In choosing a furnace tube, alumina ceramic stands out for its exceptional combination of high-temperature stability (up to 1700°C) and broad chemical resistance, making it a robust workhorse for many applications. It directly competes with quartz, which is valued for its optical transparency and extreme purity, and silicon carbide, which offers superior thermal conductivity for rapid temperature cycling.

The core decision is not about finding a single "best" material, but about matching a material's specific strengths to your operational priorities. Alumina is the high-performance generalist, but specialized needs like visual monitoring, absolute purity, or rapid heating will steer you toward quartz or silicon carbide.

Deconstructing the Key Properties

To make an informed decision, you must first understand the fundamental properties that differentiate these materials. Each one represents a trade-off in performance, durability, and cost.

Thermal Resistance

A tube's primary function is to contain a process at high temperatures. Its maximum operating temperature is the most critical starting point for selection.

Alumina is an excellent high-temperature material, with high-purity grades capable of stable operation up to 1700°C. This makes it suitable for a vast range of metallurgical and materials science applications.

Chemical Inertness and Purity

A furnace tube must not react with or contaminate the sample or process atmosphere inside it. This is a function of both chemical resistance and material purity.

Alumina offers excellent resistance to most acids, alkalis, and solvents, making it a reliable choice for chemically aggressive environments.

Quartz, however, offers the highest purity, often exceeding 99.99%. This is critical in applications like semiconductor manufacturing, where even trace contaminants can ruin a product.

Mechanical Strength and Hardness

The tube must withstand mechanical stresses, from installation to operational loads and surface abrasion.

Alumina is an exceptionally hard material with a Rockwell hardness (HRA) of 80-90, second only to diamond. This translates to outstanding wear and abrasion resistance. Its high compressive and flexural strength ensures it maintains structural integrity under load.

Thermal Conductivity

This property dictates how quickly heat moves through the tube wall. It has a major impact on process speed and temperature uniformity.

Silicon carbide (SiC) is the clear leader here, with superior thermal conductivity. This allows for rapid heating and cooling cycles and promotes a more uniform temperature zone inside the furnace.

In contrast, alumina and quartz are thermal insulators. While this helps maintain high temperatures, it means they heat up and cool down more slowly.

