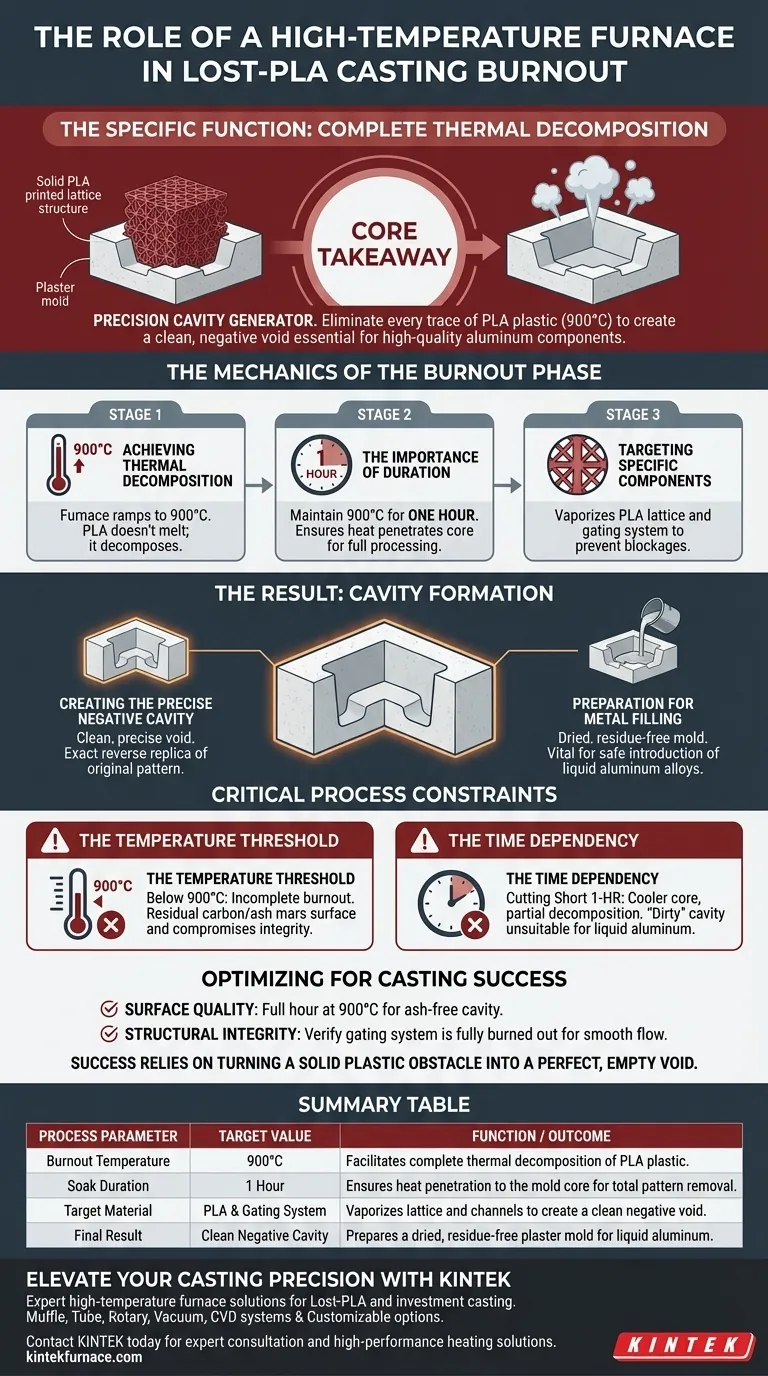

The primary function of a laboratory high-temperature furnace in the Lost-PLA casting process is to facilitate the complete thermal decomposition of the pattern material. By ramping the internal temperature to 900°C and holding it for one hour, the furnace vaporizes the PLA (Polylactic Acid) lattice and gating system inside the plaster mold. This specific heat treatment is the defining step that converts a solid model into a hollow vessel ready for casting.

Core Takeaway The furnace acts as a precision cavity generator, not just a heat source. Its specific role is to eliminate every trace of the PLA plastic through sustained high heat (900°C), leaving behind a clean, negative void essential for high-quality aluminum alloy components.

The Mechanics of the Burnout Phase

The burnout stage is a chemical and physical transformation process driven by precise thermal control.

