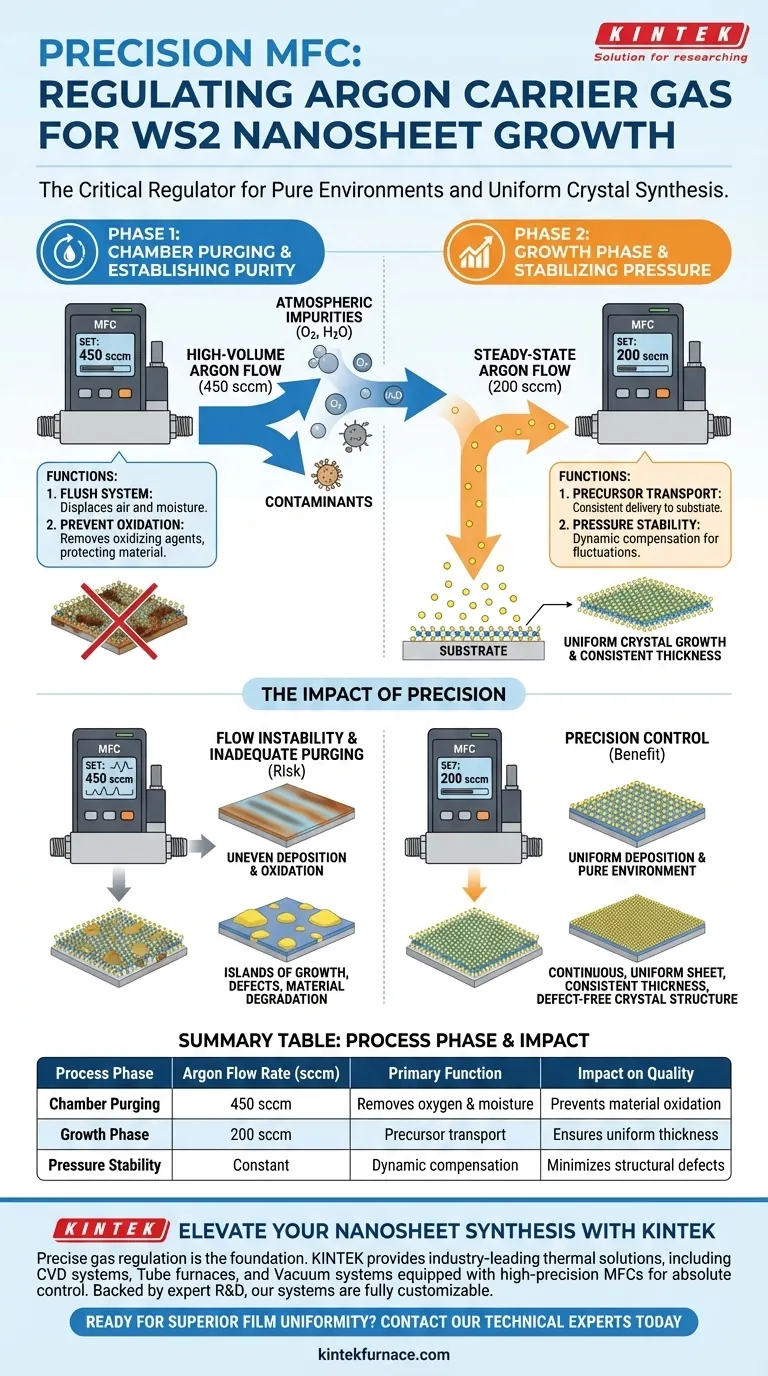

A precision Mass Flow Controller (MFC) acts as the critical regulator in the synthesis of tungsten disulfide (WS2) nanosheets. It strictly manages the flow rate of argon carrier gas to strip the environment of atmospheric contaminants and establish the stable pressure required for uniform crystal growth.

By dynamically adjusting between high-volume purging and steady-state growth flows, the MFC creates a controlled atmosphere. This precision is the defining factor in achieving consistent nanosheet thickness and preventing material degradation through oxidation.

Establishing a Pure Reaction Environment

Purging Atmospheric Impurities

Before growth begins, the reaction chamber must be cleared of air. The MFC regulates a high flow rate of argon—specifically 450 sccm—to flush the system.

Preventing Material Oxidation

This purging process is essential for displacing oxygen and moisture.

By removing these contaminants, the MFC prevents the WS2 material from oxidizing, which would otherwise degrade its electronic properties and structural integrity.

Regulating the Growth Phase

Maintaining Precursor Concentrations

Once the environment is pure, the MFC reduces the argon flow to a specific growth rate, such as 200 sccm.

This steady flow ensures that the chemical precursors are transported to the substrate at a constant, predictable rate.

Stabilizing Reaction Pressure

The quality of nanosheet growth relies heavily on constant pressure within the chamber.

The MFC compensates for any fluctuations, maintaining a stable pressure equilibrium that allows the nanosheets to form without structural defects.

