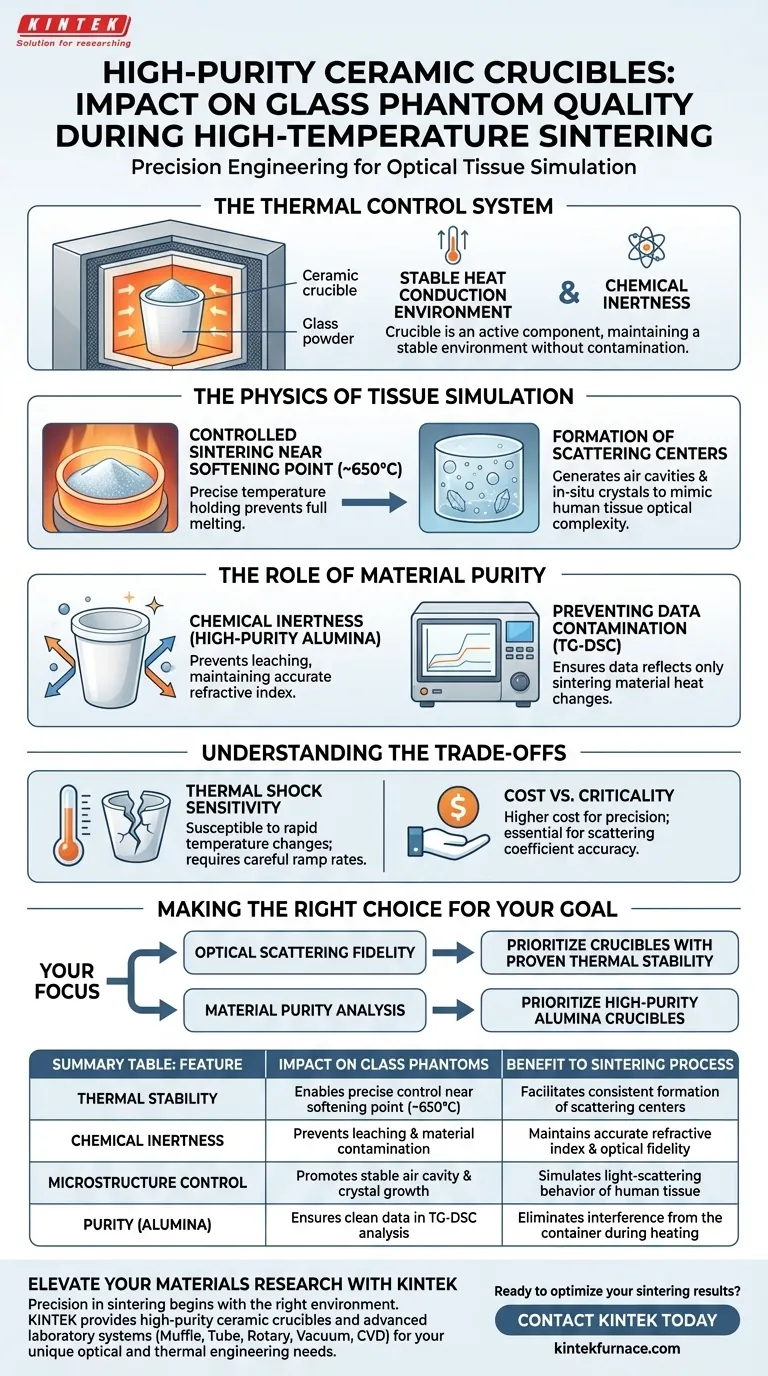

The selection of high-purity ceramic crucibles is a critical variable in manufacturing optical glass phantoms. These vessels provide the necessary thermal stability and chemical inertness required during the secondary sintering process. By ensuring a stable heat conduction environment, the crucible allows glass powder to be processed precisely near its softening point, facilitating the creation of the internal microstructures needed to simulate human tissue.

The crucible is not merely a container; it is an active component of the thermal control system. Its primary function is to maintain a stable environment that fosters the growth of specific scattering centers—air cavities and crystals—without introducing chemical contaminants that would skew the phantom's optical properties.

The Physics of Tissue Simulation

To understand the value of the crucible, you must understand the goal of the process: creating a material that mimics the light-scattering behavior of biological tissue.

Controlled Sintering Near the Softening Point

The manufacturing process often involves a secondary sintering phase at temperatures around 650°C.

At this specific thermal range, the glass powder is brought close to its softening point. High-purity ceramic crucibles provide the thermal stability requisite to hold this temperature precisely, preventing the glass from fully melting into a homogeneous block or failing to bond.