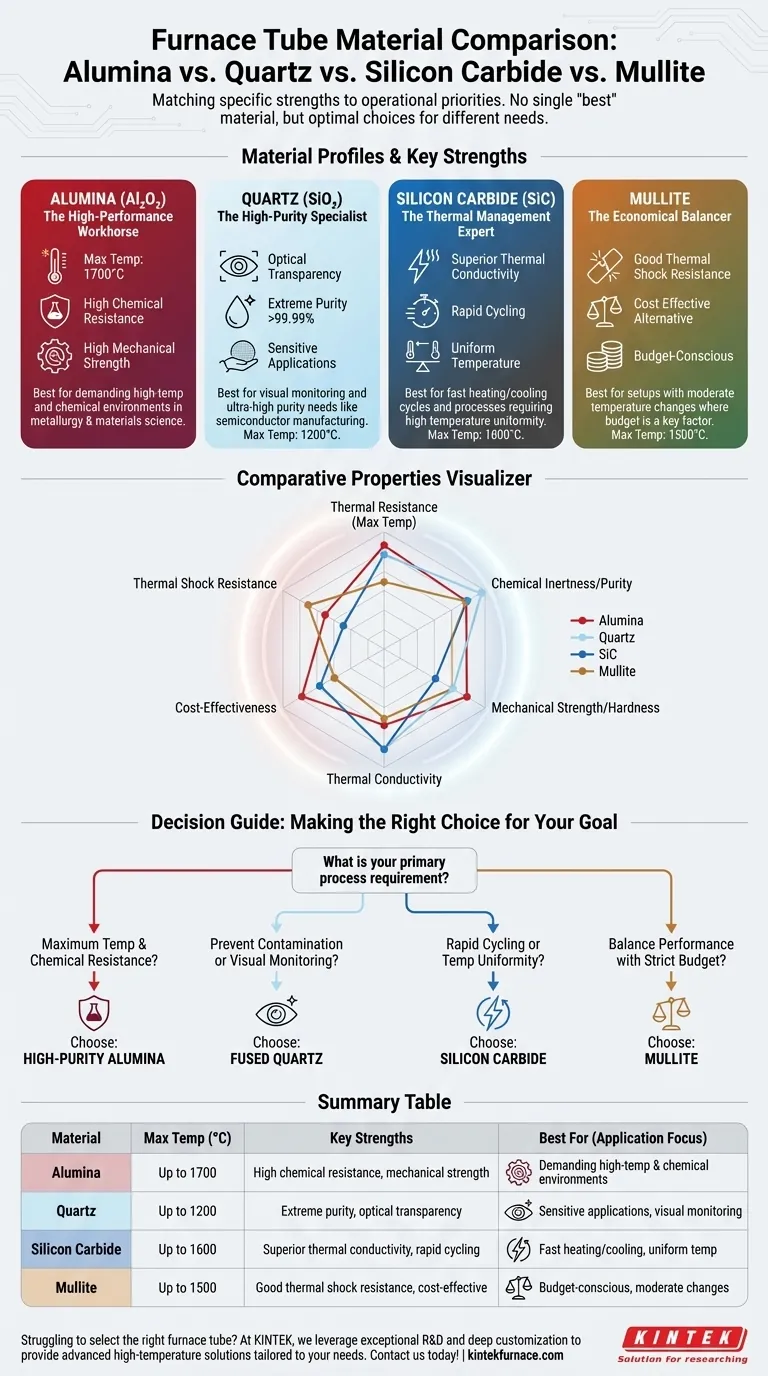

A Comparative Analysis of Materials

With these properties in mind, we can compare how each material fits into different application profiles.

Alumina (Al₂O₃): The High-Performance Workhorse

Alumina is often the default choice for demanding applications that do not require visual monitoring. Its blend of extreme temperature resistance, chemical inertness, and high mechanical strength provides a durable and reliable solution for general-purpose use in metallurgy, chemical processing, and heat treatment.

Quartz (SiO₂): The High-Purity Specialist

The primary advantages of quartz are its optical transparency and extreme purity. If you need to visually observe a process as it happens, quartz is your only option. Its ultra-low level of impurities also makes it essential for sensitive applications where any contamination is unacceptable.

Silicon Carbide (SiC): The Thermal Management Expert

Choose silicon carbide when thermal performance is paramount. Its ability to transfer heat quickly makes it ideal for furnaces with rapid cycling times or for processes that demand the highest degree of temperature uniformity across the sample.

Mullite: The Economical Balancer

Mullite is a ceramic material that serves as a cost-effective alternative to high-purity alumina. It provides a good balance of properties, with a particular strength in thermal shock resistance, making it less prone to cracking during moderate temperature changes.

Understanding the Trade-offs

No material is perfect. Acknowledging their inherent limitations is crucial for avoiding costly failures.

Cost vs. Purity and Performance

Higher performance and purity come at a price. Ultra-high purity quartz and specialized silicon carbide tubes are significantly more expensive than standard alumina. Mullite represents the most budget-conscious option.

Thermal Shock Sensitivity

While alumina excels at sustained high temperatures, it can be brittle and susceptible to cracking if heated or cooled too quickly. Materials like mullite or silicon carbide often offer better resistance to thermal shock.

Opacity and Process Visibility

The most obvious drawback of alumina, silicon carbide, and mullite is that they are opaque. This completely prevents direct visual inspection of the process, a non-starter for certain types of research and development.

Making the Right Choice for Your Goal

Your final decision should be guided by your single most important process requirement.

- If your primary focus is maximum temperature and chemical resistance: High-purity alumina is your most reliable and robust choice for demanding environments.

- If your primary focus is preventing sample contamination or visual process monitoring: Fused quartz is the unambiguous solution due to its extreme purity and transparency.

- If your primary focus is rapid heating/cooling cycles or temperature uniformity: Silicon carbide's superior thermal conductivity makes it the ideal material.

- If your primary focus is balancing performance with a strict budget: Mullite provides excellent thermal shock resistance and good overall properties at a more accessible price point.

By aligning the material's core strengths with your specific process requirements, you ensure operational reliability and optimal results.

Summary Table:

| Material | Max Temperature (°C) | Key Strengths | Best For |

|---|---|---|---|

| Alumina | Up to 1700 | High chemical resistance, mechanical strength | Demanding high-temp and chemical environments |

| Quartz | Up to 1200 | Extreme purity, optical transparency | Sensitive applications requiring visual monitoring |

| Silicon Carbide | Up to 1600 | Superior thermal conductivity, rapid cycling | Fast heating/cooling and uniform temperature |

| Mullite | Up to 1500 | Good thermal shock resistance, cost-effective | Budget-conscious setups with moderate changes |

Struggling to select the right furnace tube for your lab's unique needs? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your experimental requirements, whether you prioritize temperature stability, purity, rapid cycling, or cost-efficiency. Let us help you enhance operational reliability and achieve optimal results—contact us today for a tailored consultation!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency