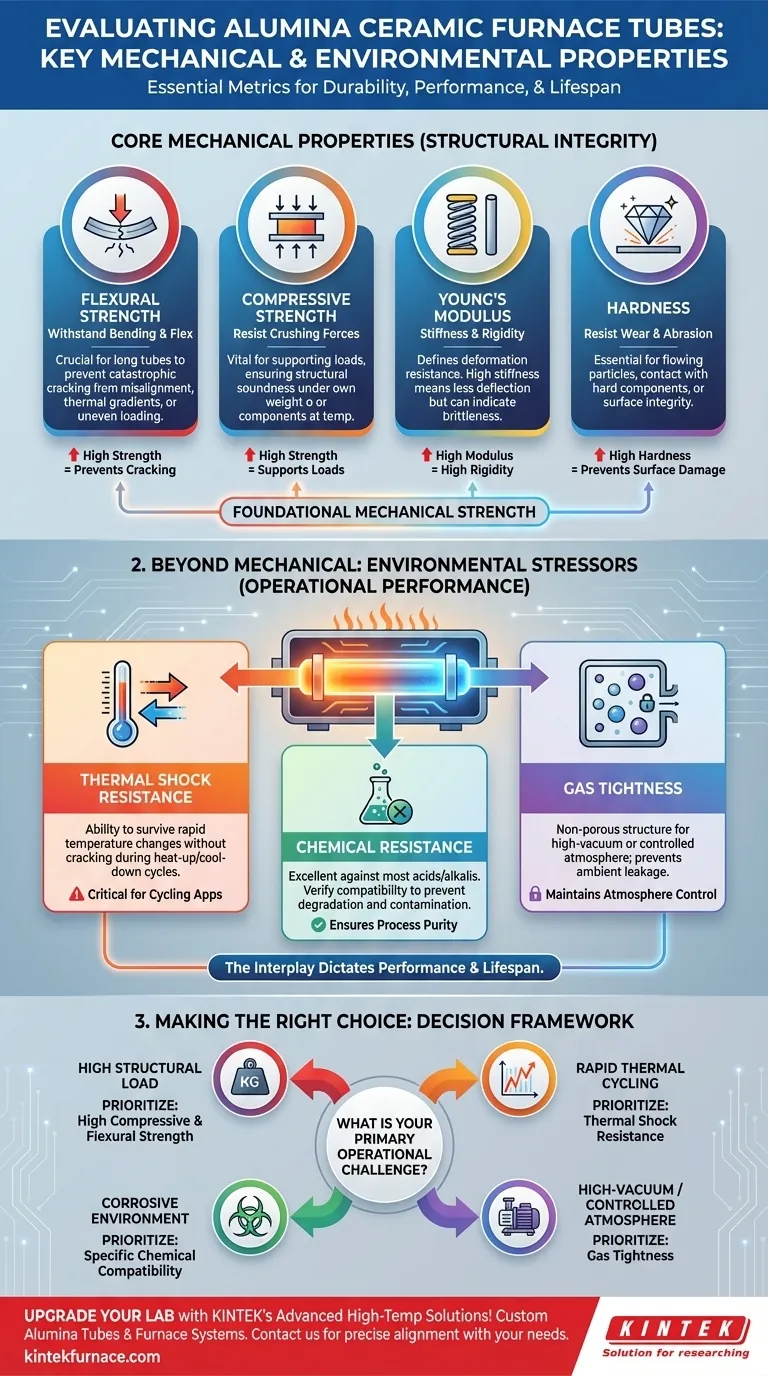

When selecting an alumina ceramic furnace tube, the essential mechanical properties to evaluate are its flexural strength, compressive strength, Young's modulus, and hardness. These metrics collectively define the tube's ability to resist mechanical failure from bending, crushing forces, and surface abrasion under operational stress.

The key to selecting the right furnace tube is understanding that while mechanical properties are foundational, the extreme environment of a furnace demands a broader evaluation. The interplay between mechanical strength, thermal shock resistance, and chemical inertness ultimately dictates the tube's performance and lifespan.

Deconstructing the Core Mechanical Properties

To make an informed decision, you must understand what each mechanical property signifies for real-world performance. These values determine the tube's structural integrity.

Compressive Strength: Resisting Crushing Forces

Compressive strength measures the tube's capacity to withstand forces that attempt to crush or shorten it. This is critical for applications where the tube supports a load or is subject to external pressure.

