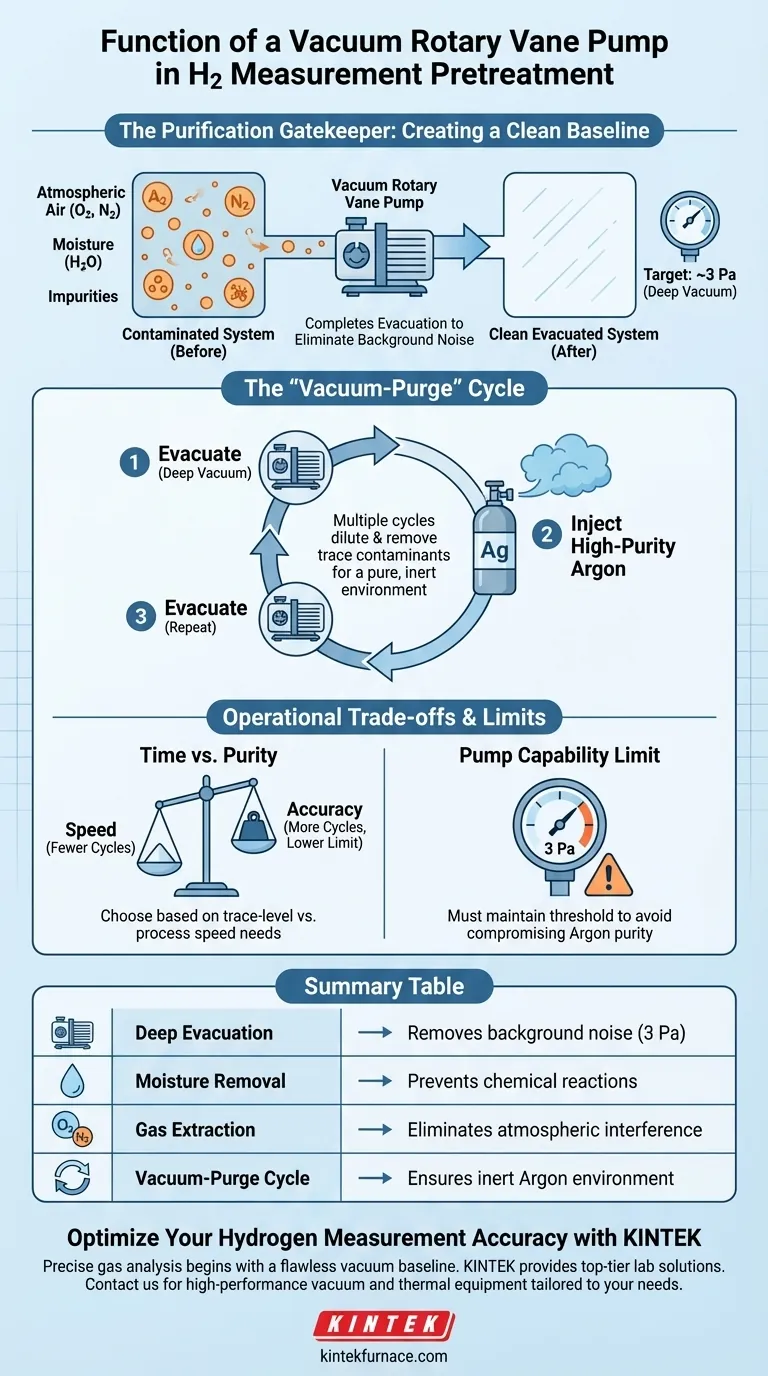

In the pretreatment phase of a hydrogen measurement system, the vacuum rotary vane pump serves a critical function: the complete evacuation of atmospheric air from experimental piping and the autoclave. Its primary role is to drive the system down to extremely low residual pressures—typically around 3 Pa—to physically remove oxygen and moisture before the testing environment is established.

The pump acts as a purification gatekeeper, utilizing multiple vacuum cycles to eliminate background impurities. This ensures that subsequent low-concentration hydrogen detection measures the sample accurately, rather than reacting to residual atmospheric oxygen or water vapor.

Creating a Baseline for Precision

Removal of Interfering Gases

The primary enemy of accurate hydrogen detection is atmospheric contamination. The rotary vane pump operates to extract non-condensable gases, specifically targeting oxygen and nitrogen found in ambient air.

If left in the piping or autoclave, these elements effectively act as "noise," creating a contaminated background that obscures measurement data.

