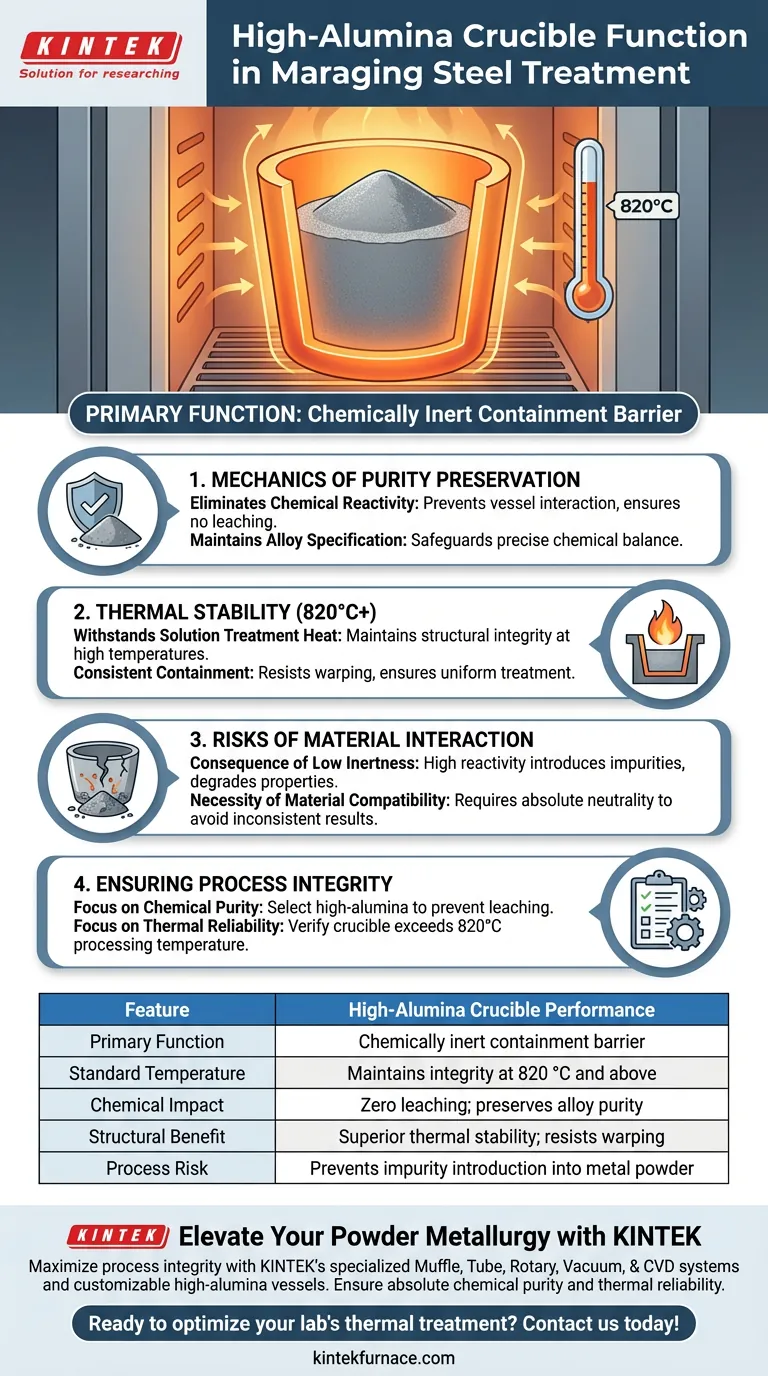

The primary function of a high-alumina powder crucible during the high-temperature solution pre-treatment of maraging steel powder is to act as a chemically inert containment barrier. Specifically, during treatments at temperatures such as 820 °C, the crucible prevents any chemical reaction between the vessel itself and the metal powder, thereby preserving the alloy's purity.

High-alumina crucibles serve as a critical isolation mechanism. Their superior thermal stability and chemical inertness ensure that high-temperature processing does not alter the delicate chemical composition of maraging steel through impurity introduction.

