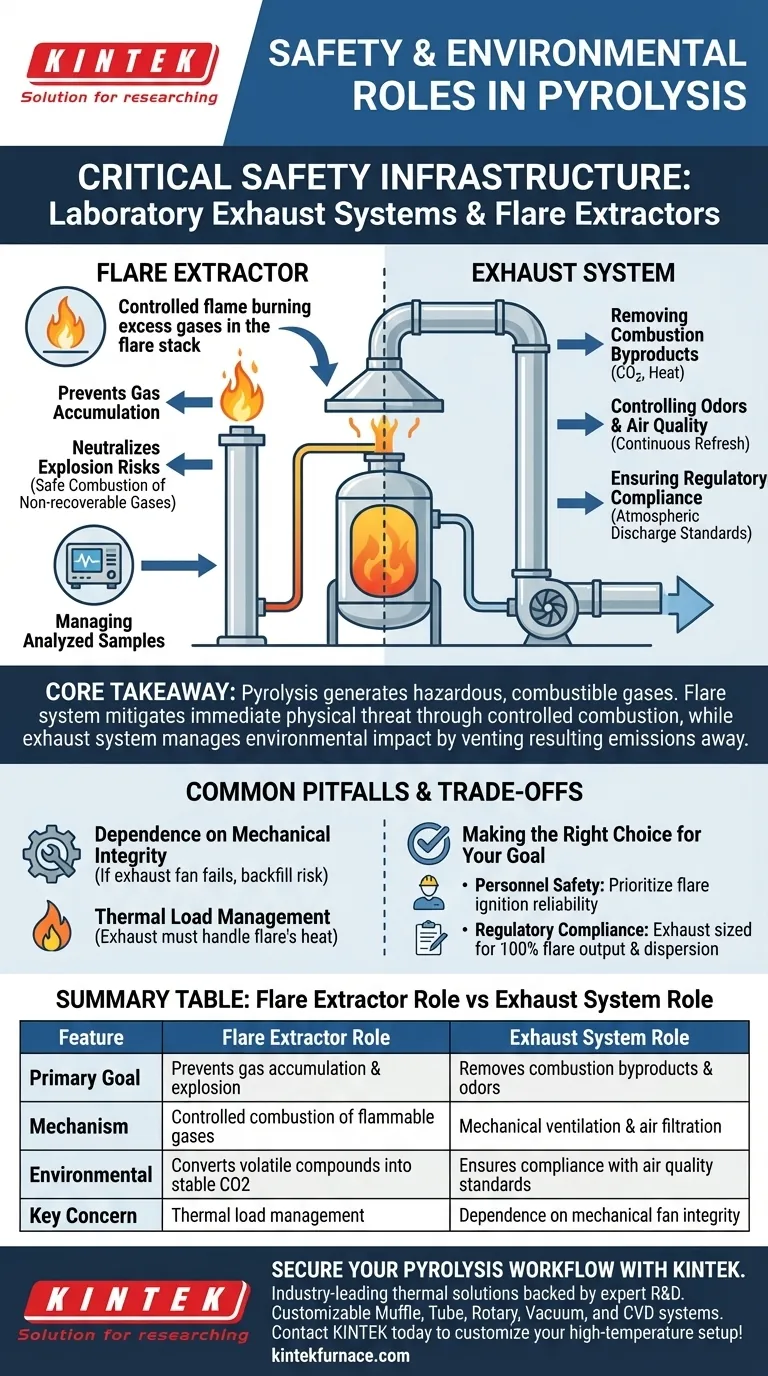

Laboratory exhaust systems and flare extractors act as the critical safety infrastructure for managing the volatile byproducts of pyrolysis. While the flare extractor neutralizes explosion risks by combusting excess flammable gases, the laboratory exhaust system actively removes the resulting fumes and odors to maintain breathable air quality and regulatory compliance.

Core Takeaway Pyrolysis inherently generates hazardous, combustible gases that must never accumulate in a confined space. The flare system mitigates this immediate physical threat through controlled combustion, while the exhaust system manages the environmental impact by venting the resulting emissions away from the workspace.

The Critical Role of Flare Extractors

Preventing Gas Accumulation

In pyrolysis, not all gases produced can be condensed or analyzed. Flare extractors provide a controlled outlet for these residual gases. Without this mechanism, flammable gases would accumulate within the laboratory, creating a dangerous environment ripe for ignition.

