In magnesium smelting, a press and pelletizing molds are not merely for shaping materials; they are essential for engineering the physical and chemical conditions required for an efficient and controllable reaction. They transform loose, unpredictable powdered raw materials into dense, uniform pellets with the mechanical strength needed to withstand the intense furnace environment, ensuring predictable outcomes.

The core purpose of pelletizing is to convert raw material powder into engineered units. This guarantees the structural integrity, uniform heat distribution, and predictable gas flow necessary for stable and controllable chemical reactions within the smelting furnace.

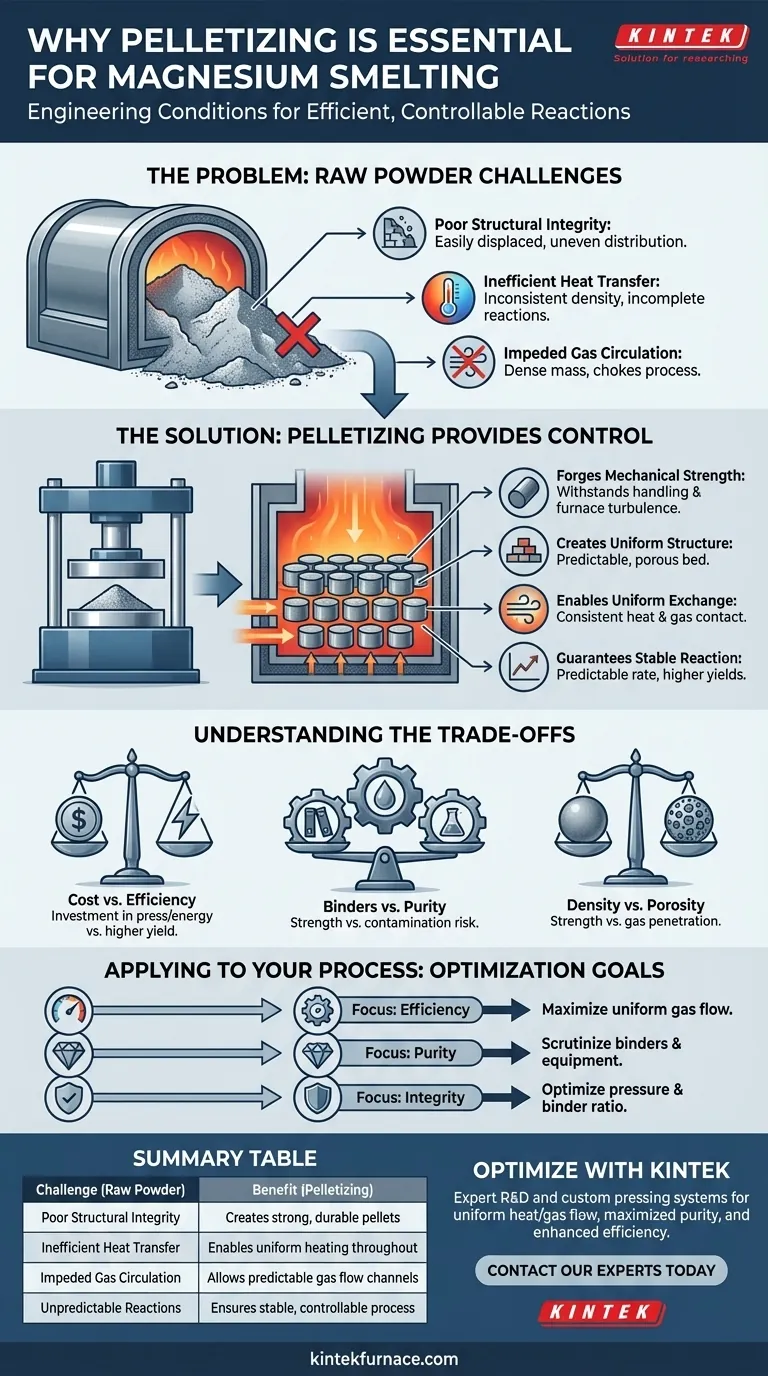

The Problem with Raw Powder

Using raw, uncompacted powder directly in a smelting furnace presents significant challenges that make the process inefficient and unreliable. The goal of pelletizing is to overcome these inherent limitations.

Poor Structural Integrity

Loose powder lacks the strength to maintain its form. Inside a furnace, it would be easily displaced, creating an uneven distribution of material that makes any controlled process impossible.

Inefficient Heat Transfer

A pile of powder has inconsistent density. The outer layers would be exposed to intense heat while the core remains insulated and cool, leading to incomplete and uneven chemical reactions.

