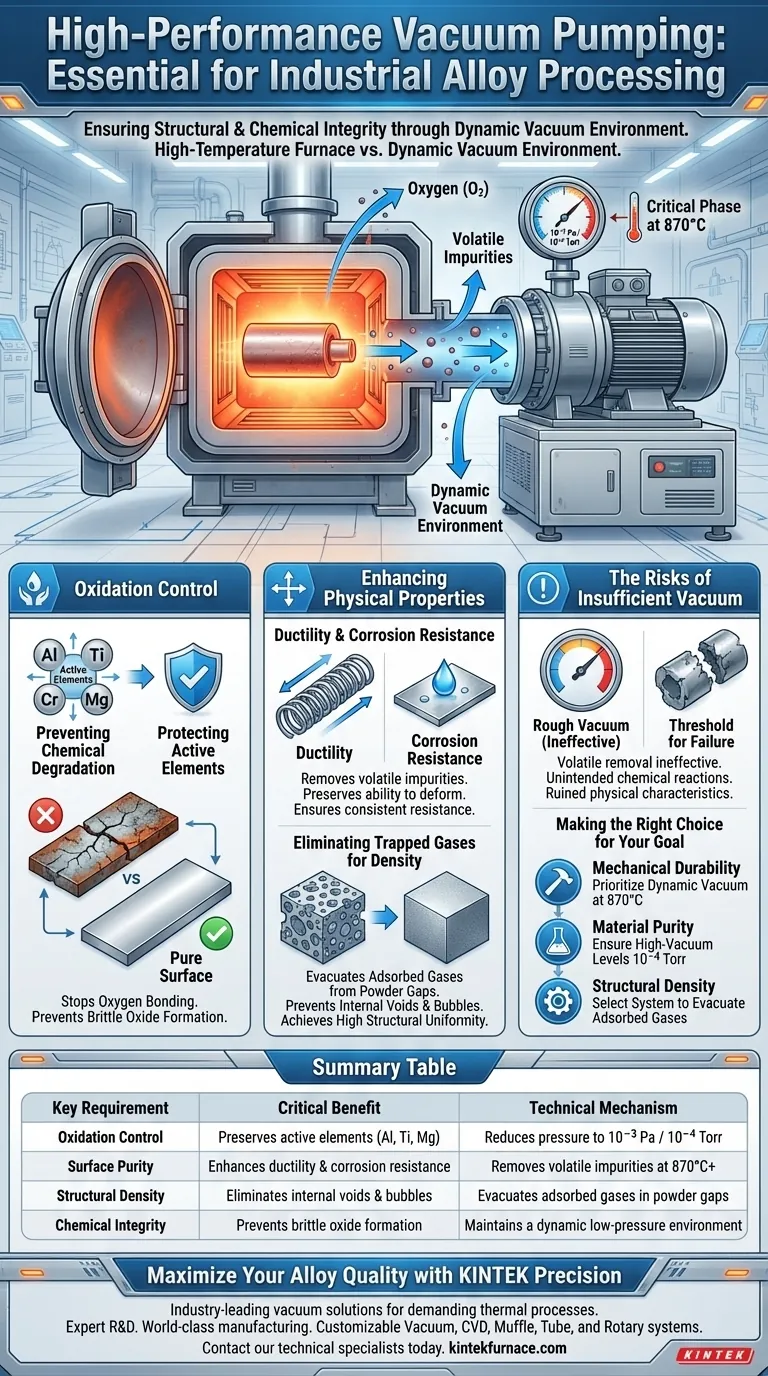

A high-performance vacuum pumping system is indispensable for ensuring the structural and chemical integrity of industrial alloys during processing. Its immediate function is to generate a low-pressure environment that prevents oxidation and actively removes contaminants, which is the only way to guarantee the material performs as intended after exposure to extreme heat.

The core function of these systems is to establish a "dynamic vacuum environment." This actively strips away residual oxygen and volatile impurities from the alloy's surface, particularly during critical thermal phases around 870°C. Without this intervention, essential mechanical properties like ductility and corrosion resistance are inevitably compromised.

The Critical Role of Oxidation Control

Preventing Chemical Degradation

The primary threat to alloy integrity during melting and heat treatment is oxygen. When alloys are heated, they become highly reactive.

A high-performance vacuum system reduces the internal pressure to extremely low levels (often between 10^-3 Pa and 10^-4 Torr). This is necessary to stop oxygen from bonding with the metal.

