At its core, a vacuum chamber is an instrument of control. Its primary benefit is the ability to create a precisely managed environment by removing air and other gases, which prevents unwanted chemical reactions, reduces contamination, and allows for processes that are impossible under normal atmospheric pressure. This control is leveraged across industries to test products, enhance material properties, and enable advanced manufacturing techniques.

The true value of a vacuum chamber isn't simply removing air. It is about gaining absolute authority over a physical space, eliminating the unpredictable variables of our atmosphere to achieve purity, stability, and performance that would otherwise be unattainable.

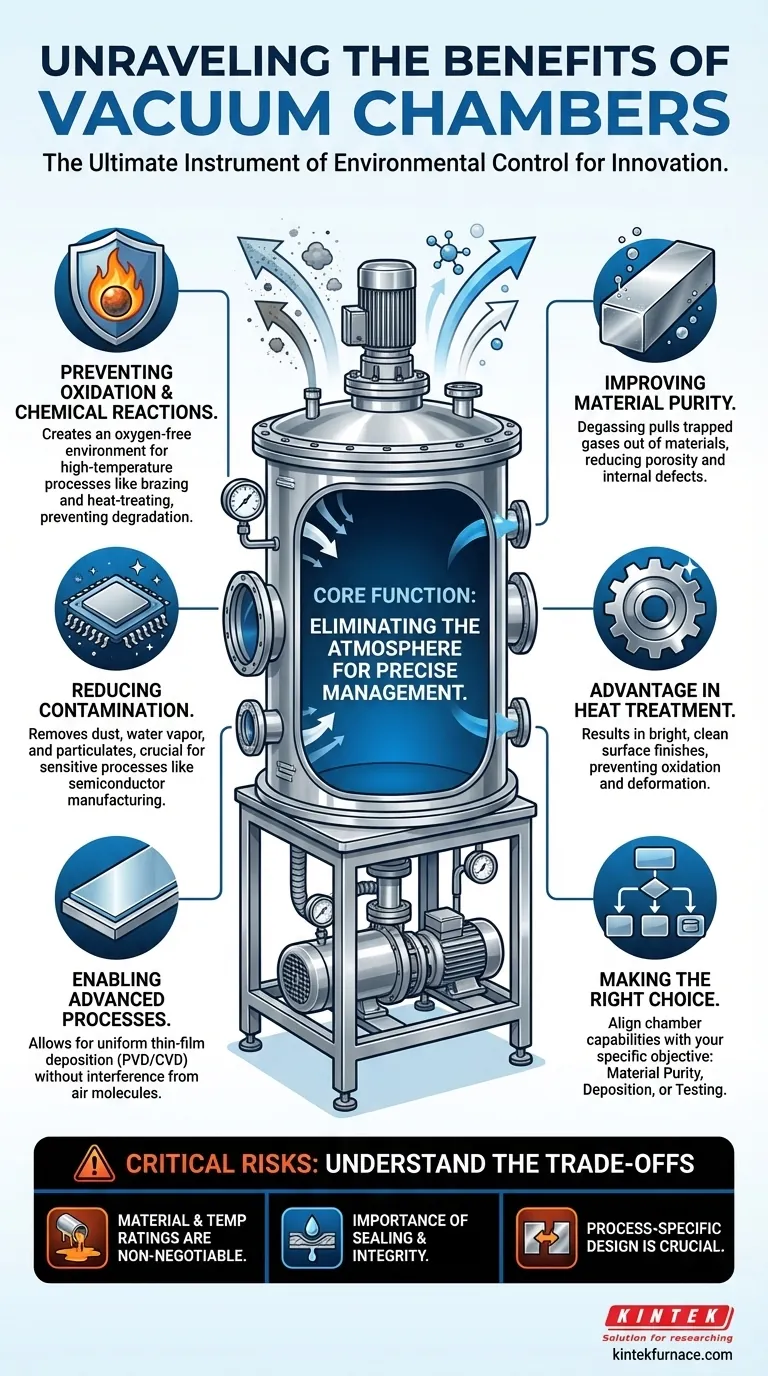

The Principle of Control: Eliminating the Atmosphere

The fundamental purpose of a vacuum chamber is to isolate a process from the uncontrolled and reactive environment of the air we breathe.

How a Vacuum Chamber Works

The operation is conceptually simple. First, a chamber is built from durable materials like stainless steel that can withstand immense external pressure. All entry points are sealed. Then, one or more vacuum pumps actively remove air and other gaseous molecules, lowering the internal pressure. Gauges monitor this pressure, allowing an operator to perform an experiment or manufacturing process once the desired vacuum level is reached.

Preventing Unwanted Chemical Reactions

The most common unwanted reaction is oxidation. When heated, many materials react aggressively with the oxygen in the air, leading to degradation, scaling, and compromised structural integrity. By removing the oxygen, a vacuum chamber allows for high-temperature processes like brazing and heat-treating without this damage.

