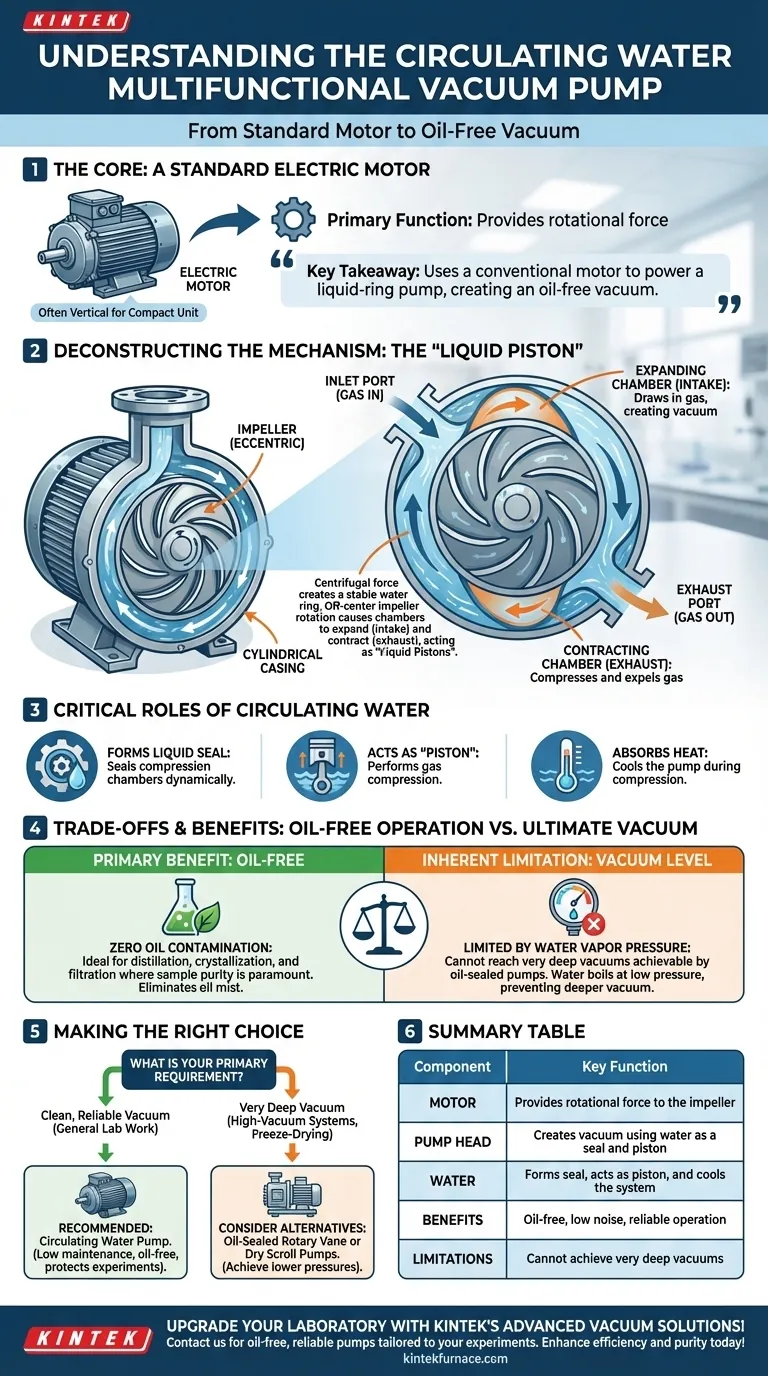

At its core, the circulating water multifunctional vacuum pump uses a standard electric motor, which is often installed vertically to create a compact, self-contained unit. The motor's primary function is to drive a specialized pump mechanism that uses water, not oil, to generate a vacuum.

The specific motor is less important than the principle it enables. The key takeaway is that this device uses a conventional motor to power a liquid-ring pump, which creates an oil-free vacuum ideal for clean laboratory and small-scale production environments.

Deconstructing the Pump's Core Mechanism

To understand this pump, you must look past the motor and focus on the ingenious method it uses to create negative pressure. The motor is the power source, but the pump head is where the work is done.