Protecting Active Elements

Many advanced alloys contain "active" elements such as aluminum, titanium, chromium, or magnesium. These elements have a high affinity for oxygen.

Without a vacuum, these components will rapidly oxidize or "burn" at high temperatures. The pumping system ensures these elements remain part of the alloy matrix rather than turning into brittle oxides.

Enhancing Physical Properties

Ensuring Ductility and Corrosion Resistance

The primary reference highlights that the removal of impurities is directly linked to the final performance of the alloy.

By removing volatile impurities from the surface, the vacuum process preserves the alloy's ductility (its ability to deform without breaking). Furthermore, a pure surface is essential for establishing consistent corrosion resistance in the finished part.

Eliminating Trapped Gases for Density

Beyond surface chemistry, vacuum systems address internal structural issues. In processes like powder sintering or hot isostatic pressing, gases can get trapped in the gaps between particles.

The vacuum system evacuates these adsorbed gases and residual air. This prevents the formation of internal bubbles or voids, ensuring the final product achieves high density and structural uniformity.

Understanding the Risks of Insufficient Vacuum

The Threshold for Failure

The requirement for a "high-performance" system is not arbitrary; it is a strict technical threshold. Achieving a rough vacuum is often insufficient for advanced alloys.

If the system fails to reach specific high-vacuum levels (e.g., 10^-4 Torr or better), volatile removal becomes ineffective. This results in unintended chemical reactions, such as the oxidation of sulfur or selenium in semiconductor materials, which ruins the physical characteristics of the product.

Making the Right Choice for Your Goal

The specific requirements of your vacuum system should be dictated by the material properties you value most.

- If your primary focus is Mechanical Durability: Prioritize a system capable of sustaining a dynamic vacuum at 870°C to ensure ductility and corrosion resistance.

- If your primary focus is Material Purity: Ensure the system can reach high-vacuum levels (10^-4 Torr range) to prevent the oxidation of active elements like magnesium or titanium.

- If your primary focus is Structural Density: Select a system designed to evacuate adsorbed gases from powder gaps to prevent internal voids and bubbles.

Reliable alloy performance is impossible without the precise environmental control provided by high-performance vacuum pumping.

Summary Table:

| Key Requirement | Critical Benefit | Technical Mechanism |

|---|---|---|

| Oxidation Control | Preserves active elements (Al, Ti, Mg) | Reduces pressure to 10^-3 Pa / 10^-4 Torr |

| Surface Purity | Enhances ductility & corrosion resistance | Removes volatile impurities at 870°C+ |

| Structural Density | Eliminates internal voids & bubbles | Evacuates adsorbed gases in powder gaps |

| Chemical Integrity | Prevents brittle oxide formation | Maintains a dynamic low-pressure environment |

Maximize Your Alloy Quality with KINTEK Precision

Don't let oxidation or internal voids compromise your critical components. KINTEK provides industry-leading vacuum solutions tailored for the most demanding thermal processes. Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of lab high-temperature furnaces—including Vacuum, CVD, Muffle, Tube, and Rotary systems—all of which are fully customizable to meet your specific pressure and temperature thresholds.

Ensure your materials achieve the structural uniformity and chemical purity they require. Contact our technical specialists today to find the perfect high-performance system for your lab or production line.

Visual Guide

References

- Yu. H. Kvasnytska, K. H. Kvasnytska. Influence of Refractory Elements on Phase–Structural Stability of Heat-Resistant Corrosion-Resistant Alloys for Gas Turbine Blades. DOI: 10.15407/mfint.45.08.0975

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- Why are quartz tubes indispensable in advanced technologies? Unlock Purity and Performance

- How does the impeller in a water circulating vacuum pump function to create a vacuum? Discover the Liquid Piston Mechanism

- What is the specific significance of using high-purity corundum crucibles in oxidation weight gain experiments?

- Why are graphite crucible furnaces used in vacuum or protective atmosphere environments? Prevent Oxidation and Ensure Purity

- How does insulation affect laboratory furnace design? Optimize Thermal Performance and Safety

- Why are fume hoods and sealed quartz tubes mandatory for BiF3 and SbF3? Safety in High-Temp Fluoride Reactions

- Why is the use of high-alumina crucibles essential for NCM811? Ensure Purity in High-Nickel Cathode Synthesis

- What are the advantages of using alumina (Al2O3) crucibles for the high-temperature pyrolysis of Bakelite?