Reducing Particle Contamination

Our atmosphere is filled with dust, water vapor, and other particulates. In sensitive processes like semiconductor manufacturing or thin-film deposition, these particles can cause catastrophic defects. A vacuum environment is inherently an ultra-clean environment, ensuring processes are performed with maximum purity.

Enhancing Material Properties and Processes

By controlling the environment, vacuum technology directly improves the quality and performance of materials and the efficiency of manufacturing processes.

Improving Material Purity and Structure

Creating a vacuum can pull trapped gases, including hydrogen and oxygen, out of a molten metal or solid material. This degassing process reduces internal defects and porosity, leading to stronger, more reliable components with enhanced properties like electrical conductivity.

The Advantage in Heat Treatment

Vacuum hardening is a prime example of a process benefit. By heating and cooling a workpiece in a vacuum, you prevent surface oxidation and decarburization. This results in a bright, clean surface finish that often requires no secondary cleaning and prevents the workpiece deformation common in atmospheric furnaces.

Enabling Advanced Deposition

Processes like physical vapor deposition (PVD) or chemical vapor deposition (CVD) are used to apply extremely thin coatings to tools, electronics, and optics. These processes require a vacuum to allow vaporized coating material to travel from its source to the target without colliding with air molecules, ensuring a uniform and dense coating.

Understanding the Trade-offs and Critical Risks

While powerful, a vacuum chamber is a specialized tool with significant operational risks. Misunderstanding its limitations can lead to process failure or catastrophic accidents.

Material and Temperature Ratings are Non-Negotiable

A chamber's material, typically stainless steel, and its construction dictate its maximum safe operating temperature and pressure differential. Heating a chamber not rated for high temperatures, for example, can cause the steel to warp, break its seals, or even release trapped gases from the metal itself (a phenomenon called outgassing), ruining the vacuum.

The Importance of Sealing and Integrity

The entire system is only as good as its weakest point. A tiny leak in a seal, gauge, or feedthrough will prevent the chamber from reaching the desired vacuum level. In processes involving reactive gases, a leak can introduce oxygen or moisture, creating a hazardous or explosive mixture.

Process-Specific Design is Crucial

A chamber designed for one process, like glow discharge, is not automatically suitable for another, like high-temperature annealing. The pumps, seals, power supplies, and cooling systems are all selected for a specific range of pressures and temperatures. Using a chamber outside its designed purpose without expert modification is a significant safety risk.

Making the Right Choice for Your Goal

To leverage these benefits effectively, you must align the chamber's capabilities with your specific objective.

- If your primary focus is material purity and heat treatment: Seek a chamber with documented high-temperature ratings and construction materials that minimize outgassing under thermal load.

- If your primary focus is thin-film deposition or coating: Prioritize a high-vacuum system with instrumentation and pumps designed for low pressures and compatibility with deposition sources.

- If your primary focus is environmental testing: Ensure the chamber is designed with the necessary ports and controllers to safely introduce and manage specific temperatures, pressures, or gases.

- If you are adapting an existing chamber for a new process: You must have every component—the chamber body, seals, gauges, and power systems—expertly verified to ensure it is safe and suitable for the new operating conditions.

Understanding a vacuum chamber as a tool for precise environmental control is the first step toward unlocking its full potential for innovation and quality.

Summary Table:

| Key Benefit | Core Function | Primary Application |

|---|---|---|

| Prevents Contamination | Removes dust, moisture, and particulates | Semiconductor manufacturing, thin-film deposition |

| Eliminates Oxidation | Creates an oxygen-free environment for high-temperature processes | Brazing, heat treatment, vacuum hardening |

| Enables Advanced Processes | Allows vaporized materials to travel without interference | PVD/CVD coating, degassing, material purification |

| Improves Material Integrity | Removes trapped gases to reduce porosity and defects | Metalworking, component manufacturing, R&D |

Ready to harness the power of a controlled environment for your lab?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced vacuum furnace solutions tailored to your unique needs. Whether you require a standard Muffle or Tube Furnace, or a highly customized Vacuum & Atmosphere system for processes like PVD/CVD, our expertise ensures you get the precise control and purity your experiments demand.

Contact us today to discuss how our vacuum solutions can enhance your material properties and manufacturing processes!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What are the advantages of a vacuum hot pressing sintering furnace for rare earth copper composites? Density & Purity

- Why must sintering equipment maintain a high vacuum for high-entropy carbides? Ensure Phase Purity and Peak Density

- Why is a vacuum hot press sintering furnace required for nanocrystalline ceramics? Preserve Structure with Pressure

- How does pressure application in a vacuum hot press furnace facilitate sintering of copper composites? Optimize Density

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures