A laboratory vacuum drying oven is the superior choice for processing Al2O3/TiC/SiC(w) slurries because it fundamentally alters the drying kinetics by reducing environmental pressure. This allows organic solvents, such as ethanol, to volatilize rapidly at significantly lower temperatures.

By decoupling evaporation from high heat, you avoid the thermal stress that degrades the surface activity of the powder. Most critically, the vacuum environment eliminates the oxygen and high temperatures that would otherwise cause the oxidation and deterioration of sensitive TiC (Titanium Carbide) particles.

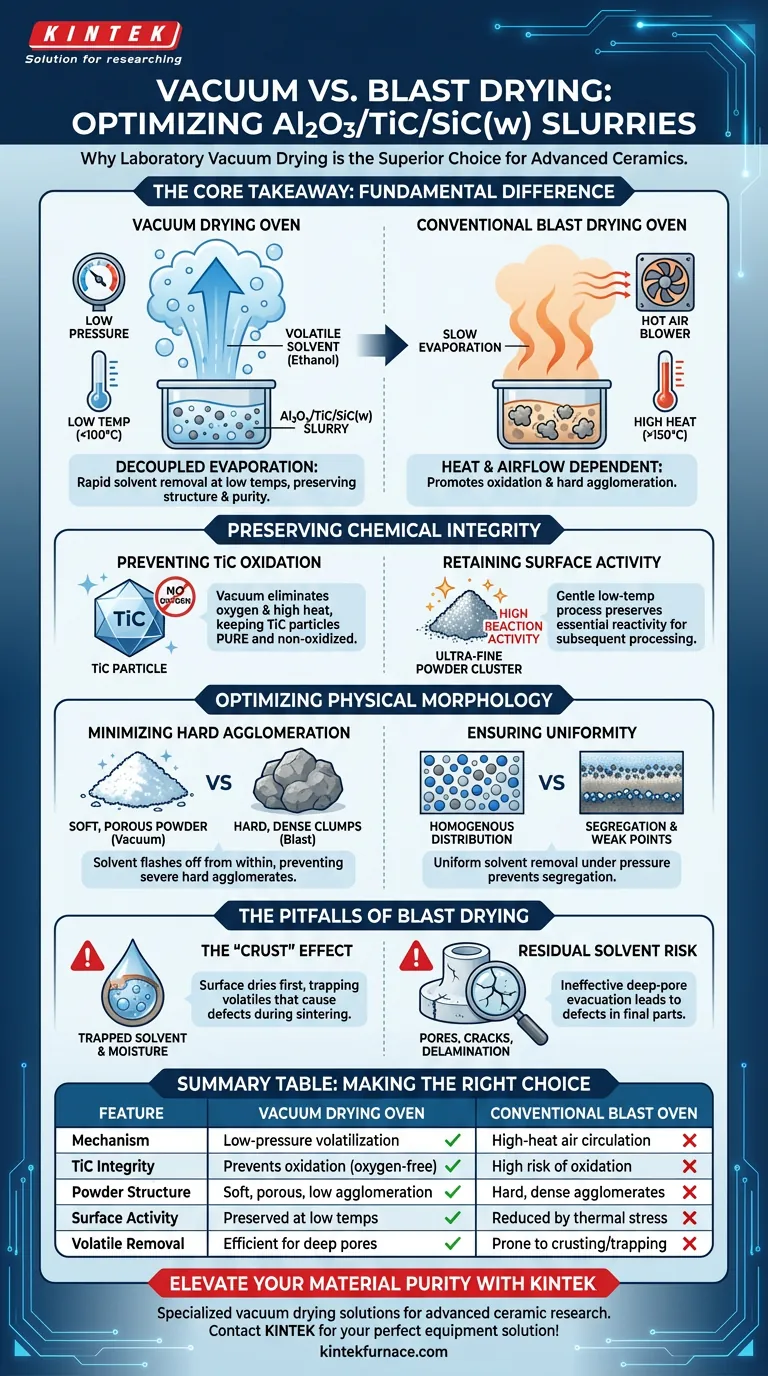

The Core Takeaway Conventional blast drying relies on heat and airflow, which promotes oxidation and hard agglomeration in ceramic slurries. Vacuum drying utilizes negative pressure to lower the solvent's boiling point, preserving the chemical purity of ultra-fine powders and ensuring a loose, porous structure essential for high-quality sintering.

Preserving Chemical Integrity

The primary driver for choosing a vacuum oven over a blast oven is the chemical sensitivity of the slurry components, specifically the Titanium Carbide (TiC).

preventing Oxidation of TiC

TiC particles are highly susceptible to oxidation, particularly when exposed to the high-temperature air circulation typical of blast drying ovens.