The Mechanics of Purity Preservation

Eliminating Chemical Reactivity

At elevated temperatures, metal powders become highly reactive. The high-alumina crucible leverages its superior chemical inertness to neutralize this risk.

By resisting interaction with the maraging steel, the crucible ensures that the container material does not leach into the powder. This is the only way to guarantee the alloy remains uncontaminated during the heating phase.

Maintaining Alloy Specification

Maraging steel relies on a precise chemical balance to achieve its material properties. Introducing external elements changes the alloy's behavior.

The high-alumina crucible acts as a safeguard, ensuring the chemical purity of the alloy components is maintained exactly as formulated.

Thermal Stability at Critical Temperatures

Withstanding Solution Treatment Heat

The solution pre-treatment process requires sustained exposure to high heat, specifically around 820 °C.

A standard vessel might degrade or soften at these temperatures. The high-alumina crucible maintains its structural integrity, providing a stable environment for the powder throughout the thermal cycle.

Consistent Containment

Beyond just surviving the heat, the crucible must remain physically stable to hold the powder securely.

Its thermal stability ensures that the vessel does not warp or fail, which would otherwise compromise the uniform treatment of the steel powder.

Understanding the Risks of Material Interaction

The Consequence of Low Inertness

If a crucible with lower alumina content or higher reactivity is used, the high surface area of the metal powder will likely facilitate a reaction.

This results in the introduction of impurities, which can degrade the mechanical properties of the final maraging steel product.

The Necessity of Material Compatibility

Not all high-temperature ceramics are suitable for all metals. The specific choice of high-alumina for maraging steel is driven by the need for absolute neutrality.

Using a substitute material introduces a variable that can lead to inconsistent results or batch rejection due to chemical alteration.

Ensuring Process Integrity

To maximize the quality of your maraging steel powder treatment, consider the following regarding your containment vessel:

- If your primary focus is Chemical Purity: Ensure you select a high-alumina crucible to prevent element leaching and maintain the strict composition of the alloy.

- If your primary focus is Thermal Reliability: Verify that the crucible's thermal rating exceeds the 820 °C processing temperature to prevent structural failure during treatment.

The success of high-temperature solution treatment relies not just on the heat applied, but on the inert nature of the vessel holding the material.

Summary Table:

| Feature | High-Alumina Crucible Performance |

|---|---|

| Primary Function | Chemically inert containment barrier |

| Standard Temperature | Maintains integrity at 820 °C and above |

| Chemical Impact | Zero leaching; preserves alloy purity |

| Structural Benefit | Superior thermal stability; resists warping |

| Process Risk | Prevents impurity introduction into metal powder |

Elevate Your Powder Metallurgy with KINTEK

Maximize the integrity of your high-temperature processes with KINTEK’s specialized containment solutions. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside customizable high-alumina vessels designed for the most demanding lab environments.

Whether you are processing maraging steel or developing advanced alloys, our equipment ensures absolute chemical purity and thermal reliability.

Ready to optimize your lab's thermal treatment? Contact us today to discuss your unique needs!

Visual Guide

References

- Innovative Powder Pre-Treatment Strategies for Enhancing Maraging Steel Performance. DOI: 10.3390/ma18020437

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the purpose of a water-cooling jacket in a methane cracking reactor? Prevent Blockages & Thermal Damage

- How are laboratory vacuum pumps utilized in 1T-TaS2 crystal preparation? Ensure Peak Sample Purity

- What is the function of graphite stirring rods in aluminum casting? Achieve Perfect Alloy Homogenization

- What function do graphite chill plates or chill rings perform? Master Single-Crystal Blade Directional Solidification

- What other industrial applications do graphite crucible furnaces have beyond metal melting? Unlock Advanced Material Processing

- Why is a laboratory-grade high-pressure reactor essential for TiO2 nanoparticles? Optimize Purity and Efficiency

- What is the function of Mass Flow Controllers (MFC) in the gas proportioning process for co-combustion experiments?

- What materials are commonly used for furnace tubes to withstand high heat? Choose the Best for Your Lab