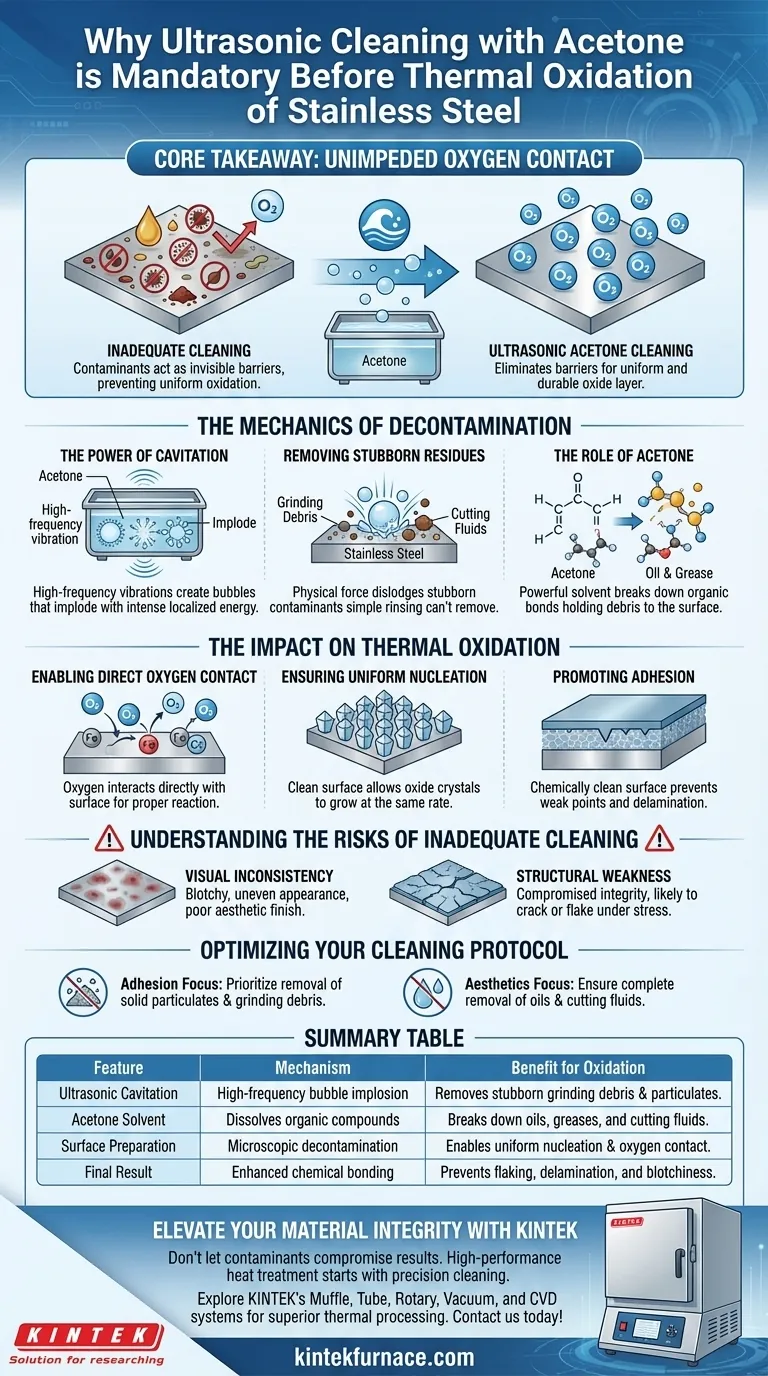

Ultrasonic cleaning with acetone is the mandatory preparatory step that ensures the stainless steel surface is microscopically pristine before it enters a high-temperature furnace. By utilizing high-frequency vibrations to create cavitation, this process aggressively strips away cutting fluids, oils, and organic residues that would otherwise physically block oxygen from reacting with the metal, ensuring a uniform and durable oxide layer.

Core Takeaway Thermal oxidation relies on unimpeded contact between oxygen and the metal substrate. Ultrasonic acetone cleaning eliminates invisible barriers—such as oils and grinding debris—that disrupt the nucleation process, preventing the formation of patchy, non-adherent, or aesthetically flawed oxide films.