Formation of Scattering Centers

The ultimate goal of this controlled heating is the formation of scattering centers.

Because the crucible facilitates a stable heat conduction environment, the glass powder generates small air-filled cavities and in-situ crystals. These microstructures act as the physical mechanism that scatters light, simulating the optical complexity of human tissue.

The Role of Material Purity

Beyond thermal control, the chemical composition of the crucible dictates the integrity of the final product.

Chemical Inertness

High-purity crucibles, particularly those made of alumina, are prized for their chemical stability.

During sintering, molten or semi-molten glass is highly reactive. A high-purity crucible ensures that the container does not react with the mineral samples, preventing foreign elements from leaching into the glass and altering its refractive index or density.

Preventing Data Contamination

In analytical contexts like Thermogravimetric-Differential Scanning Calorimetry (TG-DSC), this inertness is vital.

It ensures that any thermal data collected reflects only the heat changes of the sintering material itself. This guarantees that the resulting phantom properties are purely a result of the glass formulation and the sintering schedule, free from interference or contamination from the container.

Understanding the Trade-offs

While high-purity ceramic crucibles are superior for precision applications, they require specific handling protocols.

Thermal Shock Sensitivity

Ceramics are generally susceptible to rapid temperature changes.

While they possess excellent heat resistance—often withstanding temperatures exceeding 1450°C—rapid heating or cooling can cause fracturing. The sintering ramp rates must be carefully calculated not just for the glass, but to preserve the integrity of the crucible.

Cost vs. Criticality

High-purity materials represent a higher consumable cost.

If the application does not require precise optical scattering—for example, a simple structural glass component—standard crucibles may suffice. However, for medical phantoms where scattering coefficient accuracy is paramount, the investment in high-purity ceramics is non-negotiable.

Making the Right Choice for Your Goal

The type of crucible you select should align with the specific fidelity requirements of your simulation.

- If your primary focus is Optical Scattering Fidelity: Prioritize crucibles with proven thermal stability to ensure the precise formation of air cavities and crystal structures.

- If your primary focus is Material Purity Analysis: Prioritize high-purity alumina crucibles to ensure absolute chemical inertness and prevent data interference.

By matching the crucible's thermal and chemical properties to your sintering goals, you turn a passive container into a tool for precision engineering.

Summary Table:

| Feature | Impact on Glass Phantoms | Benefit to Sintering Process |

|---|---|---|

| Thermal Stability | Enables precise control near the softening point (~650°C) | Facilitates consistent formation of scattering centers |

| Chemical Inertness | Prevents leaching and material contamination | Maintains accurate refractive index and optical fidelity |

| Microstructure Control | Promotes stable air cavity and crystal growth | Simulates the light-scattering behavior of human tissue |

| Purity (Alumina) | Ensures clean data in TG-DSC analysis | Eliminates interference from the container during heating |

Elevate Your Materials Research with KINTEK

Precision in sintering begins with the right environment. Backed by expert R&D and world-class manufacturing, KINTEK provides high-purity ceramic crucibles and advanced laboratory high-temperature systems—including Muffle, Tube, Rotary, Vacuum, and CVD systems—tailored for your unique optical and thermal engineering needs. Whether you are developing medical phantoms or high-tech glass, our customizable solutions ensure absolute purity and thermal control.

Ready to optimize your sintering results? Contact KINTEK today and let our experts design the perfect thermal solution for your laboratory.

Visual Guide

References

- Mingze Yang, Robert A. McLaughlin. Single and Bi‐Layer Glass‐Based Phantoms: Robust Materials for a Calibration Standard for Fluorescence Imaging Systems. DOI: 10.1002/adpr.202400209

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the alternative names for a Laboratory Furnace? Find the Right High-Temperature Tool for Your Lab

- What is the primary function of high-purity graphite crucibles? Ensure Superior Purity in Aluminum Alloy Melting

- How does the use of a high-purity quartz crucible affect silicate inclusions? Master Industrial Melt Simulation

- What should be evaluated when assessing supplier reliability for alumina ceramic furnace tubes? Ensure Consistent Performance and Support

- What is the primary function of a high-alumina powder crucible? Ensure Purity in Maraging Steel Pre-treatment

- Why is temperature resistance important for alumina ceramic furnace tubes? Ensure Safety and Performance in High-Temp Processes

- Why are high-purity quartz tubes and quartz boats preferred for plastic pyrolysis? Ensure Precise, Pure Results

- What type of motor does the circulating water multifunctional vacuum pump use? Discover Its Oil-Free Benefits