Precise control is the prerequisite for success in Plasma Flash Sintering (PFS). A high-precision DC power supply is necessary to maintain a constant electric field (typically around 300 V cm⁻¹) during the incubation period. This specific stability is required to induce gas ionization and generate the plasma essential for the process to function.

The core function of the power supply extends beyond simple energy delivery; it acts as a dynamic control system. It must sustain a steady electric field to trigger the process, then immediately react to the flash event to prevent catastrophic sample failure.

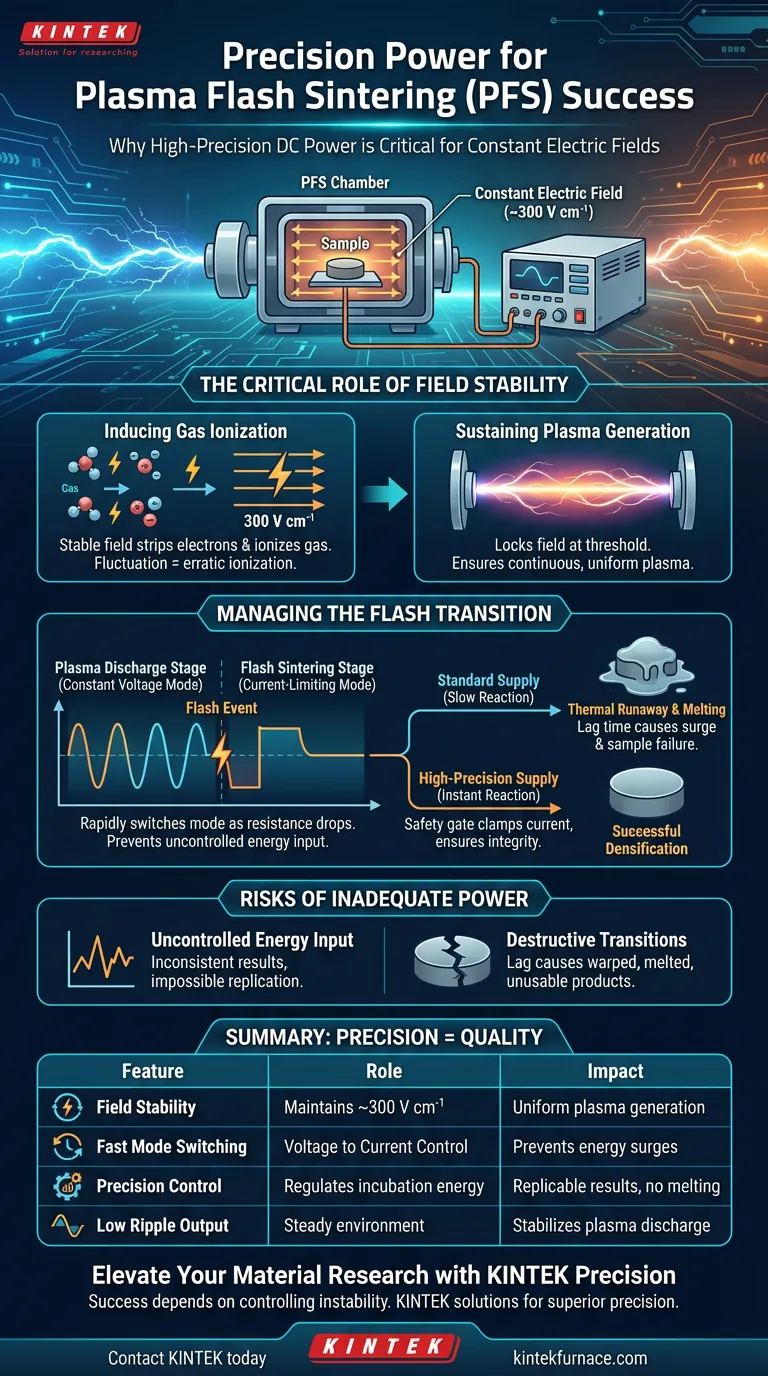

The Critical Role of Field Stability

To understand why high precision is non-negotiable, you must look at the physics occurring during the incubation period.

Inducing Gas Ionization

Before sintering occurs, the system must generate a plasma environment.

A stable electric field is the force that strips electrons and ionizes the gas surrounding the sample. If the power supply allows the voltage to fluctuate, ionization becomes erratic, failing to establish the necessary conditions for the next stage.

