber is the insulated enclosure where the sample is placed. It is constructed from high-temperature-resistant materials, such as refractory bricks or ceramic fiber, designed to withstand extreme thermal stress.

This component's primary job is to contain the heat and provide a stable, uniform thermal environment for the material being processed.

The Heating Elements (The Engine)

These are the components responsible for converting electrical energy into heat. They are typically arranged around or within the chamber to provide even temperature distribution.

Common materials for heating elements include high-resistance wire (like Kanthal) or more robust materials like silicon carbide (SiC) or molybdenum disilicide (MoSi2) for higher temperature applications.

The Temperature Control System (The Brain)

This electronic unit is the command center of the furnace. It consists of a thermocouple to measure the chamber's temperature and a controller to regulate the power sent to the heating elements.

Modern systems almost universally use PID (Proportional-Integral-Derivative) controllers for high accuracy. They often feature digital displays, programmable heating cycles, and safety features like over-temperature alarms.

Insulation and Housing (The Body)

Multi-layered insulation is packed between the heating chamber and the outer metal housing. Its purpose is to minimize heat loss, which improves energy efficiency and keeps the exterior surface cool and safe to the touch.

The quality of the insulation directly impacts the furnace's maximum temperature, heating/cooling rates, and operational cost.

Specialized Components for Specific Tasks

Beyond the universal parts, specialized furnaces incorporate unique components to perform specific tasks. The type of furnace you encounter—muffle, tube, or rotary—is defined by these additions.

Muffle Furnaces: The General Workhorse

A muffle furnace is the most common "box" type and generally only includes the four core components described above. Its design is optimized for general-purpose applications like ashing, heat treating, and materials testing in an air atmosphere.

Tube Furnaces: For Controlled Atmospheres

A tube furnace adds a critical component: a furnace tube. This cylindrical tube, often made of quartz, alumina, or mullite, passes through the heating chamber.

This design allows for precise atmosphere control. By sealing the ends of the tube, users can introduce inert or reactive gases via a gas circulation system, preventing oxidation or creating a specific chemical environment for the sample.

Rotary Tube Furnaces: For Uniform Mixing

A rotary tube furnace builds upon the tube furnace design by adding a motor-driven drive mechanism. This system continuously rotates the furnace tube during operation.

This rotation tumbles the material inside, making it ideal for processes involving powders or granules. The constant mixing ensures every particle is uniformly heated and exposed to the controlled atmosphere, which is critical for applications like sintering and calcination. These often include dedicated feed and discharge systems for continuous processing.

Understanding the Trade-offs

Choosing a furnace involves balancing complexity, capability, and cost. Each design presents a distinct set of trade-offs.

Simplicity vs. Control

A standard muffle furnace is simple, robust, and relatively inexpensive. However, it offers no control over the processing atmosphere. A tube furnace adds complexity and cost but provides the critical ability to process samples in a vacuum or a specific gas.

Static vs. Dynamic Processing

A standard tube furnace is perfect for processing static samples. If your material is a powder or granule that requires constant mixing for uniform results, the added mechanical complexity and cost of a rotary tube furnace become necessary.

Material Limitations

The material of the chamber or tube (e.g., quartz vs. alumina) dictates the furnace's maximum operating temperature and its chemical compatibility. Quartz is excellent for visibility and lower temperatures, while alumina is required for higher temperatures but is opaque.

Making the Right Choice for Your Application

Selecting the correct furnace configuration is essential for achieving your desired experimental or production outcomes.

- If your primary focus is general-purpose heating, ashing, or annealing in air: A standard Muffle Furnace provides the simplest and most cost-effective solution.

- If your primary focus is processing samples in an inert gas, a vacuum, or a reactive atmosphere: A Tube Furnace is the necessary choice for precise atmospheric control.

- If your primary focus is ensuring uniform heat treatment and mixing of powders or granules: A Rotary Tube Furnace is required to achieve the necessary material agitation.

Ultimately, understanding the function of each component empowers you to select the right tool for the job.

Summary Table:

| Component | Function | Common Materials/Features |

|---|---|---|

| Heating Chamber | Contains sample and provides uniform thermal environment | Refractory bricks, ceramic fiber |

| Heating Elements | Generate heat for temperature control | Kanthal wire, SiC, MoSi2 |

| Temperature Control System | Regulates and monitors temperature | PID controllers, thermocouples |

| Insulation and Housing | Minimizes heat loss and ensures safety | Multi-layered insulation, metal housing |

| Specialized Components (e.g., Tube, Drive Mechanism) | Enables atmosphere control or material mixing | Quartz/alumina tubes, gas systems, motors |

Need a custom high-temperature furnace for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet your unique experimental requirements. Contact us today to enhance your materials processing efficiency!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- How do you prevent maintenance on a muffle furnace? Extend Lifespan with Proactive Care

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production