Eliminating Moisture

Beyond simple air extraction, the pump is essential for removing moisture (water vapor). Moisture is particularly detrimental in high-purity gas applications because it can react chemically or adsorb onto surfaces.

By lowering the pressure significantly, the pump forces moisture out of the system, ensuring the experimental volume is dry.

Achieving Deep Vacuum

Standard venting or flushing is insufficient for high-sensitivity measurements. The pump is tasked with reaching a specific residual pressure target, often as low as 3 Pa.

At this pressure level, the density of remaining gas molecules is sufficiently low to prevent significant interference with the sensors.

The Cycling Process

Preparing for Inert Gas Injection

Vacuum generation is not a standalone step; it is the precursor to creating a controlled atmosphere. The pump clears the stage so that high-purity argon can be introduced without dilution.

If argon were introduced without this deep vacuum step, it would simply mix with existing air, failing to create the necessary inert background.

The "Vacuum-Purge" Cycle

To ensure thorough cleaning, the pump is often used in multiple vacuum cycles.

The system is evacuated, filled with argon, and then evacuated again. This repetitive process dilutes and removes even trace contaminants that might adhere to pipe walls.

Understanding the Operational Requirements

The Trade-off of Time vs. Purity

Achieving a residual pressure of 3 Pa takes time and mechanical effort. The process of performing multiple vacuum cycles extends the pretreatment phase significantly compared to a single evacuation.

However, skipping cycles to save time introduces the risk of measurement artifacts, particularly when detecting low-concentration hydrogen.

Pump Capability Limits

The rotary vane pump is specifically chosen for its ability to handle the continuous extraction of air and non-condensables.

However, users must recognize that the pump is limited by its ultimate pressure capability. If the pump cannot consistently maintain the 3 Pa threshold, the purity of the argon environment will be compromised, rendering the resulting hydrogen data unreliable.

Ensuring Measurement Integrity

To apply this to your specific project, evaluate your accuracy requirements against your setup procedures.

- If your primary focus is trace-level detection: You must strictly adhere to the 3 Pa pressure target and employ multiple vacuum cycles to eliminate all oxygen interference.

- If your primary focus is process speed: You must determine the maximum allowable impurity level and verify if fewer vacuum cycles can still achieve a baseline that does not distort your specific sensor readings.

Ultimately, the rotary vane pump transforms the autoclave from a simple container into a precision instrument capable of isolating hydrogen behavior without atmospheric distortion.

Summary Table:

| Feature | Function in Pretreatment | Impact on Measurement |

|---|---|---|

| Deep Evacuation | Reaches residual pressure of ~3 Pa | Removes background 'noise' for sensors |

| Moisture Removal | Extracts water vapor from piping/autoclave | Prevents chemical reactions and adsorption |

| Gas Extraction | Targets non-condensable gases (O2/N2) | Eliminates atmospheric interference |

| Vacuum-Purge Cycle | Prepares system for high-purity Argon | Ensures inert environment without dilution |

Optimize Your Hydrogen Measurement Accuracy with KINTEK

Precise gas analysis begins with a flawless vacuum baseline. KINTEK provides top-tier lab solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, all designed to meet the rigorous demands of modern research. Backed by expert R&D and precision manufacturing, our high-temperature furnaces and vacuum systems can be fully customized to your unique experimental needs.

Don't let atmospheric contamination compromise your data. Contact KINTEK today to discover how our high-performance vacuum and thermal equipment can enhance your laboratory's efficiency and accuracy.

Visual Guide

References

- Measurement of Low-Concentration Hydrogen in Inert Gas Within a Small Closed Volume. DOI: 10.3390/s25123771

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the function of laboratory pellet presses and steel dies? Maximize Reaction Kinetics in Oxide Processing

- What is the function of high-purity graphite molds during SPS of Cu2Se? Essential Tips for Superior Sintering

- What is the function of a water-cooled copper crucible? Master High-Purity Alloy Synthesis with KINTEK

- How do quartz crucibles and quartz cover plates protect the substrate? Optimize TiO2 Nanowire Growth

- Why are high-purity MgO crucibles used for PbO oxidation? Essential Chemical Inertness for Master Slags

- What safety and environmental roles do lab exhaust and flare systems play in pyrolysis? Ensure a Secure Lab Workspace

- How does the gas control system regulate the plasma nitriding process? Master Your N2/H2 Mixture for Superior Surfaces

- What is the function of the nitrogen environment in pyrolysis? Mastering Carbonization with Laboratory Furnaces