Achieving Thermal Decomposition

The furnace must reach a critical temperature threshold of 900°C. At this intensity, the PLA plastic does not merely melt; it undergoes decomposition. This ensures the material breaks down completely rather than pooling at the bottom of the mold.

The Importance of Duration

Reaching temperature is not enough; the furnace must maintain 900°C for one hour. This "soak time" ensures heat penetrates the core of the plaster mold. It guarantees that the entire pattern, from the thickest sections to the finest details, is fully processed.

Targeting Specific Components

The heat treatment specifically targets the PLA plastic lattice and the gating system. The lattice represents the structural model, while the gating system creates the channels for liquid metal entry. Both must be removed entirely to prevent blockages.

The Result: Cavity Formation

The ultimate output of the furnace operation is the creation of a "negative" space.

Creating the Precise Negative Cavity

Once the PLA is burned away, what remains is a clean, precise negative cavity. This void creates an exact reverse replica of the original 3D printed pattern. The precision of this cavity dictates the dimensional accuracy of the final part.

Preparation for Metal Filling

The process results in a dried plaster mold free of residues. This dryness and cleanliness are vital conditions for the safe introduction of liquid aluminum alloys. Any remaining plastic or moisture could cause casting defects or dangerous reactions with the molten metal.

Critical Process Constraints

While the process is straightforward, adherence to the specific parameters provided in the reference is non-negotiable for success.

The Temperature Threshold

Operating below 900°C poses a significant risk of incomplete burnout. If the temperature is insufficient, residual carbon or plastic ash may remain in the mold. This residue will mar the surface of the final aluminum cast or compromise its structural integrity.

The Time Dependency

Cutting short the one-hour maintenance period creates a trade-off between throughput and quality. Reducing the time at temperature may leave the core of the mold cooler than the exterior. This leads to partial decomposition and a "dirty" mold cavity that cannot accept liquid aluminum properly.

Optimizing for Casting Success

To ensure the high-temperature furnace effectively enables your Lost-PLA casting, strictly adhere to the established parameters.

- If your primary focus is Surface Quality: Ensure the furnace holds at 900°C for the full hour to guarantee a completely clean, ash-free negative cavity.

- If your primary focus is Structural Integrity: Verify that the gating system is fully burned out so liquid aluminum can flow without turbulence or obstruction.

The success of the entire casting project relies on the furnace's ability to turn a solid plastic obstacle into a perfect, empty void.

Summary Table:

| Process Parameter | Target Value | Function / Outcome |

|---|---|---|

| Burnout Temperature | 900°C | Facilitates complete thermal decomposition of PLA plastic. |

| Soak Duration | 1 Hour | Ensures heat penetration to the mold core for total pattern removal. |

| Target Material | PLA & Gating System | Vaporizes the lattice and channels to create a clean negative void. |

| Final Result | Clean Negative Cavity | Prepares a dried, residue-free plaster mold for liquid aluminum. |

Elevate Your Casting Precision with KINTEK

Don't let residual ash or uneven heating ruin your complex castings. KINTEK provides industry-leading high-temperature furnace solutions designed for the rigorous demands of Lost-PLA and investment casting.

Backed by expert R&D and precision manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need standard lab equipment or a customizable system tailored to your unique thermal profile, KINTEK ensures your materials achieve perfect structural integrity every time.

Ready to optimize your burnout process? Contact KINTEK today for expert consultation and high-performance heating solutions.

Visual Guide

References

- Alessandra Ceci, Maria Elisa Tata. Production of Al Alloys with Kelvin Cells Using the Lost-PLA Technique and Their Mechanical Characterization via Compression Tests. DOI: 10.3390/ma18020296

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the primary function of a high-energy planetary ball mill? Unlock Nanoscale Ceramic Pretreatment

- Why is vacuum sealing in quartz tubes essential for Cr0.82Mn0.18Ge? Ensure Stoichiometry & Purity

- How does a planetary ball mill prepare precursors for furnaces? Unlock Nano-Scale Precision for High-Temp Success

- What role does specialized graphite adhesive play? Expert Bonding Solutions for High-Temp Systems

- What factors affect the light transmittance of alumina tubes? Balance Clarity and Durability for Your Lab

- Why is a high-precision DC power supply necessary for PFS? Control Electric Fields for Perfect Plasma Sintering

- What role does a high-purity quartz tube play in flash Joule heating? Ensure Safety and Process Control

- What role do high-purity graphite molds and punches play during the sintering of silicon carbide ceramics in SPS?