The Impact on Material Quality

Ensuring Surface Uniformity

A fluctuating gas flow results in uneven deposition.

By locking in the flow rate, the MFC ensures that the argon carrier gas distributes the precursor material evenly across the entire substrate surface.

Achieving Consistent Thickness

The thickness of a nanosheet is determined by how much material is deposited over time.

Precision control allows researchers to replicate exact thickness levels in every run, a requirement for scalable device fabrication.

Understanding the Trade-offs

The Consequence of Flow Instability

If the MFC fails to maintain the strict 200 sccm setpoint during growth, the local concentration of precursors will vary.

This leads to uneven film thickness, resulting in "islands" of growth rather than a continuous, uniform sheet.

Risks of Inadequate Purging

Reducing the purge flow below 450 sccm or shortening the purge duration to save gas is a common error.

This often leaves residual oxygen in the chamber, leading to immediate contamination and poor crystal quality regardless of how precise the subsequent growth phase is.

Optimizing Your Deposition Process

To achieve high-quality WS2 nanosheets, you must align your MFC settings with your specific fabrication goals:

- If your primary focus is defect-free crystal structure: Prioritize a rigorous, high-flow purge cycle (450 sccm) to eliminate all traces of oxidizing agents.

- If your primary focus is layer-to-layer consistency: Focus on the stability of the lower-flow growth stage (200 sccm) to ensure uniform precursor delivery.

Mastering the transition between these two flow regimes is the key to reproducible nanosheet synthesis.

Summary Table:

| Process Phase | Argon Flow Rate (sccm) | Primary Function | Impact on Quality |

|---|---|---|---|

| Chamber Purging | 450 sccm | Removes oxygen & moisture | Prevents material oxidation |

| Growth Phase | 200 sccm | Precursor transport | Ensures uniform thickness |

| Pressure Stability | Constant | Dynamic compensation | Minimizes structural defects |

Elevate Your Nanosheet Synthesis with KINTEK

Precise gas regulation is the foundation of high-performance 2D materials. KINTEK provides industry-leading thermal solutions, including CVD systems, Tube furnaces, and Vacuum systems equipped with high-precision MFCs to give you absolute control over your growth environment. Backed by expert R&D and manufacturing, our systems are fully customizable to meet your unique research or production needs.

Ready to achieve superior film uniformity? Contact our technical experts today to find the perfect lab high-temp furnace for your WS2 development.

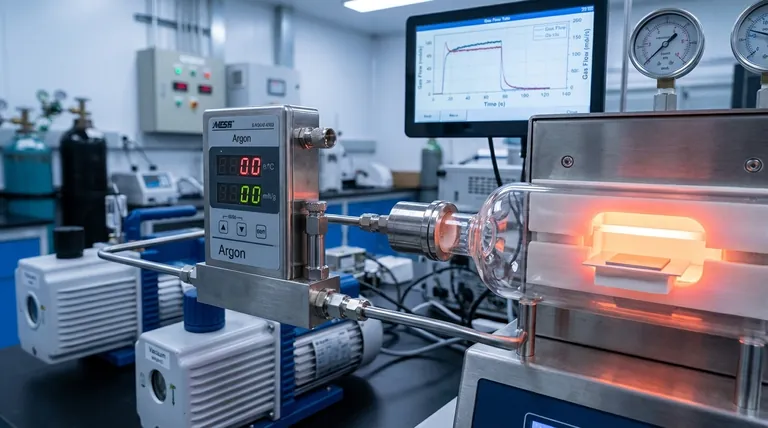

Visual Guide

References

- Mohammad Shahbazi, Ramin Mohammadkhani. High performance in the DC sputtering-fabricated Au/WS2 optoelectronic device. DOI: 10.1038/s41598-025-87873-0

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

- Ultra High Vacuum Observation Window KF Flange 304 Stainless Steel High Borosilicate Glass Sight Glass

People Also Ask

- Why is a sealing lid necessary for the clay-graphite crucible? Key to Successful Fe3O4/C Composite Synthesis

- What are the advantages of nickel crucibles for KOH activation? Ensure High Purity & Thermal Stability up to 700°C

- Why Use a Capped Alumina Crucible for Glycine Pyrolysis? Optimize Your Carbon-Based Composite Synthesis

- What are the advantages of water circulating vacuum pumps? Discover Oil-Free, Reliable Solutions for Clean Processes

- What are the advantages of using a laboratory vacuum drying oven for modified ZnO nanomaterials? Protect Nano-Integrity

- Why is a vacuum pump utilized in research concerning the reaction of magnesium with carbon dioxide and nitrogen? Ensure Data Integrity

- Why is a quartz tube selected as the sample container for emissivity measurement? Precision Microwave Heating Benefits

- Why is a Boron Nitride (BN) crucible ideal for high-temp graphite catalyst treatment? Ensure Purity & Sample Integrity