Sustaining Plasma Generation

Once ionization begins, the plasma must be sustained.

A high-precision supply locks the electric field at the required threshold (e.g., 300 V cm⁻¹). This consistency ensures that the plasma generation is continuous and uniform, preparing the material for the flash event.

Managing the Flash Transition

The most dangerous moment in PFS is the transition from the plasma discharge stage to the flash sintering stage. This is where the power supply’s capabilities are tested.

rapid Mode Switching

As the system enters the flash state, the electrical resistance of the sample drops precipitously.

The power supply must be capable of rapidly switching from a constant-voltage mode to a current-limiting mode. A standard power supply often cannot react fast enough to this sudden change in load characteristics.

Preventing Sample Melting

If the current is not instantly limited during the flash, the energy input becomes uncontrolled.

This results in thermal runaway, causing the sample to melt rather than sinter. The high-precision supply acts as a safety gate, clamping the current to ensure the material densifies without losing structural integrity.

Risks of Inadequate Power Management

Using a standard or low-precision power supply introduces significant variables that compromise experimental validity and material quality.

Uncontrolled Energy Input

Without precise regulation, the energy delivered to the sample fluctuates.

This inconsistency makes it impossible to replicate results or study the kinetics of the sintering process accurately. You cannot determine if a failure was due to material properties or power variance.

Destructive Transitions

The lag time in switching modes is the primary cause of sample loss.

If the transition to current-limiting mode is delayed even by milliseconds, the surge in current can destroy the sample microstructure. This leads to warped, melted, or unusable final products.

Optimizing Your PFS Configuration

When selecting a power supply for Plasma Flash Sintering, your choice dictates the reliability of your data and the quality of your samples.

- If your primary focus is reliable plasma generation: Prioritize a supply with ultra-low ripple and high voltage stability to maintain the 300 V cm⁻¹ field during incubation.

- If your primary focus is sample integrity: Ensure the supply features a fast-response control loop capable of instantaneous switching to current-limiting mode upon flash ignition.

True precision in PFS is defined by the ability to control instability.

Summary Table:

| Feature | Role in PFS Process | Impact on Material Quality |

|---|---|---|

| Field Stability | Maintains constant electric field (~300 V cm⁻¹) | Ensures uniform gas ionization and plasma generation |

| Fast Mode Switching | Transitions from constant-voltage to current-limiting | Prevents uncontrolled energy surges during the flash event |

| Precision Control | Regulates incubation energy delivery | Guarantees replicable results and prevents sample melting |

| Low Ripple Output | Provides steady electrical environment | Stabilizes the plasma discharge stage for uniform density |

Elevate Your Material Research with KINTEK Precision

Success in Plasma Flash Sintering (PFS) depends on the ability to control instability. At KINTEK, we understand that milliseconds determine the difference between a perfectly densified material and a melted sample. Backed by expert R&D and manufacturing, we provide high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with customizable high-temperature lab furnaces designed to meet your most rigorous power management needs.

Ready to achieve superior precision in your lab? Contact KINTEK today to discuss our customizable furnace solutions and see how our expertise can optimize your sintering outcomes.

Visual Guide

References

- Eva Gil‐González, Luis A. Pérez‐Maqueda. Plasma‐flash sintering: Metastable phase stabilization and evidence of ionized species. DOI: 10.1111/jace.20105

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the risks of using high-purity alumina crucibles for periodate decomposition? Avoid Crucial Data Errors

- How does the choice of high-purity ceramic crucibles impact glass phantoms? Unlock Optical Precision in Sintering

- Why is ultrasonic cleaning with acetone required before thermal oxidation? Ensure Perfect Stainless Steel Adhesion

- What customization options are available for laboratory furnaces? Tailor Your Furnace for Precise Thermal Control

- What is the function of a graphite crucible with a threaded lid? Key to Successful Mg3Sb2 Synthesis

- Why is a U-shaped quartz reactor required for H2-TPR? Ensure Precision for Cu–Ce/HZSM-5 Analysis

- What are the functions of a high vacuum mechanical pump in Ga2O3 PETO? Ensure Purity in Film Preparation

- What role does a quartz substrate holder play in MoS2 growth? Optimize Thin Film Deposition with Precision Hardware