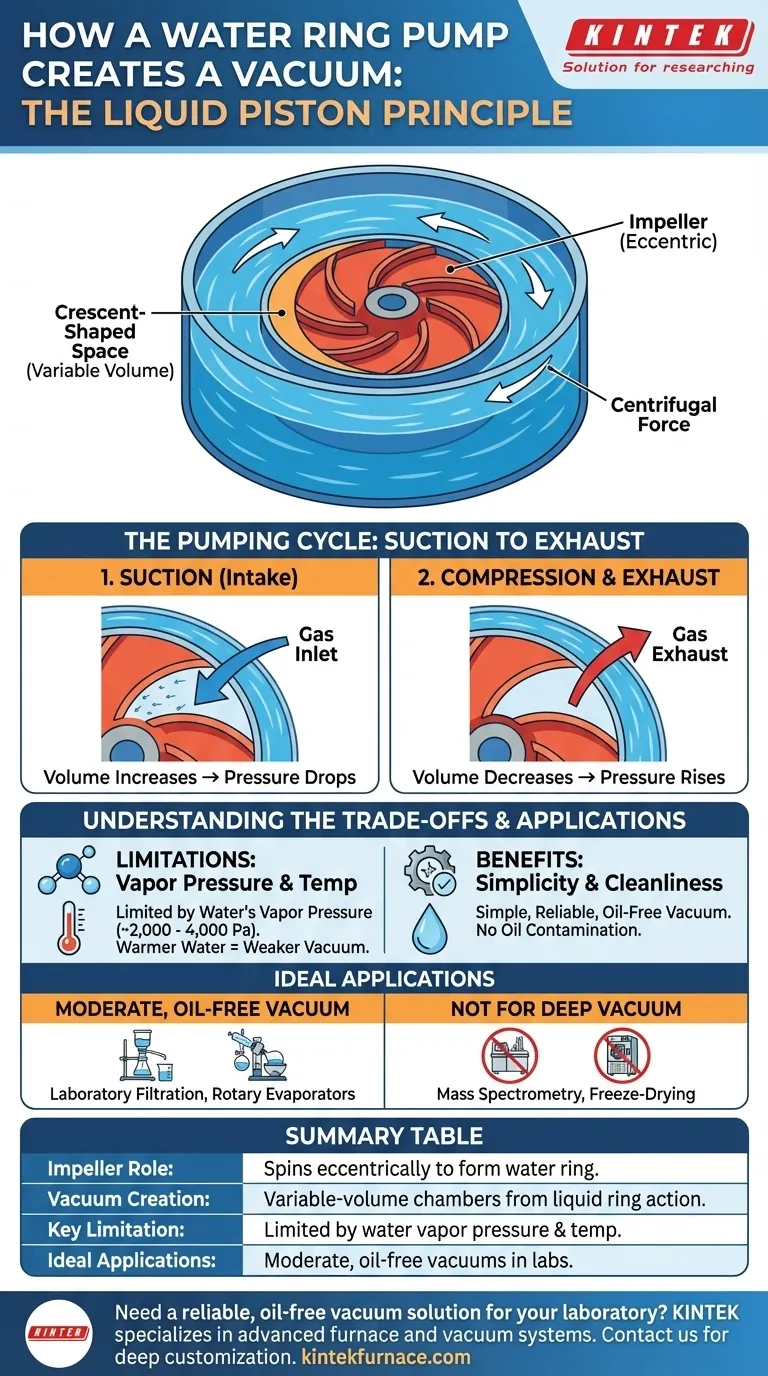

The impeller in a water circulating vacuum pump creates a vacuum indirectly. It does not move gas itself, but instead uses centrifugal force to spin a captive ring of water against the pump's outer casing. Because the impeller is mounted off-center, the space between its blades and this water ring constantly expands and contracts, creating low-pressure zones that suck gas in and high-pressure zones that push it out.

The key to the entire process is the eccentric (off-center) placement of the impeller within the pump casing. This geometry forces the formation of a crescent-shaped void between the impeller hub and the water ring, which is the engine of the vacuum action.

The Core Principle: The Liquid Piston

A water ring pump is a type of rotary positive displacement pump. Its genius lies in using a simple, readily available liquid—water—to act as a series of moving pistons.

Creating the Liquid Ring

When the pump is turned on, the impeller spins rapidly. This rotation flings the water inside the pump outwards against the cylindrical casing due to centrifugal force. This forms a stable, concentric ring of liquid that follows the shape of the casing.

