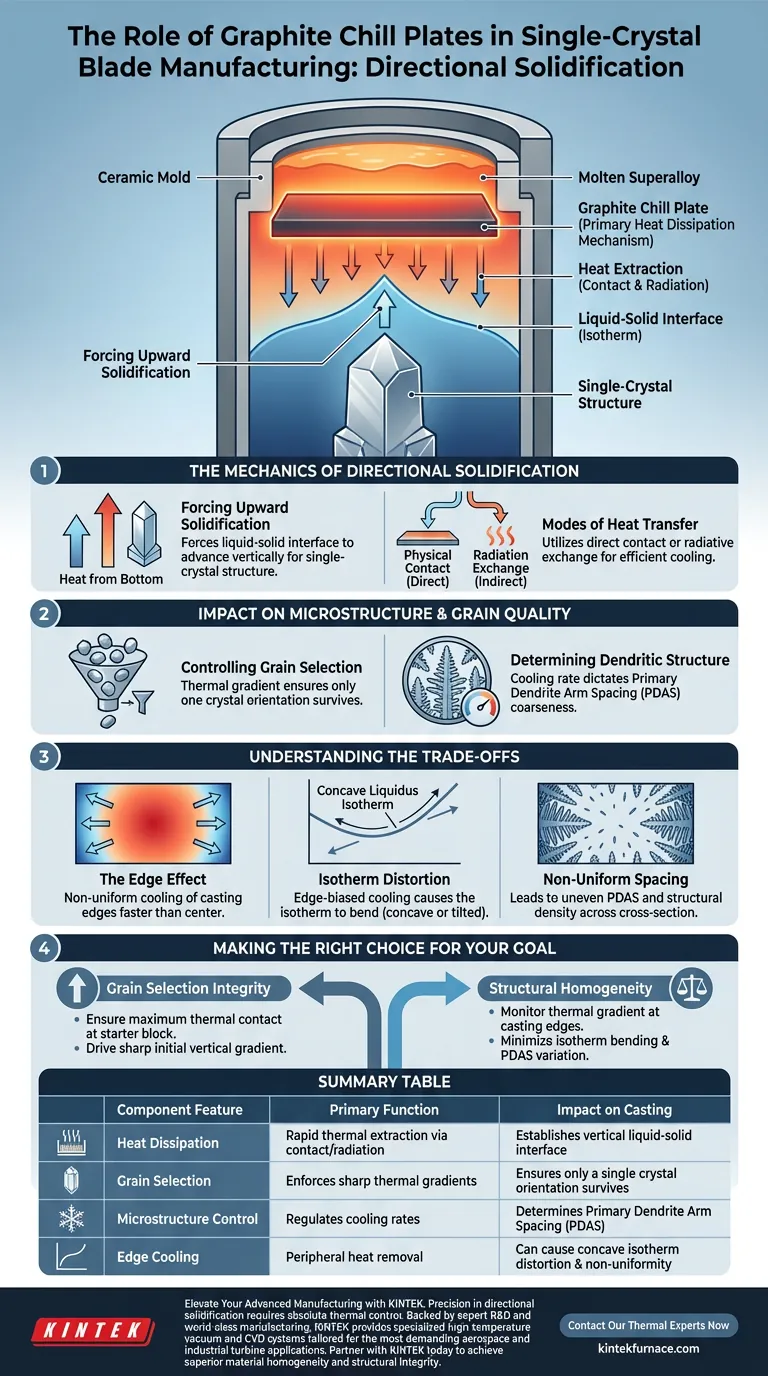

Graphite chill plates and rings act as the primary heat dissipation mechanism within directional solidification systems used for manufacturing single-crystal blades. By engaging in physical contact or radiative heat exchange with ceramic molds, these components rapidly extract heat from the bottom and sides of the casting, driving the liquid-solid interface upward to strictly control the solidification front.

The fundamental role of these components is to enforce a vertical thermal gradient that dictates crystal growth. While they are critical for initial grain selection, their localized cooling effects also introduce complex thermal variations across the blade’s cross-section.

The Mechanics of Directional Solidification

Forcing Upward Solidification

The primary function of graphite chill plates is to create a controlled direction of solidification.

By removing heat rapidly from the bottom of the mold, they force the liquid-solid interface to advance vertically. This directional movement is the foundational requirement for creating single-crystal structures.

