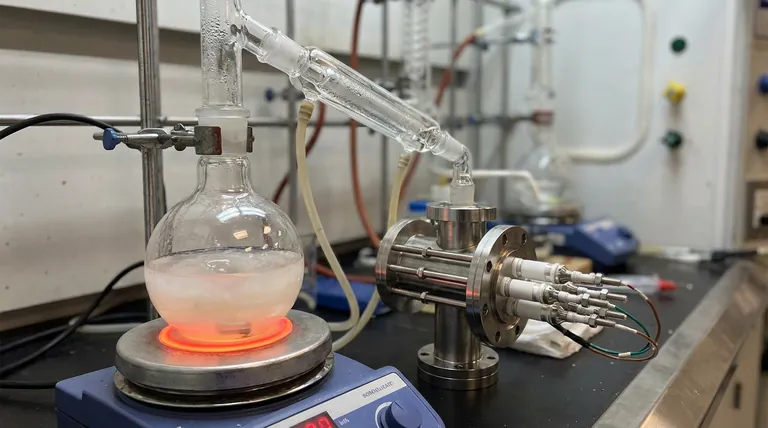

In the synthesis of KCC-1 dendritic silica nanostructures, the magnetic stirrer serves to create a stable microemulsion through uniform dispersion of reactants, while the condenser reflux apparatus maintains critical chemical stoichiometry by preventing solvent evaporation at high temperatures. These two instruments work in tandem to establish the precise physical and chemical environment required for the unique fibrous morphology of KCC-1.

The successful formation of KCC-1 relies on the synergy between rigorous physical mixing to establish a template-guided microemulsion and a closed reflux system that preserves the exact chemical balance required for 3D dendritic growth.

The Role of the Magnetic Stirrer

The magnetic stirrer is the primary driver of physical homogeneity within the reaction vessel. Its function goes beyond simple agitation; it is essential for the formation of the "soft template" system.

Achieving Uniform Dispersion

The synthesis involves a complex mixture of CTAB (the template), urea, TEOS (the silica source), and various solvents. The magnetic stirrer ensures these distinct components are thoroughly mixed rather than settling into separate phases.

Establishing the Microemulsion

By maintaining constant agitation, the stirrer facilitates the formation of a stable microemulsion system. This stability is a prerequisite for the template-directed growth mechanism that defines KCC-1 synthesis.

The Role of the Condenser Reflux Apparatus

While the stirrer handles the physical mixture, the condenser reflux apparatus manages the thermodynamic and chemical environment. It allows the reaction to proceed at elevated temperatures without compromising the mixture's composition.

Maintaining Thermal Stability

The apparatus operates in a constant temperature environment, specifically maintained at 80 °C. This thermal energy is necessary to drive the chemical reaction kinetics required for silica condensation.

Preventing Solvent Evaporation

At 80 °C, volatile solvents would typically evaporate rapidly, leaving the reaction vessel. The condenser captures these vapors, cools them, and returns them to the liquid phase, keeping the system "closed."

Preserving Chemical Stoichiometry

By preventing the loss of solvent, the apparatus ensures the concentration of reactants remains constant throughout the synthesis. This stability maintains the specific chemical stoichiometry required for the reaction to proceed predictably.

The Impact on Nanostructure Morphology

The ultimate goal of using these specific tools is to control the physical shape of the final silica product.

Guiding Dendritic Growth

The combination of a stable microemulsion and fixed stoichiometry ensures the silica grows into nanospheres with a specific three-dimensional dendritic structure.

Facilitating Soft Template Assembly

The precise environment allows the silica precursor to polymerize around the CTAB template correctly. This results in the characteristic fibrous surface area that makes KCC-1 unique compared to solid silica spheres.

Common Pitfalls and Sensitivities

Understanding the sensitivity of this synthesis helps in troubleshooting failed batches or irregular structures.

Inadequate Agitation

If the magnetic stirrer fails to maintain a uniform speed, the microemulsion may destabilize. This lack of homogeneity can prevent the formation of the dendritic network, leading to irregular particle shapes.

Loss of Stoichiometry

If the condenser system leaks or fails to cool vapors efficiently, solvent loss will alter the concentration of reactants. A shift in stoichiometry disrupts the delicate balance needed for the template mechanism, often resulting in non-dendritic or collapsed structures.

Making the Right Choice for Your Synthesis

To ensure high-quality KCC-1 production, focus on the precision of your equipment setup.

- If your primary focus is structural uniformity: Ensure your magnetic stirrer is set to a speed that guarantees a vortex-free but thoroughly dispersed microemulsion.

- If your primary focus is reproducibility: Verify the seal and cooling efficiency of your reflux condenser to guarantee zero solvent loss during the 80 °C reaction phase.

Precise control over mixing dynamics and solvent retention is the non-negotiable key to unlocking the high surface area of dendritic silica.

Summary Table:

| Equipment | Primary Function | Impact on KCC-1 Morphology |

|---|---|---|

| Magnetic Stirrer | Creates stable microemulsion via uniform dispersion | Ensures formation of 3D dendritic structure |

| Condenser Reflux | Prevents solvent evaporation at 80 °C | Maintains stoichiometry for fibrous surface growth |

| Synergy | Physical and chemical stability | Produces high-surface-area nanospheres |

Elevate Your Nanomaterial Synthesis with KINTEK

Precision is non-negotiable when synthesizing complex nanostructures like KCC-1. At KINTEK, we understand that high-quality outcomes depend on rigorous thermal and physical control.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of lab equipment including Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as precision stirring and reflux solutions. Our systems are fully customizable to meet your unique research requirements, ensuring stable microemulsions and perfect stoichiometry every time.

Ready to optimize your lab's performance? Contact us today to discuss how our high-temperature furnaces and lab solutions can enhance your material science breakthroughs.

References

- Farzaneh Edrisi, Nasrin Shadjou. Preparation of an innovative series of respiratory nano-filters using polystyrene fibrous films containing KCC-1 dendrimer and ZnO nanostructures for environmental assessment of SO<sub>2</sub>, NO<sub>2</sub> and CO<sub>2</sub>. DOI: 10.1039/d4ra00176a

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- Why is a molybdenum crucible considered an ideal choice for quartz melting? High-Purity Solutions at 2000°C

- Why are laboratory heating and stirring devices necessary for Pechini and sol-gel synthesis? Ensure Precise Homogeneity

- What are the technical considerations for selecting a graphite crucible? Expert Insights for Molten Salt Electrolysis

- Why is a semi-closed alumina crucible required for g-C3N4? Maximize Your Synthesis Yield and Quality

- How do alumina ceramic furnace tubes compare to other materials like quartz or silicon carbide? Choose the Best for Your High-Temp Needs

- Why are laboratory vacuum pumps and pressure gauges essential for aluminum foams? Ensure High-Quality Sintering Results

- What are the advantages of using high-purity alumina crucibles? Achieve Precise Cast Iron Phase Equilibrium Data

- What role does a mass flow controller (MFC) play in plasma-based aluminum reduction? Precision Control for High Yields