The Critical Role of Eccentricity

The impeller is not mounted in the center of the cylindrical casing; it is mounted eccentrically. This means the impeller hub is closer to the casing wall at one point (e.g., the bottom) and farthest from it at another (e.g., the top).

This off-center arrangement is what creates a crescent-shaped space between the impeller hub and the inner surface of the liquid ring.

The 'Liquid Piston' in Action

The blades of the impeller divide this crescent-shaped space into a series of small chambers or "cells." As the impeller rotates, each cell's volume changes dramatically.

The inner wall of the water ring effectively acts as a liquid cylinder head, while the impeller blades act as pistons moving back and forth within it.

The Pumping Cycle: Suction to Exhaust

The entire vacuum process happens in a continuous, smooth rotation.

-

Suction (Intake): As a chamber rotates away from the closest point to the casing, the water ring recedes. The volume within that chamber increases, causing a drop in pressure. This creates the vacuum that draws gas in through the inlet port.

-

Compression and Exhaust: As that same chamber continues its rotation towards the closest point, the water ring advances. The volume within the chamber decreases, compressing the trapped gas. This high-pressure gas is then forced out through the exhaust port.

Understanding the Trade-offs

While elegant in its simplicity, the design of a water ring pump has inherent limitations you must understand.

The Vapor Pressure Limitation

The ultimate vacuum a pump can achieve is limited by the saturated vapor pressure of its working fluid. Water has a relatively high vapor pressure compared to specialized vacuum oils.

This means that at a certain low pressure, the water itself will begin to boil, filling the vacuum with water vapor and preventing the pressure from dropping any further. Typically, a water ring pump is limited to a vacuum of 2,000 to 4,000 Pa. In contrast, an oil-sealed pump can reach pressures as low as 130 Pa or less.

The Impact of Water Temperature

Vapor pressure is highly dependent on temperature. Warmer water has a higher vapor pressure, which means it will boil at a higher pressure (a weaker vacuum).

For this reason, the performance of a water ring pump degrades as the circulating water heats up. Using cold water is critical for achieving the best possible vacuum.

The Benefit: Simplicity and Cleanliness

The primary trade-off for this limited vacuum depth is immense practical benefit. These pumps are mechanically simple, reliable, and produce a clean, oil-free vacuum. This makes them ideal for applications where oil contamination would be a problem.

Making the Right Choice for Your Application

Understanding this mechanism allows you to select the correct pump for your specific goal.

- If your primary focus is a moderate, clean vacuum (e.g., laboratory filtration, rotary evaporators): A water circulating pump is an excellent, low-maintenance choice due to its simplicity and oil-free operation.

- If your primary focus is achieving a deep or high vacuum (e.g., mass spectrometry, freeze-drying): You must use a technology like an oil-sealed rotary vane pump, as a water ring pump cannot physically reach the required low pressures.

By grasping the principle of the liquid ring, you can effectively leverage its strengths while respecting its fundamental limitations.

Summary Table:

| Function | Description |

|---|---|

| Impeller Role | Spins eccentrically to form a water ring via centrifugal force, creating variable-volume chambers. |

| Vacuum Creation | Chambers expand to suck in gas (suction) and compress to exhaust it, driven by the liquid ring. |

| Key Limitation | Limited by water's vapor pressure, achieving vacuums of 2,000-4,000 Pa; performance depends on water temperature. |

| Ideal Applications | Best for moderate, oil-free vacuums in labs (e.g., filtration, rotary evaporators); not for deep vacuums. |

Need a reliable, oil-free vacuum solution for your laboratory? KINTEK specializes in advanced high-temperature furnace systems, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs. Contact us today to discuss how our solutions can enhance your lab's efficiency and precision!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is a heating device with magnetic stirring required for Y2O3-MgO precursors? Ensure Perfect Particle Coating

- Why is a laboratory vacuum drying oven necessary for processing nano MOFs? Preserve nLn-bdc Structural Integrity

- Why are high-purity crucibles and sealed reaction environments necessary for NaRu2O4 growth? Ensure Crystal Integrity

- What are the specific functions of a magnetic stirrer and a condenser reflux apparatus in the synthesis of KCC-1? Expert Insights

- What is the specific significance of using high-purity corundum crucibles in oxidation weight gain experiments?

- Why are high-purity alumina crucibles selected as the substrate during the sintering of boron-containing stainless steel?

- What is the primary function of a high-energy planetary ball mill? Unlock Nanoscale Ceramic Pretreatment

- How does a heating stage contribute to the quality of multi-material 3D printing? Optimize Precision and Stability