High compressive strength ensures the tube remains structurally sound and does not fracture under its own weight or the weight of components at extreme temperatures.

Flexural Strength: Withstanding Bending and Flex

Flexural strength, or modulus of rupture, indicates a material's ability to resist deformation and failure under a bending load. This is one of the most important properties for ceramic tubes.

Given their long, thin geometry, furnace tubes are susceptible to bending stress from misalignment, thermal gradients, or uneven loading. High flexural strength prevents catastrophic cracking.

Young's Modulus: Understanding Stiffness and Rigidity

Young's modulus of elasticity defines the material's stiffness. A high modulus means the material is very rigid and will deform very little under load.

While high stiffness is often desirable, it can also correlate with brittleness. It's a measure of rigidity, not ultimate strength, and indicates how much the tube will deflect under a given stress.

Hardness: Resisting Wear and Abrasion

Hardness measures the tube's resistance to localized surface damage, such as scratching or abrasion. Alumina is an exceptionally hard material.

This property is crucial in applications involving flowing particles, contact with other hard components, or processes where surface integrity is paramount to prevent contamination.

Beyond Mechanical: Essential Properties for Furnace Environments

A furnace tube operates in a complex environment where thermal and chemical stresses are just as destructive as mechanical ones. A purely mechanical evaluation is incomplete.

Thermal Shock Resistance: Surviving Rapid Temperature Changes

Thermal shock resistance is the ability to withstand rapid temperature changes without cracking. This is governed by a combination of thermal expansion, thermal conductivity, and flexural strength.

A tube with poor thermal shock resistance can fail during heat-up or cool-down cycles, making this a critical parameter for any application that isn't held at a constant temperature.

Chemical Resistance: Ensuring Integrity in Corrosive Atmospheres

Alumina exhibits excellent resistance to most acids, alkalis, and organic solvents. However, you must verify its compatibility with the specific chemicals in your process.

This property ensures the tube does not degrade or contaminate the process, which is essential in chemical processing, metallurgy, and semiconductor manufacturing.

Gas Tightness: Maintaining Atmosphere Control

High-purity alumina tubes are non-porous and "gas tight." This is a non-negotiable property for high-vacuum applications or processes requiring a controlled, protective atmosphere.

A gas-tight tube prevents ambient air from leaking into the furnace, which could otherwise compromise or ruin the process environment.

Understanding the Trade-offs and Material Nuances

The numbers on a data sheet are only part of the story. The manufacturing process and material purity introduce critical nuances that impact performance.

The Purity vs. Performance Equation

The purity of the alumina (e.g., 99.5% vs. 99.8%) directly affects its properties. Higher purity generally improves chemical resistance and dielectric strength but can sometimes influence mechanical properties and cost.

Why "Typical Values" Are a Starting Point

The values for strength, hardness, and other properties are "typical" for a reason. They can vary between manufacturers based on grain size, sintering processes, and the presence of additives.

Always request a material data sheet for the specific product you are considering, not just a general guide for alumina.

Making the Right Choice for Your Application

Use your primary operational challenge as the lens through which you evaluate material properties.

- If your primary focus is high structural load: Prioritize high compressive and flexural strength to prevent mechanical failure.

- If your primary focus is rapid thermal cycling: Thermal shock resistance is your most critical metric to prevent cracking during heating and cooling.

- If your primary focus is a corrosive chemical environment: Verify specific chemical compatibility above all else to ensure longevity and prevent process contamination.

- If your primary focus is high-vacuum or controlled atmosphere: Gas tightness is non-negotiable to maintain the integrity of your environment.

Choosing the right material by holistically evaluating its properties is the first step toward ensuring the reliability and success of your high-temperature process.

Summary Table:

| Property | Importance for Furnace Tubes |

|---|---|

| Flexural Strength | Resists bending and cracking under load |

| Compressive Strength | Withstands crushing forces and pressure |

| Young's Modulus | Indicates stiffness and rigidity |

| Hardness | Prevents surface wear and abrasion |

| Thermal Shock Resistance | Survives rapid temperature changes |

| Chemical Resistance | Maintains integrity in corrosive environments |

| Gas Tightness | Ensures atmosphere control for vacuum processes |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable alumina ceramic tubes and custom furnace systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing durability, performance, and efficiency. Contact us today to discuss how we can support your high-temperature processes!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety