At its core, a laboratory furnace's customization extends far beyond simple size and temperature adjustments. You can specify nearly every aspect of its operation, including the internal atmosphere, the materials it's built from, the precision of its control system, and a range of ancillary equipment to match your exact scientific or industrial process.

The goal of furnace customization is not just to reach a target temperature, but to gain precise, repeatable control over the entire thermal environment. This control is what ensures the integrity of your process and the quality of your results.

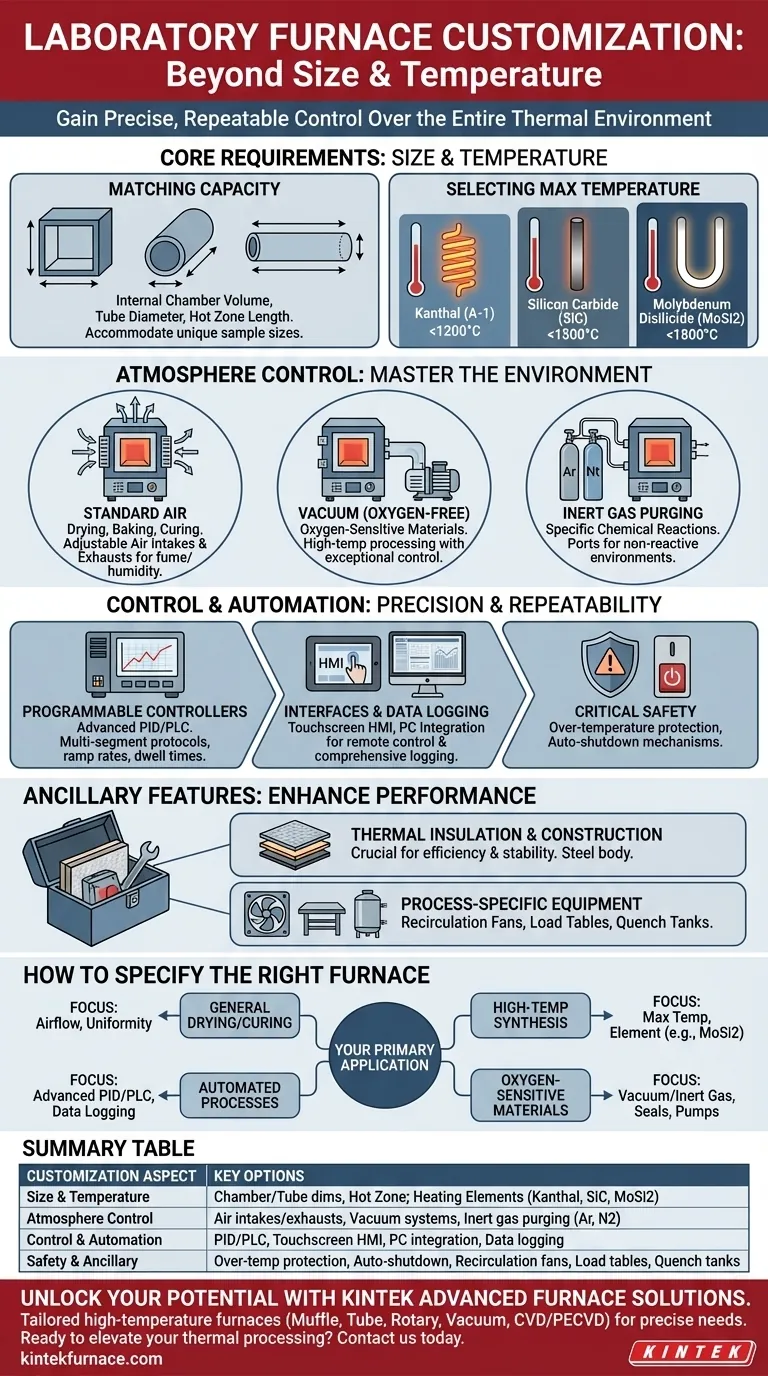

Defining Your Core Requirements: Size and Temperature

Before considering advanced features, you must define the fundamental physical and thermal parameters your work demands. These choices form the foundation of your furnace's design.

Matching Capacity to Your Workflow

The physical dimensions of the furnace must accommodate your samples. This includes the internal chamber volume or, for tube furnaces, the tube diameter and the length of the hot zone.

Standard tube diameters often range from 50mm to 120mm, with hot zones of 300mm or 600mm. However, these can be customized to fit unique sample sizes or throughput requirements.

Selecting the Right Maximum Temperature

A furnace's maximum temperature is dictated by its heating elements. Choosing the right material is critical for performance and longevity.