Neutralizing Explosion Risks

The primary function of the flare is the safe combustion of non-recoverable gases. By burning these components immediately rather than venting them raw, the system chemically converts highly volatile compounds into stable combustion products, effectively neutralizing the risk of explosion.

Managing Analyzed Samples

Once a gas sample has passed through analytical equipment, it cannot simply be released into the room. The flare system serves as the final destination for these analyzed streams, ensuring that even small quantities of test gas are disposed of safely.

Environmental Control via Exhaust Systems

Removing Combustion Byproducts

While the flare neutralizes flammability, the burning process creates its own byproducts, such as carbon dioxide and heat. The exhaust system captures these post-combustion emissions, ensuring they do not linger in the laboratory or compromise the air supply.

Controlling Odors and Air Quality

Pyrolysis byproducts often carry strong, distinctive, and potentially noxious odors. A properly functioning exhaust system continually refreshes the air volume, removing these residual odors to maintain a comfortable and safe working environment for personnel.

Ensuring Regulatory Compliance

Laboratories are subject to strict environmental discharge regulations regarding what can be released into the atmosphere. The exhaust system ensures that emissions are funneled to appropriate discharge points, keeping the facility compliant with environmental safety standards.

Common Pitfalls and Trade-offs

Dependence on Mechanical Integrity

These systems rely heavily on active mechanical ventilation. If the exhaust fan fails while the flare is active, combustion products can rapidly backfill the laboratory. Redundant safety sensors are often required to shut down the pyrolysis process if airflow is lost.

Thermal Load Management

Flare extractors generate significant heat during combustion. The exhaust system must be rated to handle not just the chemical byproducts, but also the thermal load produced by the flare to prevent damage to ducting or surrounding equipment.

Making the Right Choice for Your Goal

- If your primary focus is Personnel Safety: Prioritize a flare system with robust ignition reliability to ensure no flammable gas ever escapes unburnt.

- If your primary focus is Regulatory Compliance: Ensure your exhaust system is sized to capture 100% of the flare's output and effectively disperse emissions according to local environmental codes.

Effective pyrolysis safety requires a seamless integration where the flare destroys the immediate danger, and the exhaust removes the aftermath.

Summary Table:

| Feature | Flare Extractor Role | Exhaust System Role |

|---|---|---|

| Primary Goal | Prevents gas accumulation & explosion | Removes combustion byproducts & odors |

| Mechanism | Controlled combustion of flammable gases | Mechanical ventilation and air filtration |

| Environmental | Converts volatile compounds into stable CO2 | Ensures compliance with air quality standards |

| Key Concern | Thermal load management | Dependence on mechanical fan integrity |

Secure Your Pyrolysis Workflow with KINTEK

Don't compromise on safety or compliance. KINTEK provides industry-leading thermal solutions backed by expert R&D and manufacturing. Our extensive range includes Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which are customizable to integrate seamlessly with your specific safety protocols. Whether you need to manage volatile byproducts or optimize thermal loads, our high-temp furnaces are built for the rigors of modern research.

Contact KINTEK today to customize your high-temperature setup!

Visual Guide

References

- Zsolt Dobó, Gábor Nagy. Production of Biochar by Pyrolysis of Food Waste Blends for Negative Carbon Dioxide Emission. DOI: 10.3390/en18010144

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is a stainless steel crucible selected for melting AM60 magnesium alloy? Ensure Alloy Purity and Safety

- What are the advantages of using graphite for Sb2S3 sulfurization? Enhancing Thermal Precision and Safety

- How does an in-situ reaction chamber in HTXRD facilitate BiFeO3 synthesis study? Mapping Real-Time Phase Evolution

- Why is a high-performance vacuum pumping system necessary for industrial alloys? Ensure Purity & Peak Performance

- How does a precision Mass Flow Controller (MFC) regulate argon carrier gas to affect the growth of WS2 nanosheets?

- What is the primary function of a high-purity vacuum-sealed quartz tube in the Modified Bridgman technique? Key Role

- How does a laboratory blast drying oven facilitate the treatment of Au/ZnO/In2O3 precursor precipitates? Key Benefits

- What mechanical properties should be evaluated for alumina ceramic furnace tubes? Ensure Durability and Performance