The Mechanics of Decontamination

The Power of Cavitation

The core of this cleaning method is the cavitation effect. High-frequency vibrations travel through the acetone, creating millions of microscopic bubbles that rapidly expand and implode.

Removing Stubborn Residues

When these bubbles collapse against the steel surface, they release intense localized energy. This physical force dislodges stubborn contaminants like grinding debris and cutting fluids that simple rinsing cannot remove.

The Role of Acetone

Acetone acts as a powerful solvent for organic materials. It dissolves oils and greases, breaking down the chemical bonds that hold debris to the metal surface.

The Impact on Thermal Oxidation

Enabling Direct Oxygen Contact

For thermal oxidation to work, oxygen must interact directly with the iron and chromium on the stainless steel surface. Any remaining layer of oil or dirt acts as an insulator or barrier.

Ensuring Uniform Nucleation

The quality of the oxide film depends on uniform nucleation. If the surface is clean, the oxide crystals begin growing at the same rate across the entire piece.

Promoting Adhesion

A chemically clean surface allows the oxide film to bond tightly to the substrate. Impurities at the interface create weak points, leading to poor adhesion and potential delamination.

Understanding the Risks of Inadequate Cleaning

Visual Inconsistency

If contaminants are left on the surface, they interfere with the growth of the oxide film. This results in a blotchy, uneven appearance rather than a high-quality decorative finish.

Structural Weakness

Impurities trapped under or within the oxide layer compromise its integrity. A film grown on a dirty surface is more likely to crack or flake off under stress.

Optimizing Your Cleaning Protocol

To ensure the highest quality results in your thermal oxidation process, consider your specific objectives:

- If your primary focus is Adhesion: Prioritize the removal of solid particulates and grinding debris, as these create physical gaps between the metal and the oxide layer.

- If your primary focus is Aesthetics: Ensure the complete removal of oils and cutting fluids, as even a thin organic film will cause discoloration and uneven oxidation rates.

The longevity and beauty of a thermal oxide finish are determined not in the furnace, but in the cleaning tank that precedes it.

Summary Table:

| Feature | Mechanism | Benefit for Oxidation |

|---|---|---|

| Ultrasonic Cavitation | High-frequency bubble implosion | Removes stubborn grinding debris & particulates |

| Acetone Solvent | Dissolves organic compounds | Breaks down oils, greases, and cutting fluids |

| Surface Preparation | Microscopic decontamination | Enables uniform nucleation & oxygen contact |

| Final Result | Enhanced chemical bonding | Prevents flaking, delamination, and blotchiness |

Elevate Your Material Integrity with KINTEK

Don't let surface contaminants compromise your thermal oxidation results. At KINTEK, we understand that high-performance heat treatment starts long before the furnace door closes. Backed by expert R&D and precision manufacturing, we provide a full suite of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your specific research or industrial requirements.

Whether you are aiming for superior oxide adhesion or a flawless aesthetic finish, our high-temperature lab furnaces deliver the thermal precision your projects demand. Contact us today to find the perfect thermal solution for your laboratory and see how KINTEK's expertise can optimize your workflow.

Visual Guide

References

- T. Borowski, Bogusława Adamczyk‐Cieślak. Wear and Corrosion Resistance of Thermally Formed Decorative Oxide Layers on Austenitic Steel. DOI: 10.3390/met15070707

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- Why is a high-precision Mass Flow Controller necessary for E-Ni/m-MgAlOx catalysts? Ensure Precise Gas Dynamics

- What key functions do graphite molds serve during the hot press sintering? Enhance Ti/Al2O3 Composite Quality

- Why is a high-purity graphite crucible essential for magnesium vacuum distillation? Achieve Maximum Purity & Efficiency

- What are the preparation steps for a water circulating vacuum pump? Ensure Optimal Performance and Longevity

- What is the purpose of using a high-purity quartz boat? Ensure Sample Purity in TiO2@C High-Temp Annealing

- Why is a laboratory vacuum drying oven preferred for Al2O3/TiC/SiC(w) mixed slurries? Prevent Oxidation & Agglomeration

- Why is a high vacuum pumping system required for Bi2Se3-Nd2Se3 alloying? Ensure Purity in Rare Earth Synthesis

- What are the considerations for using vacuum-sealed quartz tubes for Ti-xCr-2Ge alloys? Ensure Peak Alloy Performance