Common options include:

- Kanthal (A-1) elements for temperatures up to 1200°C.

- Silicon Carbide (SiC) elements for processes up to 1500°C.

- Molybdenum Disilicide (MoSi2) elements for high-temperature applications reaching 1800°C.

Mastering the Internal Environment: Atmosphere Control

Many modern processes require more than just heat; they demand precise control over the gaseous environment inside the furnace. This is one of the most critical areas of customization.

For Standard Air Processing

For applications like drying, baking, or curing, controlling the air is key. Customizations can include adjustable air intakes and exhausts to manage humidity or safely vent volatile organic compounds (VOCs) and fumes generated during heating.

For Oxygen-Sensitive Materials

When working with materials that oxidize at high temperatures, an oxygen-free environment is essential. A laboratory vacuum furnace is designed for this, enabling high-temperature processing with exceptional control over material properties.

For Specific Chemical Reactions

Some processes require a specific, non-reactive environment. For this, furnaces can be constructed with ports and systems for purging with inert gas, such as argon or nitrogen, to prevent unwanted chemical reactions.

Precision and Repeatability: Control and Automation

The sophistication of your furnace's control system determines its ability to execute complex thermal profiles accurately and repeatedly.

Programmable Controllers

Modern furnaces can be equipped with advanced PID (Proportional-Integral-Derivative) or PLC (Programmable Logic Controller) systems. These allow you to program multi-segment heating protocols, defining specific ramp rates, dwell times, and cooling profiles.

User Interfaces and Data Logging

A touchscreen HMI (Human-Machine Interface) provides an intuitive way to adjust parameters and monitor the process. For rigorous quality control and research, optional PC integration allows for remote control and comprehensive data logging.

Critical Safety Mechanisms

Safety is a paramount concern. Essential customizations include over-temperature protection to prevent thermal runaway and auto-shutdown mechanisms that engage if the system deviates from set parameters.

Understanding the Trade-offs and Ancillary Features

Every design choice involves trade-offs between performance, cost, and complexity. Understanding these helps you specify a furnace that is both effective and efficient.

The Role of Insulation and Construction

High-quality thermal insulation is crucial for energy efficiency and temperature stability, reducing heat transfer to the surrounding environment. The furnace body, typically made of steel, is designed to minimize radiant heat loss and ensure structural integrity.

Adding Process-Specific Equipment

Depending on your application, you may need additional integrated equipment.

- Recirculation fans improve temperature uniformity within the chamber.

- Hearth roller rails or load tables can assist with loading and unloading heavy samples.

- Quench tanks can be integrated for processes requiring rapid cooling, such as heat treating metals.

How to Specify the Right Furnace for Your Goal

To ensure you acquire the correct tool, anchor your specifications to your primary application.

- If your primary focus is general drying or curing: Prioritize chamber size, airflow control for fume extraction, and temperature uniformity, which may require recirculation fans.

- If your primary focus is high-temperature materials synthesis: The maximum temperature and corresponding heating element (e.g., MoSi2 for 1800°C) are your most critical specifications.

- If your primary focus is processing oxygen-sensitive materials: A vacuum or inert gas furnace is non-negotiable; focus on the quality of the seals, vacuum pump, and gas purging system.

- If your primary focus is automated, multi-step processes: Invest in an advanced PLC/PID controller with data logging capabilities for process verification and repeatability.

Thoughtful specification is the first and most critical step toward achieving reliable and accurate thermal processing results.

Summary Table:

| Customization Aspect | Key Options |

|---|---|

| Size & Temperature | Chamber volume, tube diameter, hot zone length; heating elements (Kanthal up to 1200°C, SiC up to 1500°C, MoSi2 up to 1800°C) |

| Atmosphere Control | Air intakes/exhausts, vacuum systems, inert gas purging (argon, nitrogen) |

| Control & Automation | PID/PLC controllers, touchscreen HMI, PC integration, data logging |

| Safety & Ancillary | Over-temperature protection, auto-shutdown, recirculation fans, load tables, quench tanks |

Unlock the full potential of your laboratory with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with tailored high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing process control, repeatability, and efficiency. Ready to elevate your thermal processing? Contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is a quartz tube furnace and what is its primary use? Essential for Controlled High-Temp Processing

- How should a quartz tube furnace be cleaned? Essential Steps for Safe, Contamination-Free Maintenance

- What are the key features of a quartz tube furnace? Discover High-Temp Precision for Your Lab

- What are the common applications of quartz tube furnaces? Unlock Precision in High-Temp Processing

- How does the quartz tube furnace minimize heat loss? Double Insulation for Energy Efficiency