The Drive Motor: A Supporting Role

The motor itself is typically a standard, reliable electric motor. The "vertical motor" designation you may encounter refers to its orientation, a design choice that allows for a smaller footprint, making the unit more convenient and flexible for placement in a crowded lab. The motor's sole job is to provide rotational force to the impeller.

The "Liquid Piston": How Vacuum Is Created

This device is a type of liquid-ring vacuum pump. An impeller with curved blades spins eccentrically (off-center) inside a cylindrical pump casing.

As the motor spins the impeller, centrifugal force throws the circulating water against the outer wall of the casing, forming a stable ring of liquid. Because the impeller is off-center, the space between the impeller blades and the water ring continuously changes.

This action creates a series of sealed chambers that expand and contract with each rotation, acting like a set of radially moving "liquid pistons." As a chamber expands, it draws in gas from the inlet port (creating a vacuum). As it contracts, it compresses the gas and expels it through the exhaust port.

The Role of Circulating Water

The water is the working fluid, not simply a coolant. It serves three critical functions:

- It forms the dynamic, liquid seal for the compression chambers.

- It acts as the "piston" that performs the gas compression.

- It absorbs the heat of compression, keeping the pump cool.

Understanding the Trade-offs and Benefits

The liquid-ring design is chosen for its specific advantages in certain applications, but it's essential to understand its inherent limitations.

The Primary Benefit: Oil-Free Operation

Because water is the only sealant and lubricant in the vacuum chamber, there is zero risk of oil contamination. This makes the pump perfect for processes like distillation, crystallization, and filtration, where sample purity is paramount. It eliminates the oil mist associated with traditional oil-sealed pumps.

An Inherent Limitation: Ultimate Vacuum Level

The ultimate vacuum this pump can achieve is limited by the vapor pressure of the water being used. As the pressure in the system drops, the water in the ring will begin to boil, preventing a deeper vacuum from forming. This means it cannot reach the very low pressures achievable by an oil-sealed rotary vane or turbomolecular pump.

Other Considerations: Noise and Convenience

These pumps are generally characterized by low noise and stable operation. The circulating water dampens mechanical sounds. However, they do require a water source, and the exhaust gas will be saturated with water vapor, which may need to be considered depending on your process.

Making the Right Choice for Your Application

Selecting the correct vacuum pump depends entirely on the requirements of your specific task.

- If your primary focus is a clean, reliable vacuum for general chemistry or biology lab work: This pump is an excellent, low-maintenance choice that protects your experiments from oil contamination.

- If your primary focus is achieving a very deep vacuum for high-vacuum systems or freeze-drying: You should look to other technologies, such as an oil-sealed rotary vane pump or a completely dry scroll pump.

Ultimately, understanding the pump's water-based mechanism empowers you to choose the right tool for your specific scientific goal.

Summary Table:

| Component | Description | Key Function |

|---|---|---|

| Motor | Standard electric motor, often vertical | Provides rotational force to the impeller |

| Pump Head | Liquid-ring vacuum pump mechanism | Creates vacuum using water as a seal and piston |

| Water | Circulating working fluid | Forms seal, acts as piston, and cools the system |

| Benefits | Oil-free operation, low noise, reliable | Prevents contamination, suitable for clean environments |

| Limitations | Limited by water vapor pressure | Cannot achieve very deep vacuums like oil-sealed pumps |

Upgrade your laboratory with KINTEK's advanced vacuum solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces and more. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization to meet your unique needs. For oil-free, reliable vacuum pumps tailored to your experiments, contact us today to discuss how we can enhance your lab's efficiency and purity!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What technical considerations justify the use of high-purity alumina crucibles for microwave-assisted metal reduction?

- Why are high-purity crucibles and sealed reaction environments necessary for NaRu2O4 growth? Ensure Crystal Integrity

- What are the main reasons for the alumina furnace tube being prone to breaking? Prevent Costly Failures with Expert Tips

- What are the advantages of using an infrared thermograph over traditional thermocouples in Plasma Flash Sintering (PFS)?

- What maintenance is required for a water circulating vacuum pump? Ensure Peak Performance and Longevity

- Why are high-purity alumina crucibles required for the cook-off method? Ensure Safety & Catalyst Purity

- What is the technical value of using a narrowband infrared pyrometer? Expert Precision for High-Temp Measurement

- What are the main components of a Laboratory Furnace? Essential Parts for Precise High-Temperature Processing