Modes of Heat Transfer

These graphite components utilize two specific methods to extract thermal energy.

They operate through either direct physical contact with the mold or through radiation heat exchange. This dual approach ensures efficient cooling at the critical initial stages of the casting process.

Impact on Microstructure and Grain Quality

Controlling Grain Selection

The cooling provided by chill plates directly influences the success of the grain selection process.

The thermal gradient they establish is vital for the proper function of the starter block and grain selector stages. This ensures that only a single, desirable crystal orientation survives to form the blade body.

Determining Dendritic Structure

Beyond the initial selection, the rate of heat extraction dictates the internal structure of the material.

The intensity of the cooling influences the coarseness of the dendritic structure. Specifically, it controls the primary dendrite arm spacing (PDAS), a critical metric for the mechanical properties of the final blade.

Understanding the Trade-offs

The Edge Effect

While chill rings are necessary for rapid cooling, they introduce non-uniformity by cooling the edges of the casting faster than the center.

This enhanced heat exchange at the periphery creates a significant thermal difference between the outer skin and the core of the blade.

Isotherm Distortion

This edge-biased cooling causes the liquidus isotherm—the line separating liquid from solid—to bend.

Instead of a perfectly flat horizontal line, the thermal profile often becomes concave or tilted. This distortion complicates the growth front and can lead to structural defects if not managed.

Non-Uniform Spacing

The variation in cooling rates across the cross-section leads to physical inconsistencies in the material.

Because the heat removal is non-uniform, the primary dendrite arm spacing (PDAS) becomes uneven. You will often observe different structural densities at the edges compared to the center of the casting.

Making the Right Choice for Your Goal

To optimize your directional solidification process, you must balance rapid heat extraction with thermal homogeneity.

- If your primary focus is Grain Selection Integrity: Ensure maximum thermal contact at the starter block to drive a sharp initial vertical gradient.

- If your primary focus is Structural Homogeneity: Monitor the thermal gradient at the casting edges to minimize the bending of the liquidus isotherm and reduce PDAS variation.

Mastering the use of graphite chills is about managing the delicate balance between directional force and cross-sectional uniformity.

Summary Table:

| Component Feature | Primary Function | Impact on Casting |

|---|---|---|

| Heat Dissipation | Rapid thermal extraction via contact/radiation | Establishes the vertical liquid-solid interface |

| Grain Selection | Enforces sharp thermal gradients | Ensures only a single crystal orientation survives |

| Microstructure Control | Regulates cooling rates | Determines Primary Dendrite Arm Spacing (PDAS) |

| Edge Cooling | Peripheral heat removal | Can cause concave isotherm distortion and non-uniformity |

Elevate Your Advanced Manufacturing with KINTEK

Precision in directional solidification requires absolute thermal control. Backed by expert R&D and world-class manufacturing, KINTEK provides specialized high-temperature vacuum and CVD systems tailored for the most demanding aerospace and industrial turbine applications.

Whether you are optimizing grain selection or seeking to eliminate structural defects in single-crystal blades, our customizable lab and industrial furnaces deliver the performance you need. Partner with KINTEK today to achieve superior material homogeneity and structural integrity.

Contact Our Thermal Experts Now

Visual Guide

References

- Effect of Temperature Profile Curvature on the Formation of Atypical Inhomogeneity of Dendritic Microstructure Across the Width of a Single Crystal Blade. DOI: 10.1007/s11661-025-07909-y

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Stainless Steel KF ISO Vacuum Flange Blind Plate for High Vacuum Systems

People Also Ask

- What is the specific purpose of using a graphite crucible equipped with a plug during the melting process of Mg3Sb2?

- What are the requirements for an alumina boat for Mn2AlB2 sintering? Ensure High-Purity Material Processing

- Why are high-purity crucibles and sealed reaction environments necessary for NaRu2O4 growth? Ensure Crystal Integrity

- What are the benefits of a vacuum chamber? Achieve Unmatched Process Control and Purity

- What is the significance of using ceramic balls of varying diameters? Optimize Reactor Flow and Filtration

- What is the function of a rotary vane vacuum pump in a thermal vacuum mercury removal system? Enhance Evaporative Efficiency

- What are the specific functions of a magnetic stirrer and a condenser reflux apparatus in the synthesis of KCC-1? Expert Insights

- What are the primary functions of high-purity graphite molds in the SPS of TiB2 ceramics? Enhance Sintering Precision