By operating in a vacuum, you remove the oxygen source and lower the thermal requirement. This dual mechanism ensures the TiC particles remain pure and do not degrade into oxides, which would compromise the material properties of the final composite.

Retaining Surface Activity

High temperatures can "deaden" the surface activity of ultra-fine powders.

Vacuum drying facilitates evaporation at mild temperatures. This gentle process preserves the high reaction activity of the original powder, which is critical for the reactivity and bonding required during subsequent processing stages.

Optimizing Physical Morphology

Beyond chemistry, the physical structure of the dried powder dictates the quality of the final ceramic component.

Minimizing Hard Agglomeration

In a conventional blast oven, solvent evaporates from the surface of the slurry droplet, creating strong capillary forces that pull particles together into dense, hard clumps (agglomerates).

Vacuum drying causes the solvent to flash off rapidly from within the bulk material. This prevents the formation of severe hard agglomerates, resulting in a looser, softer powder that is easier to process.

Ensuring Uniformity

Because the solvent is removed uniformly under pressure rather than via directional airflow, the mixture maintains a homogenous distribution.

This uniformity ensures that the Al2O3, TiC, and SiC whiskers remain evenly dispersed, preventing the segregation that can lead to structural weak points.

Understanding the Trade-offs: Common Pitfalls

While vacuum drying is preferred, understanding the risks of the alternative—blast drying—highlights why the switch is necessary.

The "Crust" Effect of Blast Drying

Blast ovens often dry the surface of a slurry first, forming a hard crust. This traps moisture and solvent inside the material.

If these trapped volatiles are not removed, they will expand during the sintering phase, causing pores, cracks, or delamination defects in the final ceramic part.

The Risk of Residual Solvents

Vacuum environments are far more effective at evacuating solvents trapped deep within the microscopic pores of the powder clusters.

Failure to remove these solvents completely—a common issue with standard thermal drying—leads to defects during compression molding and sintering.

Making the Right Choice for Your Goal

The specific drying method you choose dictates the ceiling of your material's performance.

- If your primary focus is Chemical Purity: Prioritize vacuum levels that allow solvent evaporation at ambient or near-ambient temperatures to completely eliminate oxidation risks for TiC.

- If your primary focus is Sintering Density: Ensure the vacuum drying cycle is long enough to evacuate all deep-pore solvents, preventing gas-induced defects during the high-heat sintering stage.

By utilizing vacuum drying, you are not just removing liquid; you are actively engineering the microstructure and chemistry of the precursor for peak performance.

Summary Table:

| Feature | Vacuum Drying Oven | Conventional Blast Oven |

|---|---|---|

| Mechanism | Low-pressure volatilization | High-heat air circulation |

| TiC Integrity | Prevents oxidation (oxygen-free) | High risk of oxidation/degradation |

| Powder Structure | Soft, porous, low agglomeration | Hard, dense agglomerates |

| Surface Activity | Preserved at low temperatures | Reduced due to thermal stress |

| Volatile Removal | Efficient even for deep pores | Prone to surface crusting/trapping |

Elevate Your Material Purity with KINTEK

Don't let oxidation or hard agglomeration compromise your advanced ceramic research. Backed by expert R&D and manufacturing, KINTEK offers specialized vacuum drying solutions alongside our Muffle, Tube, Rotary, and CVD systems. Whether you are processing Al2O3/TiC/SiC(w) slurries or developing custom lab-scale materials, our customizable high-temperature furnaces are designed to meet your most rigorous technical requirements.

Ready to optimize your drying kinetics? Contact KINTEK today to find your perfect equipment solution!

Visual Guide

References

- Song‐Jeng Huang, Murugan Subramani. Mechanical and Corrosion Tests for Magnesium–Zinc/Ti-6Al-4V Composites by Gravity Casting. DOI: 10.3390/ma17081836

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- Why is rhenium selected as a material for sample capsules? Key Benefits for High-Temperature Experimental Success

- What temperature range can graphite crucible furnaces withstand? Achieve Extreme Heat for High-Melting Metals

- What properties make quartz tubes ideal for heat treatment processes? Unlock High-Temperature Purity and Stability

- What are the technical considerations for using alumina crucibles? Optimize High-Entropy Alloy Purity & Microstructure

- What necessary conditions does a vacuum chamber provide for vapor deposition? Achieve High-Purity Nanofluid Synthesis

- Why are a press and pelletizing molds necessary when preparing pellets for magnesium smelting? Ensure Smelting Efficiency and Control

- How do digital mass flow controllers (MFC) maintain a constant smelting atmosphere? Ensure Precise Gas Control

- What role do graphite molds play in the Spark Plasma Sintering (SPS)? Enhance Alumina Composite Performance