Impeded Gas Circulation

Powder packs into a dense, non-porous mass. This structure prevents the hot gases, which are critical for the calcination and reduction reactions, from circulating effectively. This essentially chokes the process and severely limits its efficiency.

How Pelletizing Provides Control

A press and mold system systematically addresses each of the problems associated with raw powder, turning an unpredictable raw material into a standardized process input.

Forging Mechanical Strength

The primary function of the press is to compact the powder into a solid pellet. This process imparts significant mechanical strength, ensuring the pellets do not crumble or disintegrate during handling or within the turbulent environment of the furnace.

Creating a Uniform Stacking Structure

Because each pellet has a specific, consistent shape, they stack together in a predictable way. This creates a regular, porous bed of material, much like a neatly stacked pile of bricks compared to a heap of sand.

Enabling Uniform Heat and Gas Exchange

The regular gaps between the stacked pellets form channels. These channels allow hot gases to flow evenly throughout the material bed, ensuring every pellet is heated uniformly and comes into consistent contact with the reactant gases.

Guaranteeing a Stable Reaction

This combination of strength, uniform stacking, and efficient heat and gas transfer is the prerequisite for a stable process. It ensures the crucial calcination and reduction reactions proceed at a predictable and controllable rate, leading to higher yields and consistent product quality.

Understanding the Trade-offs

While pelletizing is critical, it is an additional process step with its own set of considerations that must be managed for optimal results.

Energy and Equipment Costs

Pressing and pelletizing machinery represents a significant capital investment. The process itself also consumes energy, which adds to the operational cost of production. This cost must be justified by the increased efficiency and yield in the smelting stage.

The Role of Binders

In some cases, a binding agent may be required to achieve the desired pellet strength. The choice of binder is critical, as an improper one could introduce impurities into the final magnesium product.

Density vs. Porosity

There is a crucial balance to strike. The pellet must be dense enough to be mechanically strong, but it must also retain some internal porosity to allow reactant gases to penetrate beyond the surface and react with the material inside.

Applying This to Your Process

Your approach to pelletizing should be guided by your primary operational objective. Fine-tuning the process parameters allows you to optimize for specific outcomes.

- If your primary focus is process efficiency: Prioritize creating pellets with a shape and density that maximizes uniform gas flow, ensuring the fastest and most complete chemical reactions.

- If your primary focus is product purity: Scrutinize any binding agents and ensure the pressing process itself does not introduce contaminants from equipment wear.

- If your primary focus is structural integrity: Concentrate on achieving the optimal pressure and potential binder ratio to create robust pellets that will not degrade under thermal or mechanical stress in the furnace.

Ultimately, mastering the pelletizing stage provides fundamental control over the performance, efficiency, and quality of the entire magnesium smelting process.

Summary Table:

| Challenge with Raw Powder | Benefit of Pelletizing |

|---|---|

| Poor Structural Integrity | Creates strong, durable pellets |

| Inefficient Heat Transfer | Enables uniform heating throughout |

| Impeded Gas Circulation | Allows predictable gas flow channels |

| Unpredictable Reactions | Ensures stable, controllable process |

Optimize Your Magnesium Smelting Process with KINTEK

Mastering the pelletizing stage is fundamental to achieving a stable, efficient, and high-yield magnesium smelting operation. The right equipment is critical for creating pellets with the precise mechanical strength, density, and porosity required for your specific needs.

Backed by expert R&D and manufacturing, KINTEK offers a range of robust pressing systems and custom pelletizing molds designed to withstand the demands of high-temperature smelting. Our solutions help you:

- Achieve uniform heat distribution and gas flow for complete, predictable reactions.

- Maximize product purity by minimizing contamination risks.

- Enhance process efficiency with durable, consistent pellets that reduce waste.

Whether you prioritize efficiency, purity, or structural integrity, we can customize a solution for your unique process requirements.

Contact our experts today to discuss how our pelletizing equipment can improve your smelting control and outcomes!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- How does the use of vacuum in hot-pressing affect the material processing? Achieve Denser, Purer, and Stronger Materials

- What are the key applications of vacuum pressing in composite material processing? Enhance Material Quality and Shape Complexity

- What factors should be considered when choosing between hot pressing and cold compacting and sintering? Optimize Your Material Manufacturing

- How does Vacuum Hot Press equipment contribute to the energy and power generation sector? Boost Efficiency and Durability

- What is a vacuum press and what are its primary uses? Unlock High-Performance Material Processing